On-site flexural toughness of wet-sprayed concrete with silica fume and steel fibers

-

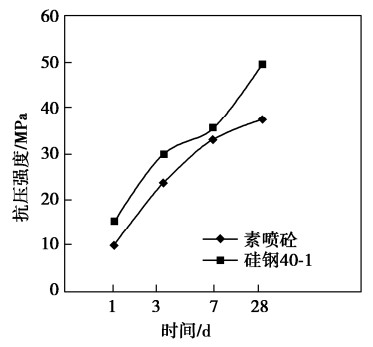

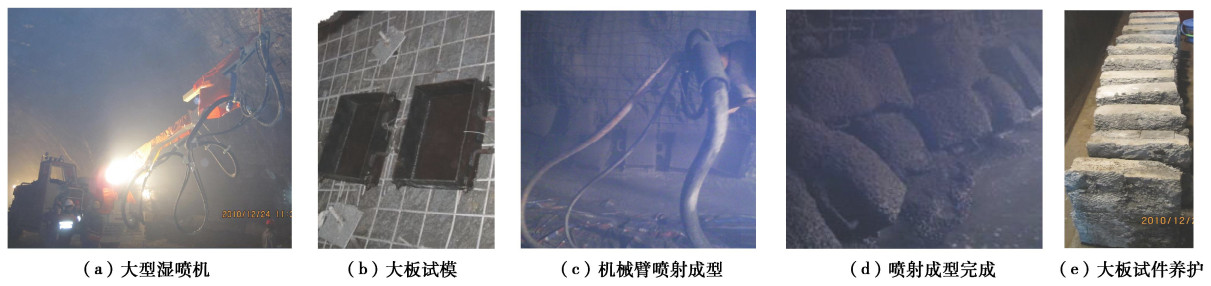

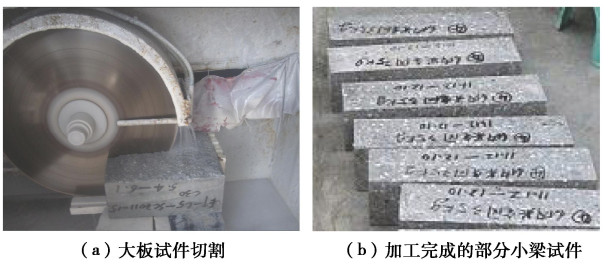

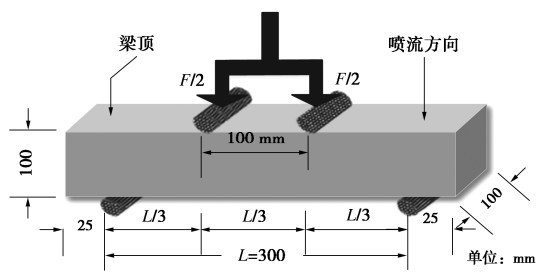

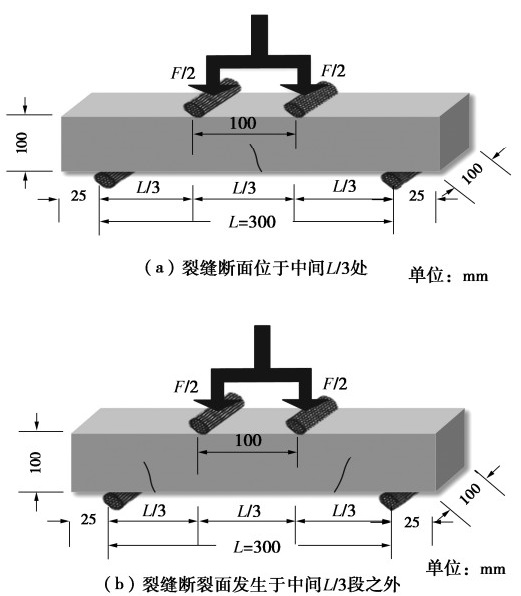

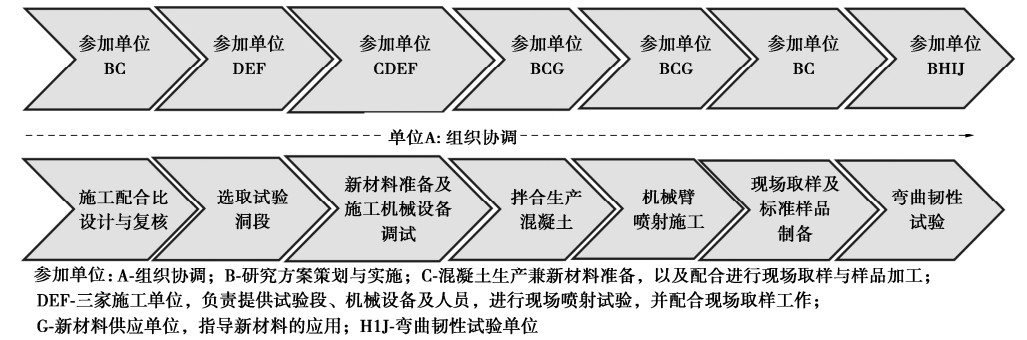

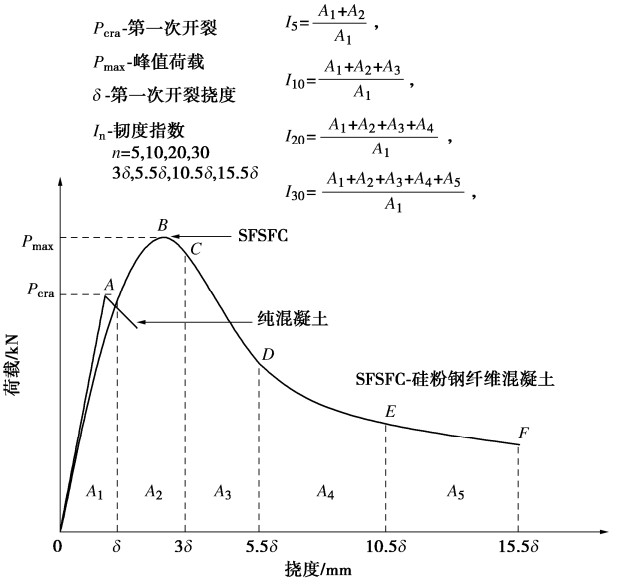

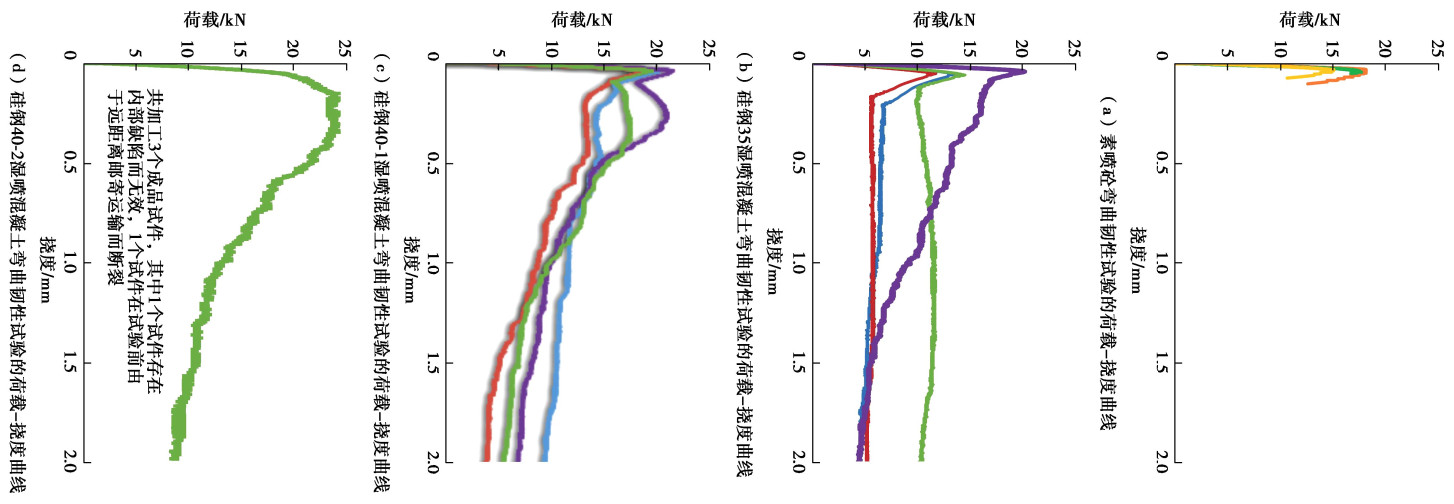

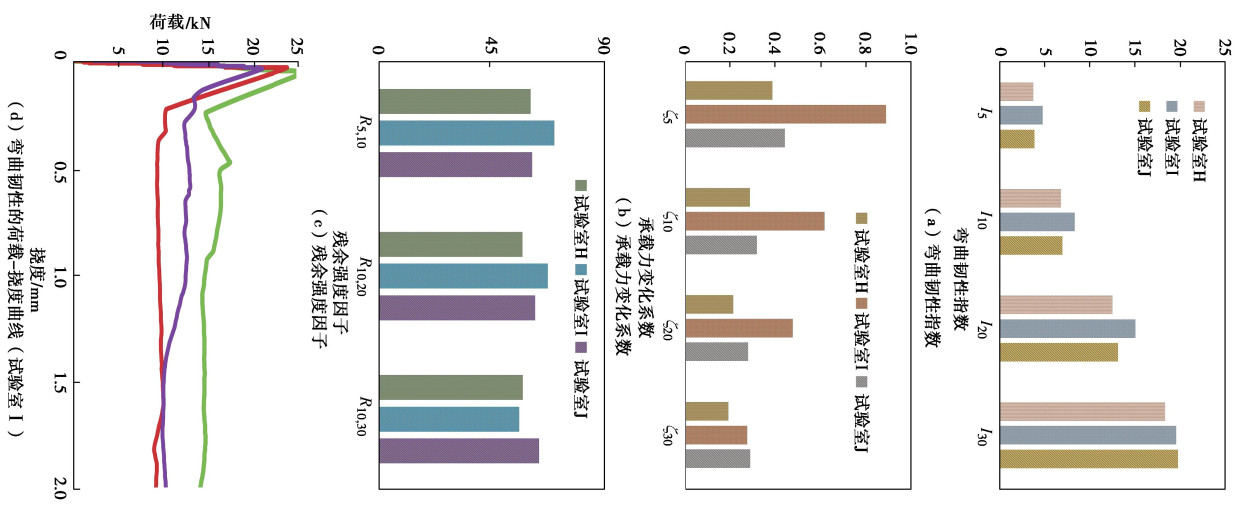

摘要: 针对强岩爆、高突涌水、高地应力硐室,采用弓形排状新型钢纤维、新型液态无碱速凝剂、大型湿喷台车+机械臂及钢纤维新型添加工艺系统开展了掺硅粉及钢纤维湿喷混凝土的现场弯曲韧性试验研究。这种能够真实反应湿喷混凝土现场附着硬化性能的大规模生产性试验研究在中国尚属首次。结果表明:随着硅粉和钢纤维的掺入,附着硬化后的湿喷混凝土初裂荷载和极限荷载提高,弯曲韧性指数、承载能力变化系数及残余强度因子明显改善,开裂后未发生脆性断裂,峰值荷载后的承载力下降缓慢,且作用效果随着纤维掺量的增加而增强,其中40 kg掺量下荷载-挠度曲线有二次硬化现象,材料去脆性化迹象明显,抑制围岩破坏和与围岩同步变形能力得到增强。Abstract: For the cavern with of rockburst, water gushing and high geostress, the researches on the on-site flexural toughness properties of the wet-sprayed concrete containing silica fume (SF) and reinforced by steel fibers are carried out to investigate the effects of steel fiber content and SF on flexural toughness index and the difference from the plain concrete. The SF is added according to 10% of the cement mass, two mass contents of steel fiber (35, 40 kg/m3) are considered in this study, and large wet spraying machine is used. The concrete specimens used in the flexural toughness experiments are formed in site, which contain accelerator of 8%. It is the first time in China that the large-scale productive experiments adopt a large number of new technologies and can truly reflect the on-site adhesion and hardening properties of the wet sprayed concrete. Through the collaborative participation of 10 institutions, the experiments are successfully completed, and the effective results are achieved. It is indicated that the crack load and the ultimate load of concrete increased, the flexural toughness is improved when the SF and steel fiber are added, and the flexural toughness index increases with the increment of the steel fiber. Especially, the load-deflection curves show the peak of the secondary hardening of shotcrete with steel fiber content of 40 kg, which means the better resistance deformation capacity and increased residual strength. So the steel fiber reinforced wet-sprayed concrete containing the SF can enhance its toughness and the capability of resisting crack and improve its brittleness characteristic.

-

0. 引言

传统的以混凝土为主要建筑材料的基坑支护技术,存在资源利用效率低、污染环境及支护结构遗留地下对后续工程造成障碍等问题。装配式、可回收技术符合国家绿色节能、低碳环保的发展理念,是基坑支护技术发展的重要方向[1-2]。支挡式结构是目前软土基坑支护的主要型式,早期可回收技术的研究主要针对单一结构构件,如可回收锚杆、型钢支撑等支锚构件和组合型钢等挡土构件[3-6],并通过模型和现场试验总结了相关可回收构件的受力变形规律[7-8]。在此基础上,可回收技术也逐渐实现从单一构件向空间体系的发展。随着全回收基坑支护的概念日益突出,中国工程建设标准化协会发布了《全回收基坑支护技术规程》,国内也陆续出台了相关地方标准,持续构建基坑支护技术的新发展格局和实践方向。

本文研发了一种适用于软土的钢管锚锭板桩全回收基坑支护技术,并利用模型试验研究技术参数对基坑支护体系稳定性的影响,为构建其设计方法提供科学依据。

1. 钢管锚锭板桩全回收基坑支护技术

钢管锚锭板桩全回收基坑支护体系由钢板桩、钢管桩、钢拉杆和钢腰梁等组成,如图 1所示,所有构件在基坑回填后均可实现回收。

钢板桩采用带有锁口的帽形型钢,锁口可以相互组合形成连续紧密的钢结构墙体(图 2(a));钢管桩作为锚锭构件,采用大直径圆形钢管(图 2(b));钢拉杆作为钢板桩和钢管桩之间的受力连接构件,与钢管桩一一对应;钢拉杆采用中空锚杆(图 2(c)),两端为螺纹锚头,利用螺母分别与钢板桩和钢管桩连接;钢腰梁作为钢拉杆与钢板桩之间的传力构件,可调节钢板桩均匀受力,采用双拼H型钢(图 2(d))。

2. 支护体系稳定性模型试验

影响支护体系稳定性的因素除土体性质外,主要有管桩与板桩的间距、管桩的规格(长度、刚度、间距等)、板桩的规格(长度、刚度等)。因篇幅所限,本文主要探讨管桩与板桩的不同间距对支护结构变形的影响。

2.1 试验用土

模型试验用土取自青岛市上合示范核心区的海相软土,天然密度平均值为1.85 g/cm3,含水率平均值为34.5%,塑限和液限的平均值分别为16.6%和32.4%,塑性指数为15.8,属于淤泥质粉质黏土。

2.2 模型构件

模型板桩和管桩材料选用尼龙板和尼龙管,按相似理论确定模型尺寸。本试验以拉森Ⅳ型钢板桩和外径1 m、壁厚25 mm的钢管桩为原型,原型与模型的长度相似比为10。试验主要研究管桩和板桩受力后的弯曲变形及位移特点,因而考虑模型与原型的抗弯刚度(EI)相匹配。尼龙的重度γm=11.5 kN/m3,弹性模量Em=2.83 GPa,计算得模型板桩的厚度hm为17.0 mm,模型管桩的直径Dm=100 mm,壁厚tm为2.7 mm。拉杆采用直径4 mm的不锈钢棒,两端分别与尼龙板和尼龙管栓接。

2.3 试验装置

试验装置包括模型箱、加载系统及监测系统3部分组成。模型箱体内部净尺寸长3 m,宽1 m,高1.5 m。加载系统由气缸、加载板、反力架和空气压缩机组成(图 3)。

监测系统包括埋设模型地基内的孔隙水压力传感器、加载板位移传感器、微型薄膜土压力计,以及数字图像相关系统(简称DIC系统)和摄影测量分析设备(简称DPA设备)(图 4)。

2.4 试验方案

管桩与板桩的间距L如表 1所示。采用单根管桩时,管桩设置于模型箱的长轴中心线上;采用两根管桩时,管桩间距为300 mm,在模型箱的长轴中心线两侧对称布置。在满足试验边界条件的前提下,为减少试验工作量,同一个模型地基,在模型箱两端各实施一个基坑开挖试验,即A1与A4、A2与A3、B1与B2为同一个模型地基,试验布置如图 5和图 6。

表 1 试验方案Table 1. Test schemes试验编号 单管 双管 A1 A2 A3 A4 B1 B2 管桩与板桩间距L/mm 100 300 500 1000 300 500 2.5 模型地基

(1)模型地基制作方法

模型地基采用逐级加载固结的方式制作,前一级荷载作用下土体固结完成后施加下一级荷载。土体固结完成的判别标准是土体竖向变形速率小于2 mm/d且超静孔隙水压力基本消散。以原状土的天然密度(1.85 g/cm3)为目标值,通过预备试验确定首级荷载2 kPa、之后每级增加10 kPa至最终荷载70 kPa。

(2)模型地基土的物理力学性质

开挖试验结束后,在两个试验区交界附近,分别从模型地基深度20,50,90 cm处取样,进行密度、含水率、直接剪切和三轴不固结不排水剪切等试验。

模型地基土的平均密度自上而下呈略微增大趋势,分别为1.84,1.86,1.87 g/cm3;平均含水率自上而下呈“C”字型规律分布,即上、下部排水条件较好,含水率略低于中部,中部含水率平均值(32.9%)在数值上与原状土的液限(32.4%)和天然含水率(34.5%)相近。

模型地基土的各组平均抗剪强度指标,黏聚力cq为3.0~4.8 kPa、cUU为5.5~6.2kPa;内摩擦角φq为5.6~6.0°、φUU为2.3~3.9°。抗剪强度指标变异系数较小,均匀性较好,且与原状土试验指标接近。

2.6 基坑开挖试验方法

模型地基制作完成后,在预定的开挖区分层进行人工开挖,每层开挖深度为10 cm,直至基坑顶面发生明显变形、开裂破坏,或开挖深度达到50 cm。

3. 试验结果与分析

3.1 破坏型式

各组试验得到的基坑顶面破坏型式类似,A4和B2组试验的破坏情况见图 7。对A组(单管桩)试验,当两者间距为10 cm时,虽地表未出现贯通滑裂面,但板桩和管桩均发生明显变形,滑裂面位于管桩外侧;当间距增加为30 cm和50 cm时,在管桩附近地表出现贯通性滑裂线,表明桩间土形成局部塑性区并发展成贯通滑裂面;当间距增加至100 cm时,地表贯通性滑裂面出现在板桩与管桩之间,距离板桩约70~80 cm,与板桩后的朗肯主动土压力区宽度基本一致。对B组(双管桩)试验,其整体破坏规律与A组试验中管桩与板桩具有相同间距的试验结果相似。

3.2 土压力的变化规律

图 8给出了A1和B1组试验中作用在板桩上的土压力变化规律。深度0.3 m处的两个土压力计监测的土压力值基本一致,初始土压力值与朗肯土压力计算的静止土压力值基本一致,土压力值随着开挖深度的增加而减小,对应从开挖前静止土压力到开挖后主动土压力的转变。深度0.7 m位于开挖深度范围下,初始土压力值亦与静止土压力计算值接近,土压力值则随着开挖深度的增加而增加,主要与板桩刚度较小、沿竖向反弯变形挤压土体有关。

3.3 管桩水平位移的变化规律

桩顶位移随开挖深度的增加而逐渐增大,当开挖深度较小时接近线性变化,在水平位移突变后仍有一定承载和抗变形能力,总体符合双曲线变化规律,拟合优度系数R2均大于0.9(如图 9)。双曲线拟合式中位于分子的拟合参数反映了极限开挖深度,而位于分母的拟合参数则反映了双曲线趋于渐近线的速率。试验结果显示,A1和A4组的极限开挖深度基本一致,A2和A3组基本一致,而B1和B2组(双管桩)的极限开挖深度基本一致且大于管桩和板桩间距相同条件下A2和A3组(单管桩)的结果,表明极限开挖深度和管桩与板桩间距有关,当管桩与板桩间距超过某范围时,两者间距越大,同等开挖深度条件下支护体系变形越小。此外,极限开挖深度与管桩间距成反比,管桩间距越小,同等条件下极限开挖深度越大。同时,对管桩顶部水平位移的监测数据表明,当土体发生较大变形至破坏时,管桩发生整体倾斜。

3.4 板桩水平位移的变化规律

图 10给出了利用DPA设备获得的A1和B1组试验中的板桩顶部水平位移。板桩顶部的水平位移随开挖深度的增加而逐渐增大,在水平方向上,由于管桩的锚锭作用,对A组(单管桩),其值以拉杆位置为对称轴,左右近似对称分布,与拉杆距离越远位移越大,呈“V”型分布且随开挖深度增加而愈加明显。对B组(双管桩),其值以两根拉杆的中心线为对称轴,左右近似对称分布。同时,B组的桩顶位移明显小于A组,管桩间距直接影响作用在板桩上的土压力,且整体刚度的增加也有利于位移控制。

3.5 管桩与板桩的变形协调

将各组试验中管桩与板桩的桩顶(拉杆处)水平位移汇总比较,如图 11所示,计算管桩与板桩水平位移的相关系数r为0.96,属显著性相关。

各组试验中管桩与板桩的变形虽然受开挖深度、施工工序等影响,但通过拉杆作用,拉杆两端的实测位移总体相差较小,两者变形具有一致性。因此,在设计中可通过增加拉杆刚度,减小两者之间的变形差。

4. 结论

(1)管桩的锚拉对结构位移具有显著限制作用。管桩顶部最大水平位移与开挖深度成双曲线关系。双管桩条件下的板桩位移明显小于单管桩条件下的结果,即增加板桩单位宽度内的管桩数量可以有效减小支护体系的位移。

(2)模型地基的变形破坏形式与管桩至板桩的间距有关。两者间距较近时,主动滑裂面的发展受到管桩限制,沿管桩位置滑裂。两者间距足够远时,滑裂面沿与板桩距离开挖深度约1.5倍的地表滑裂。

(3)管桩与板桩顶部的位移总体相差较小,两者的变形具有一致性。设计中可将两者的变形协调做为假定条件,以求解杆件体系力学平衡微分方程。

-

表 1 速凝剂品质检测结果

Table 1 Physical and chemical properties of accelerator

掺量/% 掺速凝剂净浆凝结时/min 掺速凝剂砂浆 含固量/% 碱含量/% pH值 相对质量密度 初凝 终凝 1 d抗压强度/MPa 28 d抗压强度比/% 8 2︰08 3︰16 10.0 89 38.9 3.52 2.45 1.41 表 2 硅粉物理化学性能检测结果

Table 2 Physical and chemical properties of silica fume

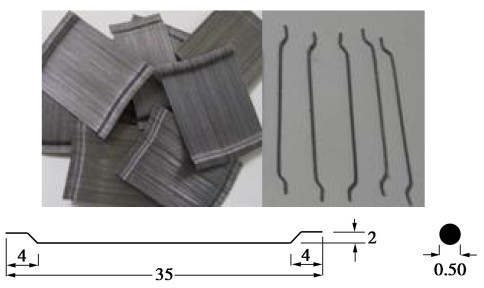

需水量比/% 28 d活性指数/% 细度/% 比表面积/(m2·kg-1) 含水率/% 堆积密度/(kg·m-3) 碱含量/% SiO2/% Loss/% Cl—/% 120 97.6 0.05 15000 0.46 250 1.23 93.2 1.15 0.012 表 3 钢纤维DramixRC-65/35-BN)物理性能试验结果

Table 3 Performance parameters of Dramix steel fiber

检验项目 组数 平均长度L/mm 平均直径d/mm 平均长径比L/d 平均截面积/mm2 抗拉强度/MPa 弯曲性能 平均值 最小值 检验结果 10 35.88 0.55 65 0.24 1240 1024 无断裂 表 4 试验用湿喷混凝土配合比参数

Table 4 Mix proportions of wet-sprayed concrete mixtures

配比序号 水胶比 减水剂掺量/% 硅粉/% 砂率/% 设计坍落度/mm 单方混凝土各材料用量/(kg·m-3) 浆集比 砂石比 用水量 水泥 硅粉 人工砂 米石 钢纤维 减水剂 速凝剂 素喷砼 0.48 1 — 60 160~180 218 454 — 982 654 — 4.54 31.78 0.28 1.50 硅钢35 0.45 1 10 60 160~180 227 454 51 970 653 35 5.05 35.35 0.30 1.49 硅钢40-1 1 10 60 160~180 227 454 51 970 653 40 5.05 35.35 0.30 1.49 硅钢40-2 0.44 0.8 9 65 160~180 230 479 47.9 1084 571 40 3.832 36.88 0.31 1.90 注:浆集比计算时钢纤维量计入骨料。 表 5 弯曲韧性指数汇总表

Table 5 Flexural toughness indices

配比序号 I5 I10 I20 I30 素喷砼 1 1 1 1 硅钢35 3.82 6.77 12.27 17.62 硅钢40-1 3.96 7.18 13.61 19.45 硅钢40-2 4.58 9.51 18.86 26.05 表 6 混凝土弯曲强度及挠度试验结果

Table 6 Test results of bending strength and deflection of concrete

配比序号 初裂荷载/kN 初裂挠度/mm 初裂抗弯强度/MPa 极限荷载/kN 最大挠度/mm 极限抗弯强度/MPa 素喷砼 14.3659 0.032 4.311 14.7695 0.042 4.431 硅钢35 19.9037 0.040 5.971 20.1507 3.045 6.045 硅钢40-1 21.2758 0.040 6.383 21.5621 3.093 6.469 硅钢40-2 19.1570 0.054 5.750 24.252 2.028 7.276 表 7 承载能力变化系数汇总表

Table 7 Variation coefficients of load-carrying capability

配比序号 ζ5 ζ10 ζ20 ζ30 素喷砼 — — — — 硅钢35 0.41 0.28 0.19 0.15 硅钢40-1 0.48 0.37 0.33 0.27 硅钢40-2 0.79 0.89 0.88 0.73 表 8 残余强度试验结果

Table 8 Test results of residual strength factors

配比序号 R5, 10 R10, 20 R10, 30 素喷砼 — — — 硅钢35 59.00 55.00 54.25 硅钢40-1 64.20 64.30 61.35 硅钢40-2 98.60 93.47 82.67 -

[1] Guide for the Use of Silica Fume in Concrete: ACI 234R-06 [S]. 2012.

[2] WAN Z M, HE T S, CHANG N, et al. Effect of silica fume on shrinkage of cement-based materials mixed with alkali accelerator and alkali-free accelerator[J]. Journal of Materials Research and Technology, 2023, 22: 825-837. doi: 10.1016/j.jmrt.2022.11.110

[3] CHOI P, YEON J H, YUN K K. Air-void structure, strength, and permeability of wet-mix shotcrete before and after shotcreting operation: the influences of silica fume and air-entraining agent[J]. Cement and Concrete Composites, 2016, 70: 69-77. doi: 10.1016/j.cemconcomp.2016.03.012

[4] LOTHENBACH B, RENTSCH D, WIELAND E. Hydration of a silica fume blended low-alkali shotcrete cement[J]. Physics and Chemistry Earth, Parts A/B/C, 2014, 70/71: 3-16. doi: 10.1016/j.pce.2013.09.007

[5] AUSTIN S A, ROBINS P J, PEASTON C H. Effects of silica fume on dry-process sprayed concrete[J]. Magazine of Concrete Research, 1998, 50(1): 25-36. doi: 10.1680/macr.1998.50.1.25

[6] YUN K K, CHOI S Y, YEON J H. Effects of admixtures on the rheological properties of high-performance wet-mix shotcrete mixtures[J]. Construction and Building Materials, 2015, 78: 194-202. doi: 10.1016/j.conbuildmat.2014.12.117

[7] NING F W, CAI Y B, BAI Y, et al. Effect of expansive agent and internal curing agent on crack resistance of C50 silica fume wet-mix shotcrete[J]. Advances in Mechanical Engineering, 2019, 11(1): 1-11.

[8] SJÖLANDER A, ANSELL A, NORDSTRÖM E. On the design of permanent rock support using fibre-reinforced shotcrete[J]. Fibers, 2023, 11(2): 20. doi: 10.3390/fib11020020

[9] GULER S, ÖKER B, AKBULUT Z F. Workability, strength and toughness properties of different types of fiber-reinforced wet-mix shotcrete[J]. Structures, 2021, 31: 781-791. doi: 10.1016/j.istruc.2021.02.031

[10] CONGRO M, MOREIRA DE ALENCAR MONTEIRO V, DE ANDRADE SILVA F, et al. A novel hybrid model to design fiber-reinforced shotcrete for tunnel linings[J]. Tunnelling and Underground Space Technology, 2023, 132: 104881. doi: 10.1016/j.tust.2022.104881

[11] ALI SHAH S A, ALI GUL M A, NAQASH T, et al. Effects of fiber reinforcements on the strength of shotcrete[J]. Civil Engineering and Architecture, 2021, 9(1): 176-183. doi: 10.13189/cea.2021.090115

[12] ANSELL A. Tomography based method for investigation of steel fibre distribution in tunnel shotcrete[M]// Expanding Underground-Knowledge and Passion to Make a Positive Impact on the World. London: CRC Press, 2023: 435-443.

[13] ESTRADA CÁCERES A R, CAVALARO S H P, MONTE R, et al. Alternative small-scale tests to characterize the structural behaviour of steel fibre-reinforced sprayed concrete[J]. Construction and Building Materials, 2021, 296: 123168. doi: 10.1016/j.conbuildmat.2021.123168

[14] ARMELIN H S, HELENE P. Physical and mechanical properties of steel-fiber reinforced dry-mix shotcrete[J]. ACI Materials Journal, 1995, 92(3): 258-267.

[15] MORGAN D R, MCASKILL N, RICHARDSON B W, et al. A Comparative Evaluation of Plain, Polypropylene Fiber, Steel Fiber, and Wire Mesh Reinforced Shotcretes. International Symposium on Recent Developments in Concrete Fiber Composites[R]. Washington D: Transportation Research Board, 1989.

[16] AUSTIN S A, PEASTON C H, ROBINS P J. Material and fibre losses with fibre reinforced sprayed concrete[J]. Construction and Building Materials, 1997, 11(5/6): 291-298.

[17] Bindiganaville, Vivek Srinivasan. High-reactivity Metakaolin and Silica Fume in Steel Fiber Reinforced Dry-mix Shotcrete[M]. Vancouver: University of British Columbia, 1998.

[18] YAN X, LIU L M, ZHANG J P, et al. Experimental study on basic mechanical properties of steel fiber-reinforced siliceous wet shotcrete[J]. Advances in Materials Science and Engineering, 2018(1): 8.

[19] ESTRADA CÁCERES A R, CAVALARO S H P, MONTE R, et al. Alternative small-scale tests to characterize the structural behaviour of steel fibre-reinforced sprayed concrete[J]. Construction and Building Materials, 2021, 296: 123168. doi: 10.1016/j.conbuildmat.2021.123168

[20] CHOI P, YUN K K, YEON J H. Effects of mineral admixtures and steel fiber on rheology, strength, and chloride ion penetration resistance characteristics of wet-mix shotcrete mixtures containing crushed aggregates[J]. Construction and Building Materials, 2017, 142: 376-384. doi: 10.1016/j.conbuildmat.2017.03.093

[21] MORGAN D R, KIRKNESS A J, MCASKILL N, et al. Freeze-thaw durability of wet-mix and dry-mix shotcretes with silica fume and steel fibres[J]. Cement, Concrete, and Aggregates, 1988, 10(2): 96-102. doi: 10.1520/CCA10089J

[22] LEUNG C K Y, LAI R, LEE A Y F. Properties of wet-mixed fiber reinforced shotcrete and fiber reinforced concrete with similar composition[J]. Cement and Concrete Research, 2005, 35(4): 788-795. doi: 10.1016/j.cemconres.2004.05.033

[23] LI F H, CHENG Y H, WU F, et al. Compressive test characteristics and constitutive relationship of wet polypropylene macrofiber-reinforced shotcrete[J]. Shock and Vibration, 2021, 2021(1): 6649283. doi: 10.1155/2021/6649283

[24] YAN X, LIU L M, ZHANG J P, et al. Experimental study on basic mechanical properties of steel fiber-reinforced siliceous wet shotcrete[J]. Advances in Materials Science and Engineering, 2018(1): 1-8.

[25] CÁCERES A R E, CAVALARO S H P, DE FIGUEIREDO A D. Integrated approach for quality control of fibre-reinforced sprayed concrete for tunnel lining[J]. Tunnelling and Underground Space Technology, 2023, 140: 105260. doi: 10.1016/j.tust.2023.105260

[26] KAUFMANN J, FRECH K, SCHUETZ P, et al. Rebound and orientation of fibers in wet sprayed concrete applications[J]. Construction and Building Materials, 2013, 49: 15-22. doi: 10.1016/j.conbuildmat.2013.07.051

[27] WANG Xiongxin. Understanding the Placement Mechanism of Wet-Mix Shotcrete and the Influence of Material[D]. Florida: Florida State University, 2021.

[28] 王家滨, 牛荻涛, 张永利. 喷射混凝土力学性能、渗透性及耐久性试验研究[J]. 土木工程学报, 2016, 49(5): 96-109. WANG Jiabin, NIU Ditao, ZHANG Yongli. Investigation of mechanical, permeability and durability performance of shotcrete with and without steel fiber[J]. China Civil Engineering Journal, 2016, 49(5): 96-109. (in Chinese)

[29] 夏冬桃, 张周强, 张严方, 等. 混杂纤维喷射混凝土的弯曲韧性[J]. 土木建筑与环境工程, 2015(2): 67-72. XIA Dongtao, ZHANG Zhouqiang, ZHANG Yanfang, et al. Flexural toughness of hybrid fiber reinforced shotcrete[J]. Journal of Civil, Architectural & Environment Engineering, 2015(2): 67-72. (in Chinese)

[30] 苏安双, 宁逢伟, 韩旭东, 等. 含水率及加载速率对纤维增韧喷射混凝土弯曲韧性的影响[J]. 水利水运工程学报, 2013(5): 46-53. doi: 10.3969/j.issn.1009-640X.2013.05.007 SU Anshuang, NING Fengwei, HAN Xudong, et al. Influences of moisture content and loading rate on flexural toughness of fiber reinforced shotcrete[J]. Hydro-Science and Engineering, 2013(5): 46-53. (in Chinese) doi: 10.3969/j.issn.1009-640X.2013.05.007

[31] LI Chuanxi, NIE Jie, SHI Jiakuan, et al. Effect of fiber type on compressive strength and flexural toughness of concrete and analysis of variability[J]. Journal of Civil, Architectural & Environmental Engineering, 2019, 41(2): 147-158. (in Chinese) [32] 史占崇, 苏庆田, 邵长宇, 等. 粗骨料UHPC的基本力学性能及弯曲韧性评价方法[J]. 土木工程学报, 2020, 53(12): 86-97. SHI Zhanchong, SU Qingtian, SHAO Changyu, et al. Basic mechanical behavior and flexural toughness evaluation method of coarse aggregate UHPC[J]. China Civil Engineering Journal, 2020, 53(12): 86-97. (in Chinese)

[33] JENG F, LIN M L, YUAN S C. Performance of toughness indices for steel fiber reinforced shotcrete[J]. Tunnelling and Underground Space Technology, 2002, 17(1): 69-82. doi: 10.1016/S0886-7798(01)00065-7

[34] 高尔新, 李元生, 薛玉, 等. 喷射混凝土钢纤维分布特性分析[J]. 岩土工程学报, 2002, 24(2): 202-203. doi: 10.3321/j.issn:1000-4548.2002.02.016 GAO Erxin, LI Yuansheng, XUE Yu, et al. Analysis on distributions of steel-fiber in reinforced shotcrete[J]. Chinese Journal of Geotechnical Engineering, 2002, 24(2): 202-203. (in Chinese) doi: 10.3321/j.issn:1000-4548.2002.02.016

[35] AUSTIN S A, PEASTON C H, ROBINS P J. Material and fibre losses with fibre reinforced sprayed concrete[J]. Construction and Building Materials, 1997, 11(5/6): 291-298.

[36] NICOLAS G, MARC J. Characterization of placement phenomenon in wet sprayed concrete[C]// 7th International symposium on sprayed concrete-Modern Use of Wet Mix Sprayed Concrete for Underground Support-Sandefjord, Norway, 2014.

[37] GINOUSE N, JOLIN M, BISSONNETTE B. Effect of equipment on spray velocity distribution in shotcrete applications[J]. Construction and Building Materials, 2014, 70: 362-369. doi: 10.1016/j.conbuildmat.2014.07.116

[38] 国家能源局. 水工喷射混凝土试验规程: DL/T 5721—2015[S]. 北京: 中国电力出版社, 2015. National Energy Bureau of the People's Republic of China. Test code for hydraulic shotcrete: DL/T 5721—2015[S]. Beijing: China Electric Power Press, 2015. (in Chinese)

[39] 丁一宁, 董香军, 王岳华. 钢纤维混凝土弯曲韧性测试方法与评价标准[J]. 建筑材料学报, 2005, 8(6): 660-664. doi: 10.3969/j.issn.1007-9629.2005.06.013 DING Yining, DONG Xiangjun, WANG Yuehua. Testing methods and evaluating standards of flexural toughness for steel fiber reinforced concrete[J]. Journal of Building Materials, 2005, 8(6): 660-664. (in Chinese) doi: 10.3969/j.issn.1007-9629.2005.06.013

[40] 卫明山, 李利莎, 郑全平, 等. 钢纤维混凝土韧性指数评价方法对比研究[J]. 建筑结构, 2007, 37(12): 90-92. WEI Mingshan, LI Lisha, ZHENG Quanping, et al. Comparative study of evaluate method for toughness factor of steel fiber reinforced concrete(SFRC)[J]. Building Structure, 2007, 37(12): 90-92. (in Chinese)

[41] 高丹盈, 赵亮平, 冯虎, 等. 钢纤维混凝土弯曲韧性及其评价方法[J]. 建筑材料学报, 2014, 17(5): 783-789. doi: 10.3969/j.issn.1007-9629.2014.05.006 GAO Danying, ZHAO Liangping, FENG Hu, et al. Flexural toughness and it's evaluation method of steel fiber reinforced concrete[J]. Journal of Building Materials, 2014, 17(5): 783-789. (in Chinese) doi: 10.3969/j.issn.1007-9629.2014.05.006

[42] Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading): ASTM C1018-97 [S]. 1997.

[43] SINGH S P, SINGH A P, BAJAJ V. Strength and flexural toughness of concrete reinforced with steel - polypropylene hybrid fibres[J]. Asian Journal of Civil Engineering, 2010, 11(4): 495-507.

[44] 赖建中, 孙伟, 董贺祥. 粗合成纤维混凝土力学性能及纤维-混凝土界面黏结行为研究[J]. 工业建筑, 2006, 36(11): 94-97. LAI Jianzhong, SUN Wei, DONG Hexiang. Mechanical performance of synthetic structural fiber reinforced concrete and bond behaviour of fiber-matrix interface[J]. Industrial Construction, 2006, 36(11): 94-97. (in Chinese)

下载:

下载: