Finite element numerical simulation of single pile under horizontal cyclic loading considering softening effect of soft soil

-

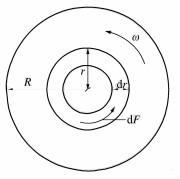

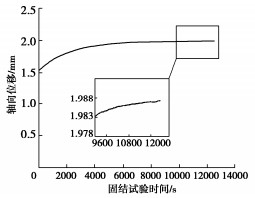

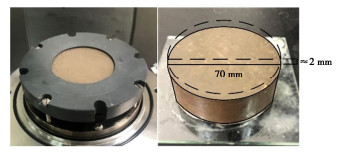

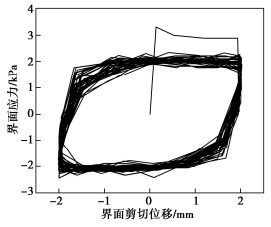

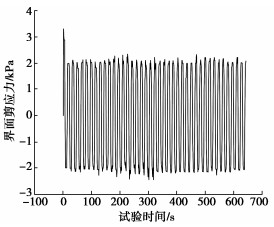

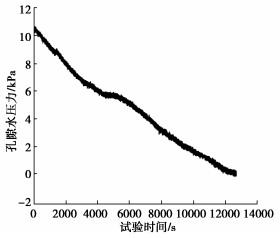

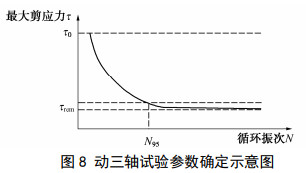

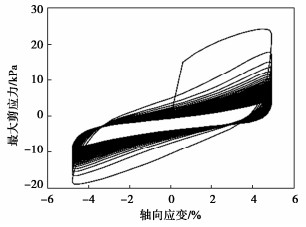

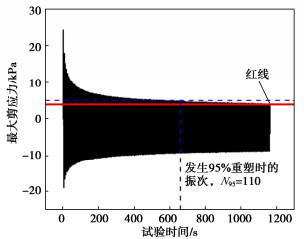

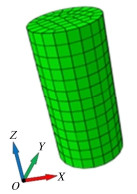

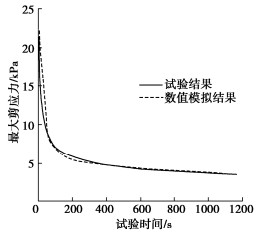

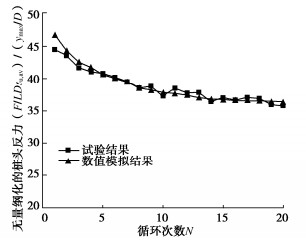

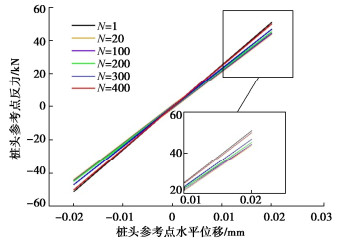

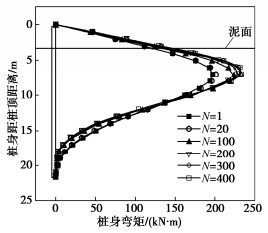

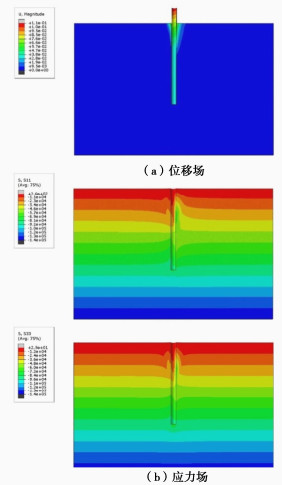

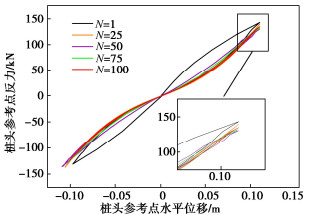

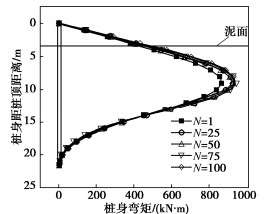

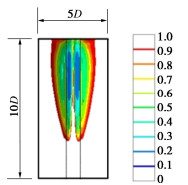

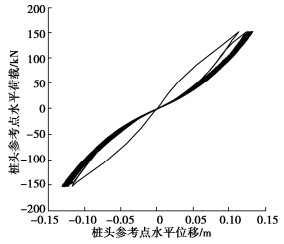

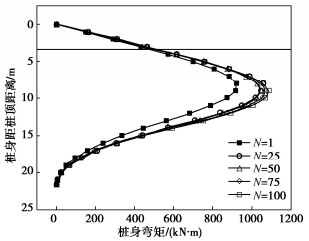

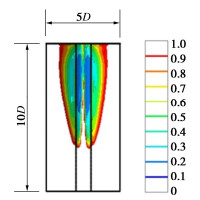

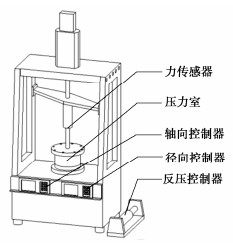

摘要: 海洋环境中的单桩基础受到风、波浪、海流等循环荷载长期作用,在循环荷载作用下桩和软土之间的接触面上的剪应力和桩周软土的剪切强度均会降低,从而影响桩基的承载特性。结合试验手段,通过界面剪切试验获得了Q235钢与天津滨海淤泥质软黏土之间的循环界面摩擦系数,通过动三轴试验获得了天津滨海淤泥质软黏土的循环软化参数,为量化桩土界面循环摩擦特性和桩周软土循环软化特性提供了一种参数获取方法。在此基础上,结合可考虑软土应变软化效应的软土本构模型,建立了不排水软基上单桩基础受水平循环荷载作用的有限元模型,研究了单桩在受到水平循环荷载作用下的桩头位移-反力响应与桩身截面弯矩的发展规律,并获得了循环荷载作用后桩周土体软化区域的发展规律。计算结果表明:随着循环振次的增加,桩基周围土体软化区域不断发展,高水平循环位移作用下土体软化区域沿深度发展程度高,对应桩身最大弯矩出现位置下移。Abstract: The single pile foundation in marine environment is subjected to long-term cyclic loading due to wind, waves and currents. Under the cyclic loading, the interface shear stress between pile and soft soil and the shear strength of soft soil around the pile will decrease, thus affecting the bearing characteristics of pile foundation. The cyclic interface friction coefficient between Q235 steel and Tianjin coastal soft clay is obtained through the interface shear tests, and the cyclic softening parameters of Tianjin coastal soft clay are obtained through the dynamic triaxial tests, which provides a method to obtain the parameters for quantifying the cyclic friction characteristics of pile-soil interface and the cyclic softening characteristics of soft soil around piles. On this basis, a finite element model for single pile foundation in undrained soft foundation under horizontal cyclic loading is established with the combination of the constitutive model for soft soil, which can consider the strain softening effect of soft soil. The development laws of pile head displacement and reaction response and pile section bending moment under horizontal cyclic loading are studied while the development law of softening area of soil around the pile under cyclic loading is obtained. The calculated results show that the softening area of soil around the pile foundation develops continuously with the increase of cyclic number. Meanwhile, the softening zone of soil has a high degree of development along the depth under the action of high horizontal cyclic displacement. The position corresponding to the maximum bending moment of pile body moves downward.

-

-

表 1 试验所用黏土的物理力学性质

Table 1 Physical and mechanical properties of clay

含水率w/% 塑限wL/% 液限wP/% 相对质量密度Gs 密度ρ

/(g·cm-3)孔隙比e 不排水抗剪强度cu/kPa 17 18.6 34.2 2.72 1.89 0.665 15 -

[1] MCCLELLAND B, FOCHT J. Soil modulus for laterally loaded piles[J]. Journal of the Soil Mechanics and Foundations Division, 1956, 82(4): 1–22.

[2] MATLOCK H. Correlation for design of laterally loaded piles in soft clay[C]// Proceeding of 2nd Offshore Technology Conference, 1970, Houston.

[3] MOSS R E S, CALIENDO J A, ANDERSON L R. Investigation of a cyclic laterally loaded model pile group[J]. Soil Dynamics and Earthquake Engineering, 1998, 17(7/8): 519–523.

[4] 田平, 王惠初. 黏土中横向周期性荷载桩的P–Y曲线统一法[J]. 河海大学学报, 1993, 21(1): 9–14. doi: 10.3321/j.issn:1000-1980.1993.01.002 TIAN Ping, WANG Hui-chu. A unified method of P-Y curves for laterlly and periodically loaded piles in clay[J]. Journal of Hohai University (Natural Sciences), 1993, 21(1): 9–14. (in Chinese) doi: 10.3321/j.issn:1000-1980.1993.01.002

[5] 张陈蓉, 俞剑, 黄茂松. 软黏土中水平循环荷载作用下刚性短桩的p–y曲线分析[J]. 岩土工程学报, 2011, 33(增刊2): 78–82. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2011S2015.htm ZHANG Chen-rong, YU Jian, HUANG Mao-song. P–y curve analyses of rigid short piles subjected to lateral cyclic load in soft clay[J]. Chinese Journal of Geotechnical Engineering, 2011, 33(S2): 78–82. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2011S2015.htm

[6] Recommended Practice for Planning, Designingand Constructing Fixed Offshore Platforms-Working Stress Design: API RP—2A—WSD[S]. 2002.

[7] 码头结构设计规范: JTS 167—2018[S]. 2018. Design Code for Wharf Structures: JTS 167—2018[S]. 2018. (in Chinese)

[8] 刘晓强, 赵楠, 夏开文, 等. 循环荷载作用下桩周土体强度弱化特性试验研究[J]. 地震工程学报, 2014, 36(4): 987–990. doi: 10.3969/j.issn.1000-0844.2014.04.0987 LIU Xiao-qiang, ZHAO Nan, XIA Kai-wen, et al. Test and study on strength weakening behavior of soil around a pile under cyclic loading[J]. China Earthquake Engineering Journal, 2014, 36(4): 987–990. (in Chinese) doi: 10.3969/j.issn.1000-0844.2014.04.0987

[9] 李森, 俞剑, 黄茂松. 饱和黏土中不同刚度单桩水平循环加载离心试验[J]. 岩土工程学报, 2021, 43(5): 948–954. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202105024.htm LI Sen, YU Jian, HUANG Mao-song. Centrifuge test on single pile with different rigidities in saturated clay under cyclic lateral loading[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(5): 948–954. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202105024.htm

[10] 朱斌, 杨永垚, 余振刚, 等. 海洋高桩基础水平单调及循环加载现场试验[J]. 岩土工程学报, 2012, 34(6): 1028–1037. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201206012.htm ZHU Bin, YANG Yong-yao, YU Zhen-gang, et al. Field tests on lateral monotonic and cyclic loadings of offshore elevated piles[J]. Chinese Journal of Geotechnical Engineering, 2012, 34(6): 1028–1037. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201206012.htm

[11] 俞剑, 黄茂松, 张陈蓉. 黏土中两种不同直径单桩水平循环加载模型试验与分析[J]. 岩土力学, 2016, 37(4): 973–980. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201604009.htm YU Jian, HUANG Mao-song, ZHANG Chen-rong. Model tests and analysis of single piles with two different diameters subjected to cyclic lateral loadings in clay[J]. Rock and Soil Mechanics, 2016, 37(4): 973–980. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201604009.htm

[12] ZHANG C R, WHITE D, RANDOLPH M. Centrifuge modeling of the cyclic lateral response of a rigid pile in soft clay[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2011, 137(7): 717–729. doi: 10.1061/(ASCE)GT.1943-5606.0000482

[13] 夏华盛, 张陈蓉, 俞剑, 等. 海上风电桩基水平承载力循环衰减二维简化分析[J]. 岩土力学, 2012, 33(增刊1): 303–308. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2012S1049.htm XIA Hua-sheng, ZHANG Chen-rong, YU Jian, et al. 2D simplified analysis of cyclic degradation of lateral bearing capacity for the pile foundation of offshore wind turbine[J]. Rock and Soil Mechanics, 2012, 33(S1): 303–308. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX2012S1049.htm

[14] 黄茂松, 马昊, 李森, 等. 软黏土中水平受荷桩的静力和循环p–y曲线[J]. 岩土工程学报, 2017, 39(增刊2): 9–12. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2017S2004.htm HUANG Mao-song, MA Hao, LI Sen, et al. Static and cyclic p-y curves for laterally loaded piles in soft clay[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(S2): 9–12. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2017S2004.htm

[15] RAJASHREE S S, SUNDARAVADIVELU R. Degradation model for one-way cyclic lateral load on piles in soft clay[J]. Computers and Geotechnics, 1996, 19(4): 289–300. doi: 10.1016/S0266-352X(96)00008-0

[16] EINAV I, RANDOLPH M F. Combining upper bound and strain path methods for evaluating penetration resistance[J]. International Journal for Numerical Methods in Engineering, 2005, 63(14): 1991–2016. doi: 10.1002/nme.1350

[17] XIAO Z, TIAN Y H, GOURVENEC S. A practical method to evaluate failure envelopes of shallow foundations considering soil strain softening and rate effects[J]. Applied Ocean Research, 2016, 59: 395–407. doi: 10.1016/j.apor.2016.06.015

[18] ZHOU H, RANDOLPH M F. Numerical investigations into cycling of full-flow penetrometers in soft clay[J]. Géotechnique, 2009, 59(10): 801–812. doi: 10.1680/geot.7.00200

[19] CHEUK C Y, WHITE D J. Modelling the dynamic embedment of seabed pipelines[J]. Géotechnique, 2011, 61(1): 39–57. doi: 10.1680/geot.8.P.148

[20] DONNA D A, FERRARI A, LALOUI L. Experimental investigations of the soil–concrete interface: physical mechanisms, cyclic mobilization, and behaviour at different temperatures[J]. Canadian Geotechnical Journal, 2016, 53(4): 659–672. doi: 10.1139/cgj-2015-0294

[21] HAMMOUD F, BOUMEKIK A. Experimental study of the behaviour of interfacial shearing between cohesive soils and solid materials at large displacement[J]. Asian Journal of Civil Engineering (Building and Housing), 2006, 7(1): 63–80.

[22] 土工试验方法标准: GB/T 50123—2019[S]. 2019. Standard for Geotechnical Testing Method: GB/T 50123—2019[S]. 2019. (in Chinese)

[23] DAYAL U, ALLEN J H. The effect of penetration rate on the strength of remolded clay and sand samples[J]. Canadian Geotechnical Journal, 1975, 12(3): 336–348. doi: 10.1139/t75-038

[24] GRAHAM J, CROOKS J H A, BELL A L. Time effects on the stress-strain behaviour of natural soft clays[J]. Géotechnique, 1983, 33(3): 327–340. doi: 10.1680/geot.1983.33.3.327

[25] CHANEY R C, DEMARS K R, BISCONTIN G, et al. Influence of peripheral velocity on vane shear strength of an artificial clay[J]. Geotechnical Testing Journal, 2001, 24(4): 423–429. doi: 10.1520/GTJ11140J

-

期刊类型引用(16)

1. 张培森,许大强,颜伟,张晓乐,董宇航,赵铭. 应力-渗流耦合作用下不同卸荷路径对砂岩损伤特性及能量演化规律的影响研究. 岩土力学. 2024(02): 325-339 .  百度学术

百度学术

2. 杜佳慧,李文璞,常悦,王泽,王涛. 卸荷砂岩渐进破坏及渗透特性的中间主应力效应研究. 煤矿安全. 2024(06): 19-29 .  百度学术

百度学术

3. 季宁,李世倩,任罡,胡晓丽,陶红鑫,魏蔚,孙吕祎,屠骏,张梦梦,陶锴. 基于声发射乐谱化Frechet编码的变电站主变压器基底渗水损伤监测. 中国测试. 2023(02): 42-49 .  百度学术

百度学术

4. 张培森,许大强,颜伟,胡昕,李霄,方家鑫,鞠照强,赵铭. 不同围压下峰后循环载荷对砂岩力学及渗流特性的影响研究. 煤炭科学技术. 2023(07): 94-105 .  百度学术

百度学术

5. 张培森,许大强,颜伟,胡昕,张晓乐,董宇航,方家鑫. 不同初始损伤程度下循环加卸围压对岩石劣化及渗流特性的影响研究. 岩石力学与工程学报. 2023(09): 2109-2124 .  百度学术

百度学术

6. 张培森,侯季群,赵成业,李腾辉. 不同应力状态下底板岩体渗流特性分析研究. 煤炭科学技术. 2022(01): 127-133 .  百度学术

百度学术

7. 刘先珊,潘玉华,李满,康治勇,周虎,乔士豪. 循环加卸载过程中的水化页岩渗透特性. 煤炭学报. 2022(S1): 103-114 .  百度学术

百度学术

8. 张培森,许大强,张睿,张晓乐,董宇航,慕卫丽. 不同围压及循环载荷下砂岩的渗流、力学特性试验研究. 岩石力学与工程学报. 2022(12): 2432-2450 .  百度学术

百度学术

9. 刘先珊,周虎,张立君,李满,乔士豪,潘玉华,侯泽林,郝梓宇. 酸处理页岩的损伤效应与力学特性. 兰州大学学报(自然科学版). 2022(06): 831-841+846 .  百度学术

百度学术

10. 刘先珊,李满,张立君,王科,李涛,曾南豆. 储层砂岩的物性差异对其渗透特性的影响. 应用基础与工程科学学报. 2022(06): 1505-1521 .  百度学术

百度学术

11. 王文才,李雨萌. 煤矿地下水库人工坝体构筑材料适用性研究. 煤炭工程. 2020(03): 118-121 .  百度学术

百度学术

12. 张培森,赵成业,侯季群,李腾辉. 高温与不同水压下深部砂岩渗透特性试验研究. 岩石力学与工程学报. 2020(06): 1117-1128 .  百度学术

百度学术

13. 张培森,赵成业,侯季群,李腾辉,张雪. 温度-应力-渗流耦合条件下红砂岩渗流特性试验研究. 岩石力学与工程学报. 2020(10): 1957-1974 .  百度学术

百度学术

14. 张培森,侯季群,赵成业,李腾辉. 不同围压不同损伤程度红砂岩渗流特性试验研究. 岩石力学与工程学报. 2020(12): 2405-2415 .  百度学术

百度学术

15. 由爽,李飞,纪洪广,王洪涛,张乘菡. 高应力高水压下深部花岗岩力学响应联动机制. 煤炭学报. 2020(S1): 219-229 .  百度学术

百度学术

16. 张俊文,宋治祥,范文兵,丁露江,姚子祥,霍英昊,宿文桐. 真三轴条件下砂岩渐进破坏力学行为试验研究. 煤炭学报. 2019(09): 2700-2709 .  百度学术

百度学术

其他类型引用(19)

下载:

下载: