Strength effect and mechanism analysis of MICP-solidified coal ash

-

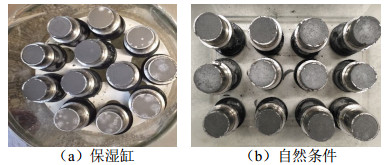

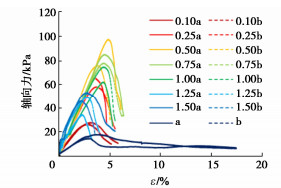

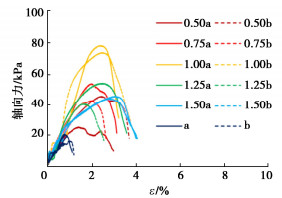

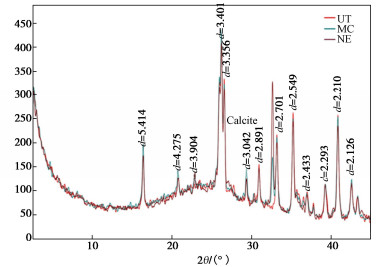

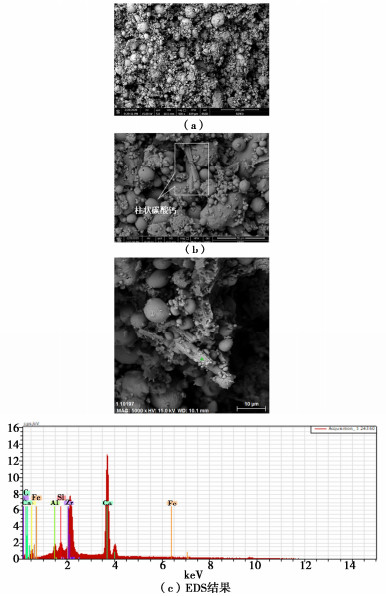

摘要: 粉煤灰具有颗粒细、相对质量密度小、孔隙比大的特点,为了实现粉煤灰的有效利用和粉尘污染控制,应用微生物诱导碳酸盐沉淀(MICP)方法,考虑自然蒸发和湿缸养护两种条件,研究了微生物反应机理、强化特性及影响因素。结果表明:①微生物在粉煤灰中产生的碳酸钙为方解石,含量从7%最大增加到15.3%;②MICP湿缸固化条件下,无侧限抗压强度最大提高6.55倍,达97.63 kPa;③固化强度随营养物浓度的增加表现为先增大后降低,保湿缸和自然蒸发条件下的最佳营养浓度分别为0.5 mol/L和1.0 mol/L;④微生物固化粉煤灰可以减少内部水分损失,保水效果明显,还具有良好的抑尘应用前景。Abstract: The coal ash has the characteristics of fine particles, small specific gravity and large pore ratio. In order to achieve effective utilization of the coal ash and dust pollution control, the microbial induced carbonate precipitation (MICP) method is used, considering natural evaporation and wet cylinder maintenance conditions, to study the mechanism of microbial response, strengthening characteristics and influencing factors. The results show that: (1) The calcite is the calcium carbonate produced by microorganisms in the coal ash, and the content increases from 7% to 15.3%. (2) Under the MICP wet cylinder curing conditions, the maximum unconfined compressive strength increases by 6.55 times, reaching 97.63 kPa. (3) The solidification strength first increases and then decreases with the increase of the nutrient concentration, and the optimal nutrient concentrations under moisturizing cylinder and natural evaporation conditions are 0.5 and 1.0 mol/L, respectively. (4) The microbial-derived calcium carbonate can reduce the water loss in ash samples and has a significant water retention effect, indicating good prospects for dust suppression applications.

-

Keywords:

- MICP /

- coal ash /

- strength effect /

- mechanism analysis

-

-

表 1 不同组别的试样中营养盐浓度及质量

Table 1 Nutrient concentration and mass in samples of different groups

试验组别 浓度 氯化钙 尿素 a 0.10 1.32 0.54 b 0.25 3.31 1.35 c 0.50 6.62 2.70 d 0.75 9.92 4.05 e 1.00 13.23 5.41 f 1.25 16.54 6.76 g 1.50 19.85 8.11 表 2 试验设计

Table 2 Experimental design

组别 营养液浓度/(mol·L-1) 掺比 养护龄期/d 1 0.10 粉煤灰∶菌液=2∶1 7 2 0.25 粉煤灰∶菌液=2∶1 7 3 0.50 粉煤灰∶菌液=2∶1 7 4 0.75 粉煤灰∶菌液=2∶1 7 5 1.00 粉煤灰∶菌液=2∶1 7 6 1.25 粉煤灰∶菌液=2∶1 7 7 1.50 粉煤灰∶菌液=2∶1 7 表 3 保湿缸养护条件下试样强度

Table 3 Sample strength under curing conditions of wet cylinder maintenance

营养盐浓度/(mol·L-1) 试样质量/g 峰值应力/kPa 平均峰值应力/kPa 养护前后含水率减少值/% 0.1 126.3 27.23 28.10 2.03 126.0 28.98 2.05 0.25 134.8 68.17 64.36 4.36 134.2 60.54 3.13 0.5 139.7 102.58 90.78 8.10 137.7 78.97 7.84 0.75 137.1 89.14 85.37 6.29 137.1 81.61 6.88 1 134.5 65.11 71.68 7.17 133.2 78.24 7.60 1.25 132.9 54.87 50.98 7.79 130.6 47.09 9.38 1.5 137.5 35.23 42.96 7.85 138.1 50.69 7.64 对照组 133.33 18.90 17.14 16.25 131.68 15.37 16.28 表 4 自然养护条件下试样强度

Table 4 Sample strength under natural evaporation curing conditions

营养盐浓度/(mol·L-1) 试样质量/g 峰值应力/kPa 平均峰值应力/kPa 养护前后含水率减少值/% 0.5 134.43 25.95 36.41 25.35 135.2 46.85 25.13 0.75 140.61 54.96 49.34 23.62 138.6 43.73 25.32 1 130.74 80.35 78.06 24.30 133.54 75.77 23.56 1.25 133.69 55.50 48.42 24.05 139.7 41.33 25.37 1.5 134.41 47.18 46.25 21.94 135.66 45.33 22.29 对照组 133.18 21.07 18.87 45.10 133.00 16.66 45.64 表 5 粉煤灰矿物含量

Table 5 Mineral content of fly ash

材料 矿物含量/% 石英 钾长石 方解石 莫来石 黏土矿物 对照组 8.8 5.6 7.0 75.3 3.3 缸湿 7.0 0.5 18.9 71.2 2.4 自然蒸发 6.0 0.6 15.3 75.2 2.9 -

[1] KOUKOUZAS N K, ZENG R S, PERDIKATSIS V, et al. Mineralogy and geochemistry of Greek and Chinese coal fly ash[J]. Fuel, 2006, 85: 2301-2309. doi: 10.1016/j.fuel.2006.02.019

[2] KUCHARSKI E S, CHOW F C, PRICE G P, et al. Investigations into the stabilisation of ash using the calcite in situ precipitation system[J]. Classical Rev, 2000, 24: 523-549.

[3] DEJONG J T, MORTENSEN B M, MARTINEZ B C, et al. Bio-mediated soil improvement[J]. Ecol Eng, 2010, 36: 197-210. doi: 10.1016/j.ecoleng.2008.12.029

[4] DEJONG J T, FRITZGES M B, NÜSSLEIN K. Microbially induced cementation to control sand response to undrained shear[J]. J Geotech Geoenviron Eng, 2006, 132(11): 1381-1392. doi: 10.1061/(ASCE)1090-0241(2006)132:11(1381)

[5] SAFAVIZADEH S, MONTOYA B M, GABR M A. Effect of microbial induced calcium carbonate precipitation on compressibility and hydraulic conductivity of fly ash[C]// IFCEE 2018 GSP, 2018, 296: 69-79.

[6] SAFAVIZADEH S, MONTOYA B M, GABR M A. Treating coal ash with microbial-induced calcium carbonate precipitation[J]. J Geotech Geoenviron Eng, 2018, 144(11): 02818003-1. doi: 10.1061/(ASCE)GT.1943-5606.0001956

[7] MONTOYA B M, SAFAVIZADEH S, GABR M A. Enhancement of coal ash compressibility parameters using microbial-induced carbonate precipitation[J]. J Geotech Geoenviron Eng, 2019, 145(5): 04019018. doi: 10.1061/(ASCE)GT.1943-5606.0002036

-

期刊类型引用(2)

1. 吴雄华,邹振杰. 生物炭-水泥固化膨胀土物理力学特性及其影响机理研究. 公路. 2025(04): 409-416 .  百度学术

百度学术

2. 胡波,李浩洋,童军,王卫,查恒,夏锐. 磷石膏改性膨胀土工程特性演变规律试验研究. 人民长江. 2025(05): 156-161 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: