Thermo-mechanical coupling characteristics of single energy pile operation in 2×2 pile-cap foundation

-

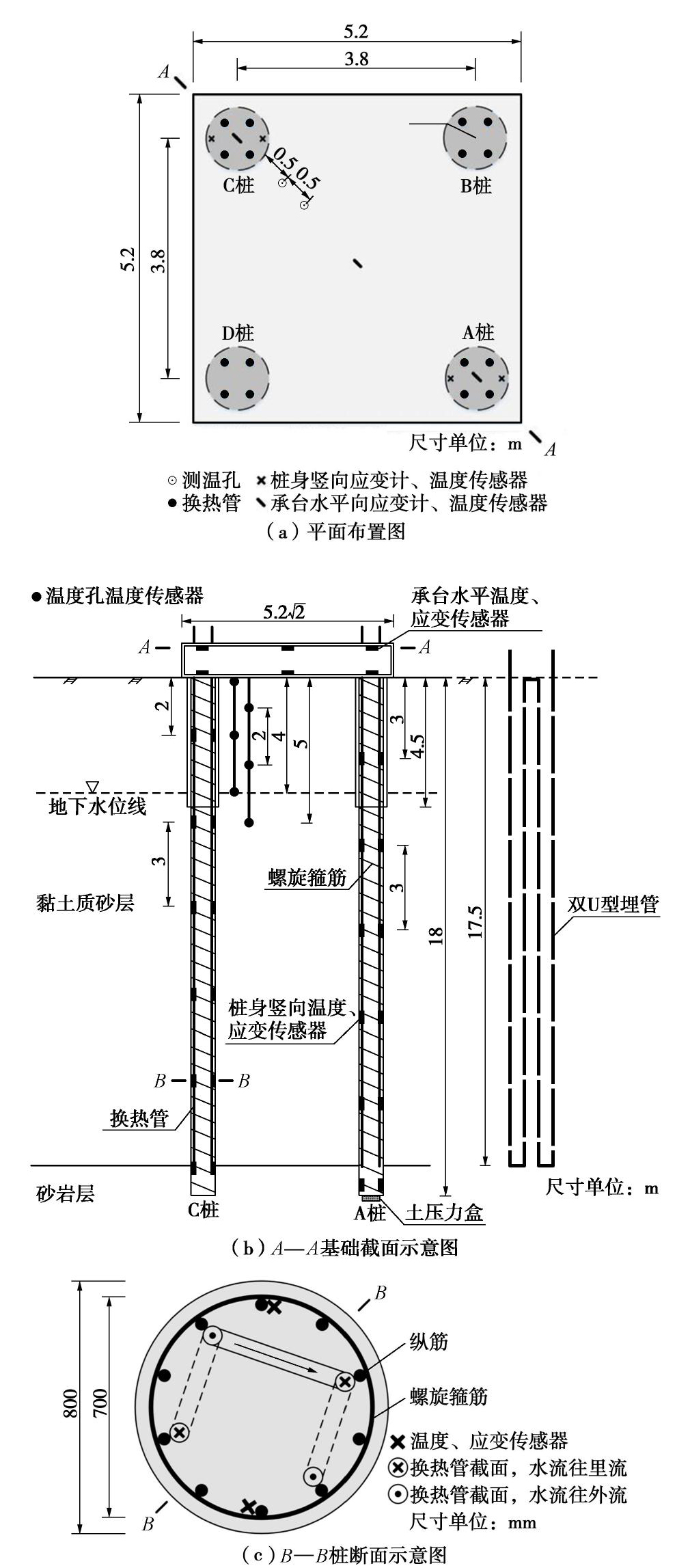

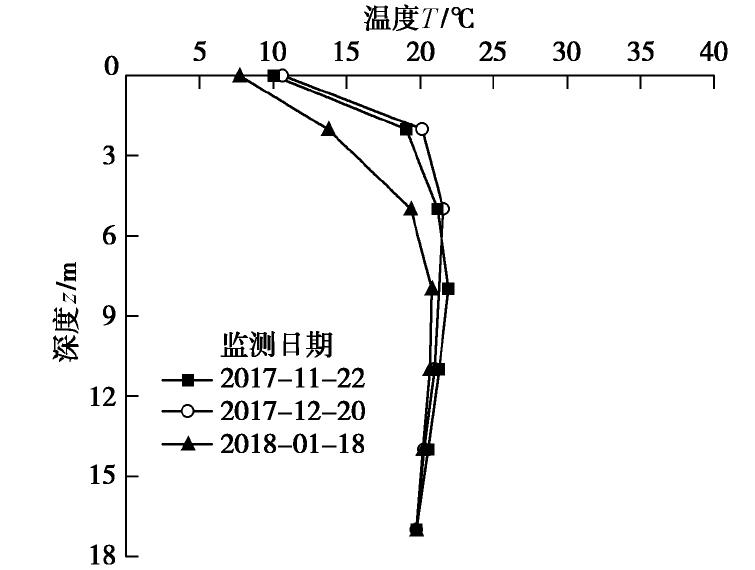

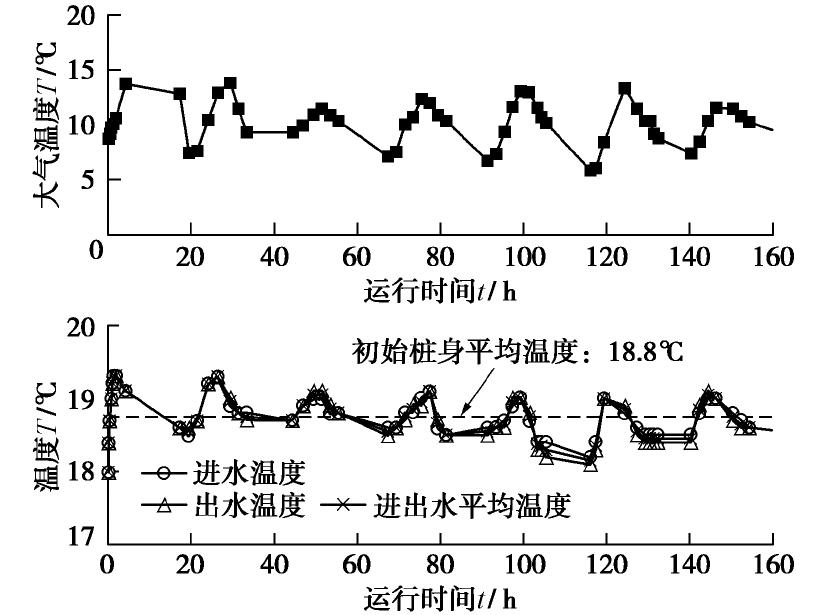

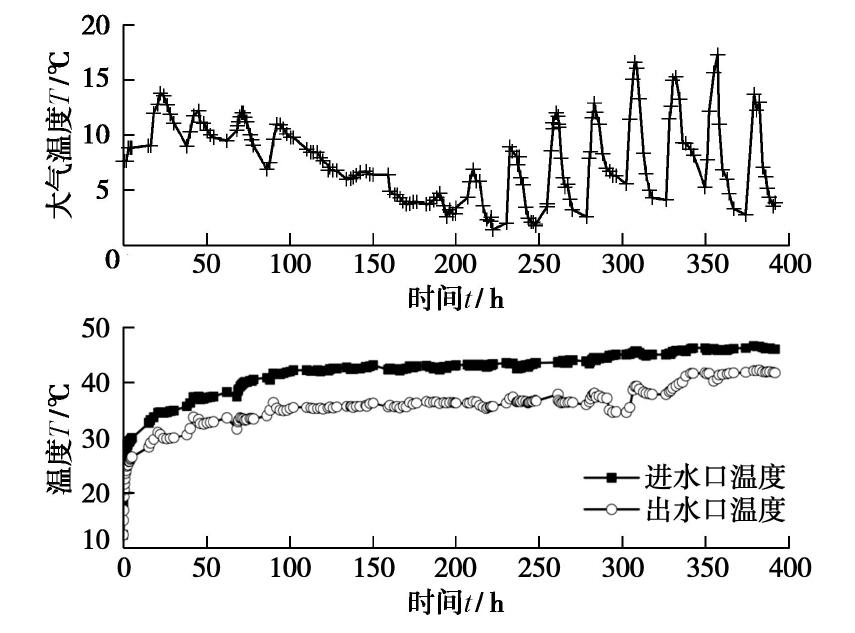

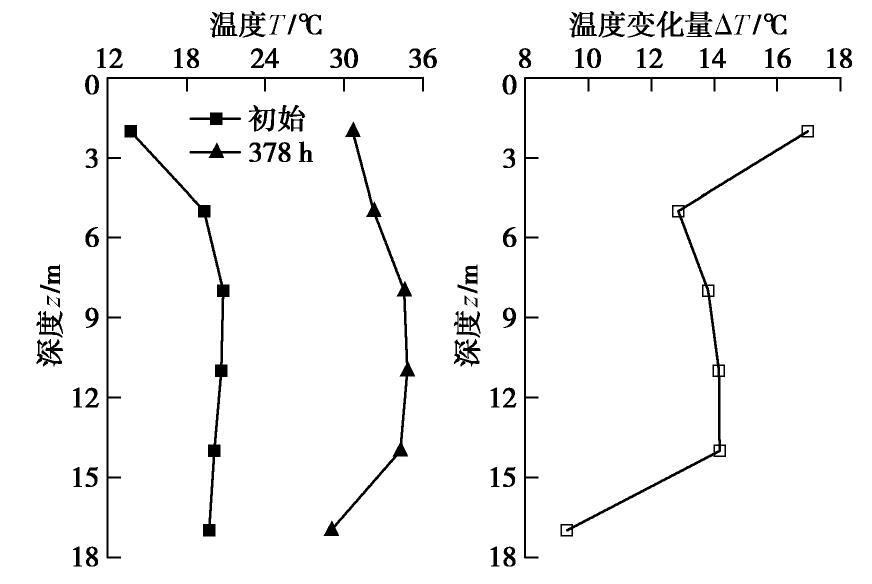

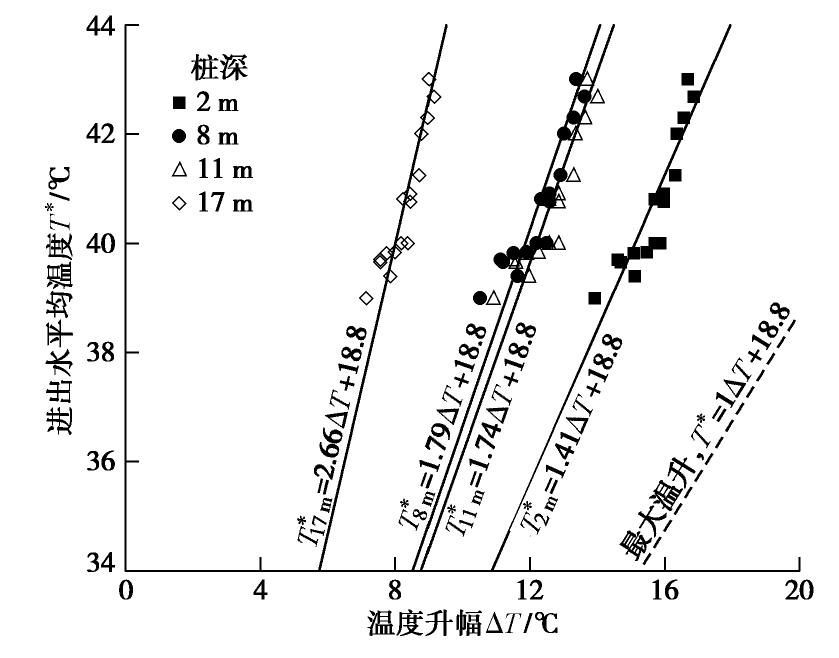

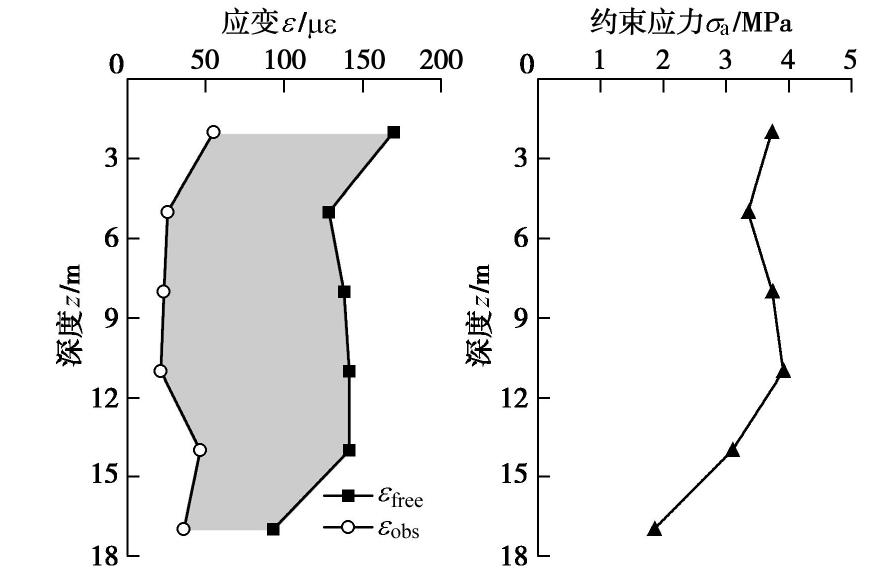

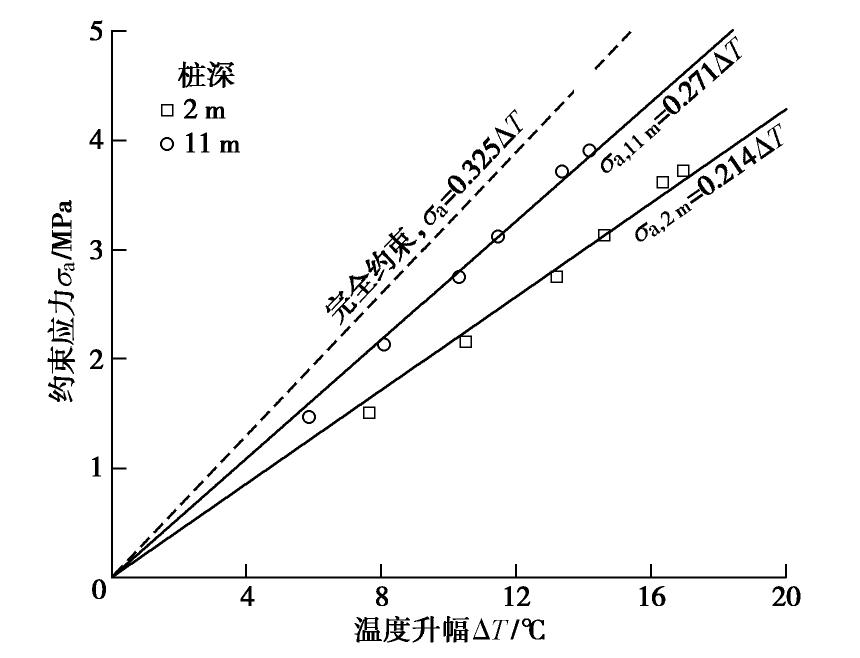

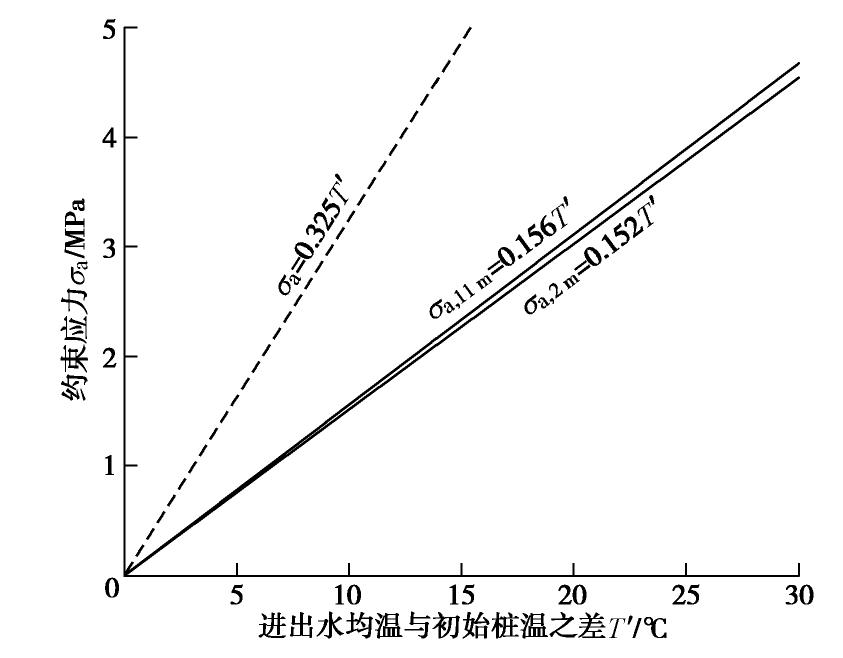

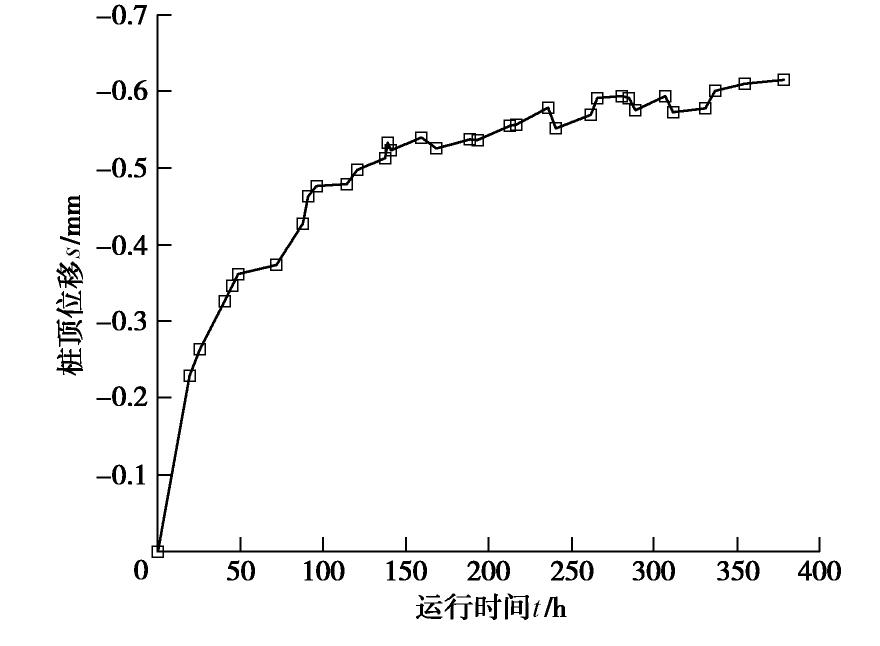

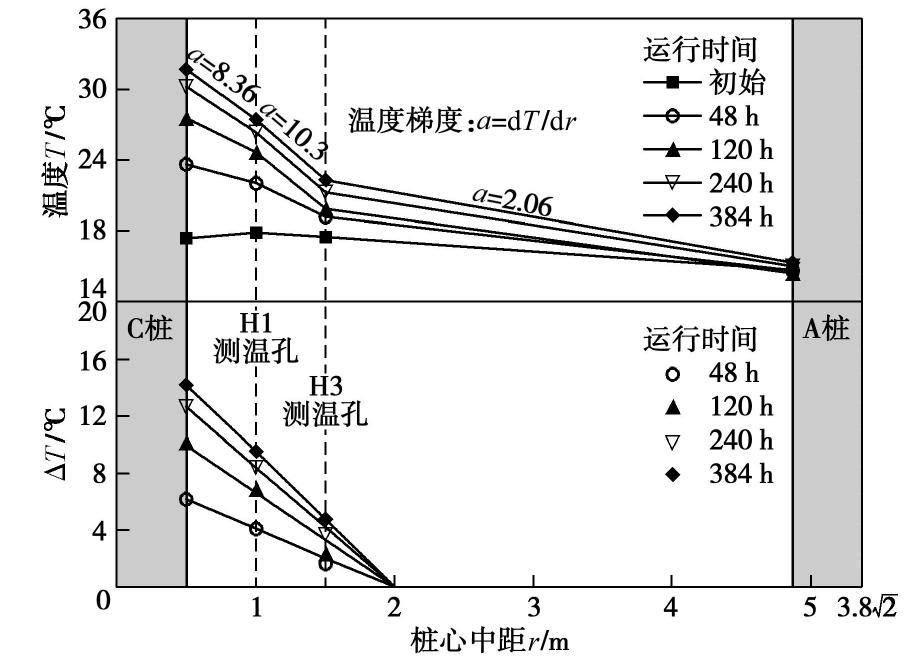

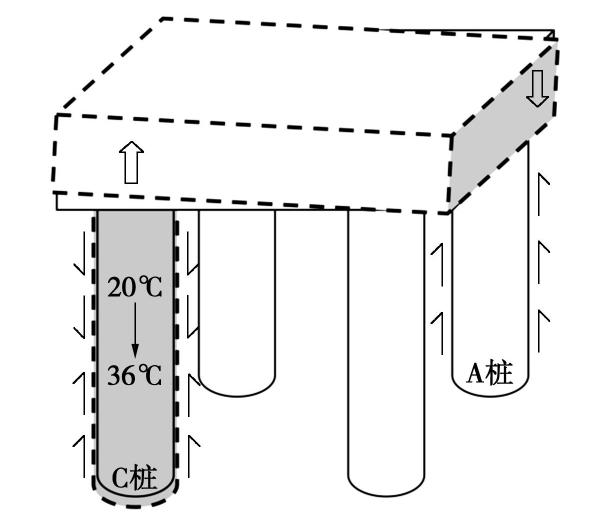

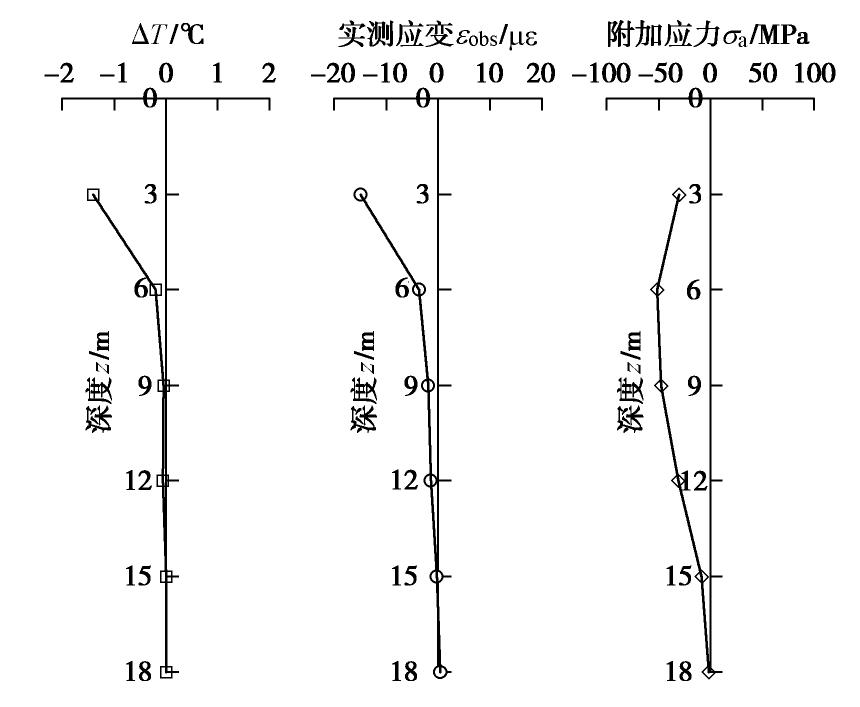

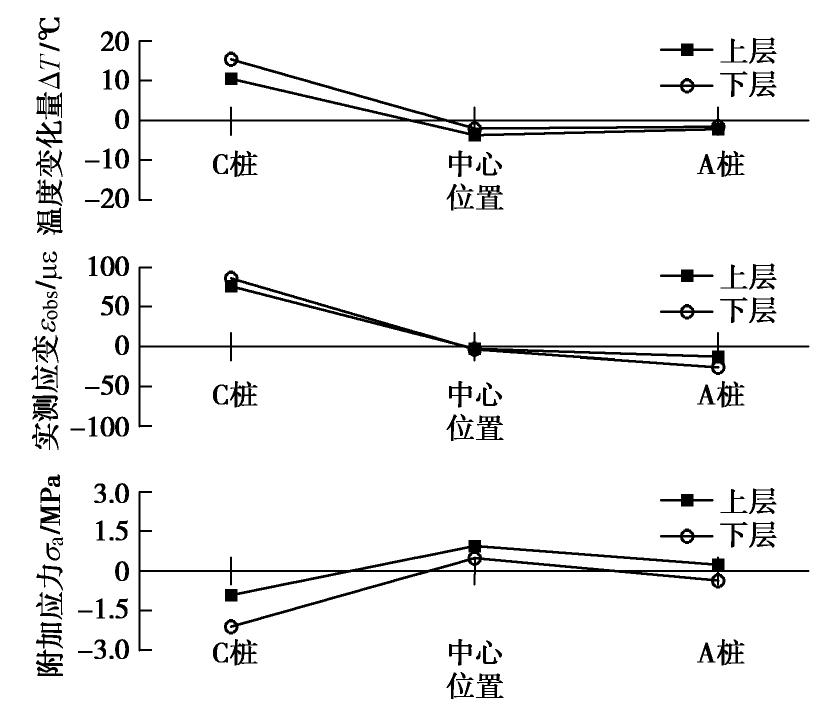

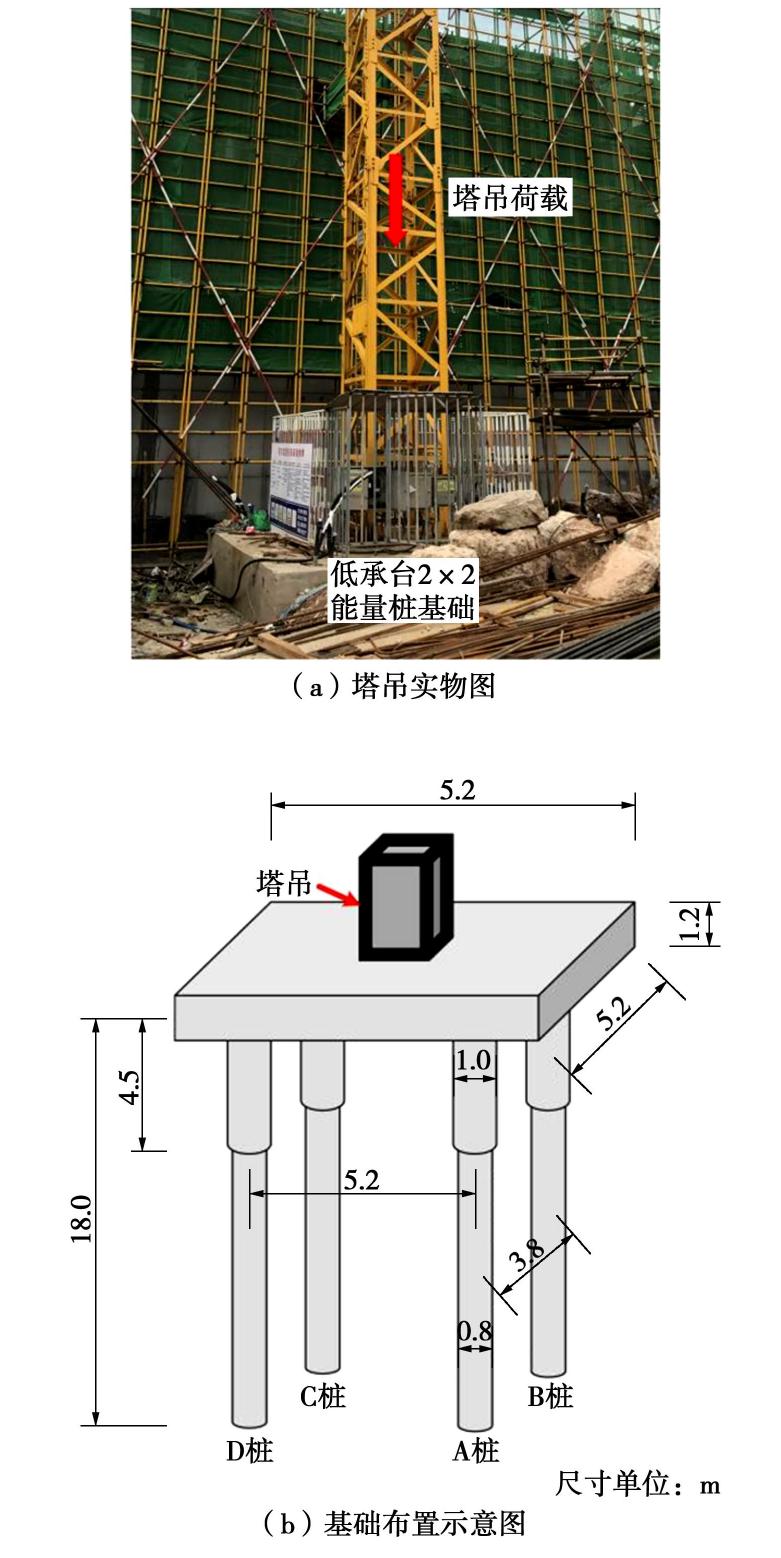

摘要: 能量桩技术是一种集地源热泵和建筑桩基功能于一体的新型节能技术。为了研究能量桩在运行过程中的热力学特性及其对基础结构的影响规律,依托低承台2×2群桩基础,开展单根能量桩加热工况下的群桩基础热力响应特性现场试验,实测能量桩、对角桩及承台的温度和应变等变化规律,着重分析能量桩本身由于温度变化引起的力学特性、及其对桩周土体、邻桩和承台等结构的影响规律。研究结果表明,本文试验条件下,加热工况下低承台2×2桩基础中单根能量桩桩身中部产生的最大约束压应力值约为3.94 MPa,约为考虑桩体被完全加热和完全约束情况下的应力上限值的48%;在温降和运行桩的共同影响下,承台中部将产生约为1.05 MPa的附加拉应力(约为混凝土抗拉强度值的43.8%);在温度和上部荷载的耦合作用下,能量桩桩顶位移达-0.6 mm,约为桩径的0.6‰。Abstract: The energy pile technology is a new energy-saving technology that integrates the functions of ground source heat pump and building pile foundation. In order to study the thermo-mechanical characteristics of energy piles and their effects on the other parts of pile foundation, field tests on the thermal response of a 2×2 pile-cap foundation under single pile heating conditions are carried out. The temperature and strain changes of energy piles, diagonal piles and cap are measured. The mechanical properties of the energy piles due to temperature changes, the influence laws on the soil around the pile and the structure of the cap are discussed. It is shown that the maximum constraint compressive stress of 3.94 MPa is generated in the middle of the pile during the summer operation of the energy piles. The condition of the thermal stresses associated with the complete heating and restraint of the pile provides a suitable upper bound for design, and the measured value is about 48% of the upper bound. Under the combined effects of atmospheric temperature and operating pile, an additional tensile stress of approximately 1.05 MPa (approximately 43.8% of the tensile strength of concrete) will be induced in the middle of the cap. The head displacement of the energy pile is about -0.6 mm (0.6‰ of pile diameter) under the thermo-mechanical coupling.

-

Keywords:

- pile-cap foundation /

- energy pile /

- temperature stress /

- thermal coupling /

- field test

-

-

表 1 土层基本物理力学性质

Table 1 Physical and mechanical properties of layered soils

土类 测试深度/m 密度/(g·cm-3) 含水率/% 塑限/% 液限/% 压缩系数α1-2 黏聚力/kPa 内摩擦角/(°) 黏土质砂 1 1.81 12.4 11.3 25.5 0.78 17.1 22.9 5 1.99 20.7 12.4 26.1 0.45 26.0 14.8 13 2.00 23.4 10.6 25.3 0.44 27.2 13.11 -

[1] BRANDL H. Energy foundations and other thermo-active ground structures[J]. Géotechnique, 2006, 56(2): 81-122. doi: 10.1680/geot.2006.56.2.81

[2] 刘汉龙, 孔纲强, 吴宏伟. 能量桩工程应用研究进展及PCC能量桩技术开发[J]. 岩土工程学报, 2014, 36(1): 176-181. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201401024.htm LIU Han-long, KONG Gang-qiang, NG W W C. Applications of energy piles and technical development of PCC energy piles[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(1): 176-181. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201401024.htm

[3] 桂树强, 程晓辉. 能量桩换热过程中结构响应原位试验研究[J]. 岩土工程学报, 2014, 36(6): 1087-1094. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201406018.htm GUI Shu-qiang, CHENG Xiao-hui. In-situ test for structural responses of energy pile to heat exchanging process[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(6): 1087-1094. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201406018.htm

[4] BOURNE-WEBB P J, AMATYA B, SOGA K, et al. Energy pile test at Lambeth College, London: geotechnical and thermodynamic aspects of pile response to heat cycles[J]. Géotechnique, 2009, 59(3): 237-248. doi: 10.1680/geot.2009.59.3.237

[5] YOU S, CHENG X, GUO H, YAO Z. In-situ experimental study of heat exchange capacity of CFG pile geothermal exchangers[J]. Energy & Buildings, 2014, 79(4): 23-31.

[6] YOU S, CHENG X, GUO H, et al. Experimental study on structural response of CFG energy piles[J]. Applied Thermal Engineering, 2016, 96: 640-651. doi: 10.1016/j.applthermaleng.2015.11.127

[7] SUTMAN M, OLGUN C G, BRETTMANN T. Full-scale field testing of energy piles[J]. Geotechnical Special Publication, 2015: 1638-1647.

[8] 路宏伟, 蒋刚, 王昊, 等. 摩擦型能量桩荷载-温度现场联合测试与承载性状分析[J]. 岩土工程学报, 2017, 39(2): 334-342. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201702022.htm LU Hong-wei, JIANG Gang, WANG Hao, et al. In-situ tests and thermo-mechanical bearing characteristics of friction geothermal energy piles[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(2): 334-342. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201702022.htm

[9] LALOUI L, NUTH M, VULLIET L. Experimental and numerical investigations of the behavior of a heat exchanger pile[J]. International Journal for Numerical & Analytical Methods in Geomechanics, 2006, 30(8): 763-781.

[10] MURPHY K D, MCCARTNEY J S, HENRY K S. Evaluation of thermo-mechanical and thermal behavior of full-scale energy foundations[J]. Acta Geotechnica, 2015, 10(2): 179-195. doi: 10.1007/s11440-013-0298-4

[11] KONG G, WU D, LIU H L, et al. Performance of a geothermal energy deicing system for bridge deck using a pile heat exchanger[J]. International Journal of Energy Research, 2019, 43(1): 596-603.

[12] 混凝土结构设计规范:GB 50010—2010[S]. 2015. Code for Design of Concrete Structure: GB50010—2010[S]. 2015. (in Chinese)

[13] 桩基地热能利用技术标准:JGJ/T 438—2018[S]. 2018. Technical Standard for Utilization of Geothermal Energy through Piles: JGJ/T 438—2018[S]. 2018. (in Chinese)

[14] MCCARTNEY J S, MURPHY K D. Strain distributions in full-scale energy foundations[J]. DFI Journal-The Journal of the Deep Foundations Institute, 2012, 6(2): 26-38.

-

期刊类型引用(7)

1. 黄波林,殷跃平,李仁江,蒋树,秦臻,张鹏,闫国强. 滑坡涌浪综合防控工程措施研究进展与挑战. 工程地质学报. 2025(01): 159-170 .  百度学术

百度学术

2. 刘红波,于磊,陈志华,陈再捷,庞富刚. 全钢集成式附着升降脚手架冲击性能研究. 施工技术(中英文). 2022(22): 72-79 .  百度学术

百度学术

3. 王文沛,殷跃平,胡卸文,李滨,刘明学,祁小博. 碎屑流冲击下桩梁组合结构拦挡效果及受力特征研究. 地质力学学报. 2022(06): 1081-1089 .  百度学术

百度学术

4. 范定坚,任曼妮. 约束空心混凝土柱抗侧向冲击动力性能. 辽宁工程技术大学学报(自然科学版). 2021(03): 214-219 .  百度学术

百度学术

5. 陈伟,谢建斌,赵一锦,孙孝海,叶海涵,林煌超. 饱和沙土中高频液压振动沉桩敏感性因素分析. 哈尔滨商业大学学报(自然科学版). 2020(02): 214-218 .  百度学术

百度学术

6. 王亚月. 钢砼叉桩动力响应模拟分析探究. 水利规划与设计. 2020(07): 102-108 .  百度学术

百度学术

7. 任根立,王秀丽. 泥石流块石冲击下钢绞线网组合结构的动力响应模拟研究. 安全与环境工程. 2019(05): 85-93 .  百度学术

百度学术

其他类型引用(6)

下载:

下载: