Analytical solutions for consolidation of a composite ground with floating stiffened deep cement mixing columns with long core piles

-

摘要: 推导出瞬时加荷情况下悬浮长芯劲性搅拌桩复合地基的固结方程和相应的定解条件,利用三层地基一维固结理论,建立了相应的固结解析解,包括桩间土和下卧层土中超静孔隙水压力解答和复合地基整体平均固结度解答。通过固结速率解析解与有限元数值解的比较,证明了解析解的合理性。利用解析解进行复合地基固结速率影响因素分析,研究了悬浮长芯劲性搅拌桩复合地基的固结性状。结果表明:悬浮长芯劲性搅拌桩复合地基的固结速率主要受桩的贯入比和下卧层刚度的影响。复合地基的固结速率随桩的贯入比和下卧层土压缩模量的增加而增大。搅拌桩壳长度、厚度和刚度以及芯桩截面含心率的变化对复合地基固结速率没有影响。增加芯桩的压缩模量只会使固结前期复合地基的固结速率略微减小,不会影响固结后期复合地基的固结速率。Abstract: The consolidation equations and the corresponding solution conditions of the composite ground with floating stiffened deep cement mixing (SDCM) columns with long core piles are derived under an instant loading. On the basis of one-dimensional consolidation theory of a third-layer soil ground, the corresponding analytical consolidation solutions are developed, including the average excess pore water pressures within the surrounding soil and underlying soil and the overall average degree of consolidation of the composite ground. The correctness and accuracy of the proposed analytical solutions are verified by comparison of the consolidation rates by the proposed analytical solution and the FEM. Some main factors are analyzed to investigate the consolidation behavior of this type of composite ground using the proposed analytical solution. The results show that the consolidation rate of the composite ground depends mainly on the penetration ratio of the SDCM columns with long core piles and the stiffness of the underlying soil. It increases with increasing penetration ratio of the pile and the constrained modulus of the underlying soil. The variations in the length, thickness and stiffness of the deep cement mixing (DCM) column sockets as well as the area core ratio of the concrete core piles have little effect on the consolidation rate of the composite ground. An increase in the modulus of the core pile decreases slightly the consolidation rate of the composite ground at the early stage of consolidation process, and it affects insignificantly the consolidation rate at the later stage of consolidation.

-

0. 引言

劲性水泥搅拌桩(SDCM column)也称“混凝土芯搅拌桩”,是一种由水泥搅拌桩(DCM column)壳和中心处较小面积预制混凝土芯桩组成的复合材料桩。按照芯桩与DCM桩壳二者长度间的相对关系,SDCM桩分为3种类型:芯桩长度小于DCM桩壳长度的短芯SDCM桩、芯桩长度等于DCM桩壳长度的等芯SDCM桩和芯桩长度大于DCM桩壳长度的长芯SDCM桩。较之传统的DCM桩,SDCM桩的竖向和水平向承载力高,沉降控制效果好。它既可作为桩基础,也可作为复合地基的竖向增强体,在国内外都得到了大量应用[1-2]。

很多学者通过室内外试验和数值模拟等方法,从承载力、荷载传递机制和控沉效果等方面对短芯SDCM桩和短芯SDCM桩复合地基进行了较为系统的研究。凌光荣等[3]、董平等[4]和吴迈等[5]通过现场单桩载荷试验研究了SDCM桩的轴向承载特性。试验发现,芯桩的插入使搅拌桩桩侧摩阻力充分发挥,SDCM桩的竖向承载力可高于混凝土灌注桩。Voottipruex等[6]采用三维有限元法研究了芯桩长度和截面积等因素对SDCM桩竖向和水平向承载力、芯桩轴力和弯矩分布的影响。吴迈等[7]、丁永君等[8]和顾士坦等[9]采用理论分析和现场实测芯桩桩身应力的方法研究了SDCM桩的荷载传递特性。Wonglert等[10-11]基于室内模型试验成果,提出短芯SDCM桩有土体破坏、芯桩底部破坏和搅拌桩壳顶部破坏3种破坏模式,研究了芯桩长度和搅拌桩壳强度对悬浮SDCM桩竖向承载力和破坏模式的影响。Wang等[12]通过现场荷载板试验,比较了刚性基础下SDCM桩复合地基与DCM桩复合地基的竖向承载力。Voottipruex等[13]和Wang等[14]进行了路堤下SDCM桩复合地基现场试验,比较了柔性基础下SDCM桩复合地基与DCM桩复合地基的沉降控制效果。叶观宝等[15-16]提出了悬浮SDCM桩复合地基桩-土应力比和沉降的计算方法。杨涛等[17]建立了端承短芯SDCM桩复合地基的固结计算模型。

近年来,随着长芯SDCM桩在中国的逐渐应用,其承载机理和设计理论的研究开始受到学术界的关注。陈华顺等[18]和程博华[19]分别提出了长芯SDCM桩桩侧摩阻力和竖向承载力的计算方法。杨涛等[20]给出了端承长芯SDCM桩复合地基固结解析解,但该解答无法用于分析悬浮长芯SDCM桩复合地基的固结问题。有鉴于此,本文研究悬浮长芯SDCM桩复合地基的固结计算方法,分析悬浮长芯SDCM桩复合地基的固结特性,进一步完善SDCM桩复合地基的固结计算理论。

1. 固结模型与基本假定

1.1 轴对称固结模型

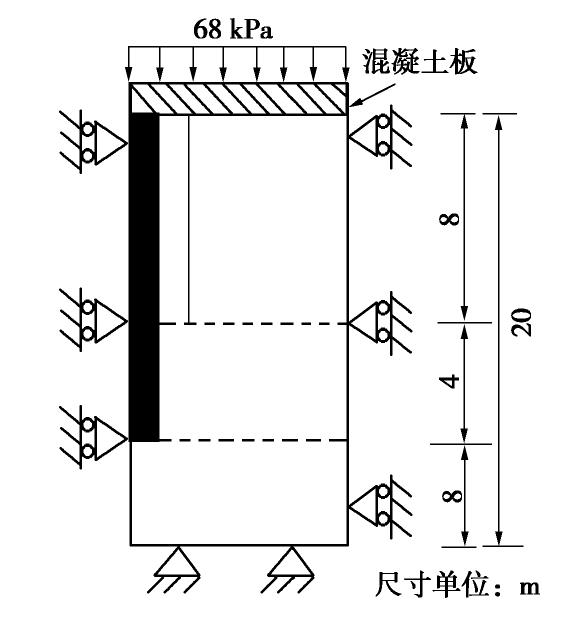

图1给出悬浮长芯SDCM桩复合地基轴对称固结模型,r和z分别是径向和竖向坐标。re为一根SDCM桩的影响区半径,可由桩的间距和布桩方式计算得到。水泥搅拌桩壳外半径和长度分别为rp和Lp=H1,上部SDCM桩的置换率为m(m=(rp/re)2),压缩模量为Ep。芯桩打穿水泥搅拌桩壳,其半径和长度分别为rsp和Lsp(Lsp=H1+H2),压缩模量为Esp。芯桩的截面含芯率为ρ(ρ=(rsp/rp)2)。根据水泥搅拌桩壳和芯桩的长度将复合地基加固区分为Ⅰ和Ⅱ二部分,加固区Ⅰ内桩间土的厚度、渗透系数、固结系数和压缩模量分别为H1,kv1,cv1,Es1,加固区Ⅱ内桩间土的厚度、渗透系数、固结系数和压缩模量分别为H2,kv2,cv2,Es2。下卧层土厚度、渗透系数、固结系数和压缩模量分别为H3,kv3,cv3,Es3。复合地基总厚度H= H1+H2+H3。

1.2 基本假定

本文公式推导采用如下假定:①地基土完全饱和,水的流动符合Darcy定律;②搅拌桩壳不排水;③芯桩桩端以下的下卧层土和搅拌桩壳以下芯桩桩端以上的土仅发生径向渗流;④芯桩与搅拌桩壳间无相对滑移,加固区中任意深度处的桩和土的竖向应变相等;⑤大面积均布荷载p瞬时施加,在待加固地基中引起的竖向附加应力沿深度均布;⑥土的渗透系数和压缩模量不随固结而变化。

2. 固结方程与定解条件

2.1 固结方程

基于前述基本假定,参考杨涛等[20-21]的研究,可得到荷载p瞬时施加情况下悬浮长芯SDCM桩复合地基得固结方程如下:

{∂ˉus1∂t=cv1e∂2ˉus1∂z2(0≤z<H1) ,∂ˉus2∂t=cv2e∂2ˉus2∂z2(H1≤z<H1+H2) ,∂ˉus3∂t=cv3e∂2ˉus3∂z2(H1+H2≤z≤H) 。 (1) cv1e=(1+m[ρEsp+(1−ρ)Ep](1−m)Es1)cv1, (2) cv2e=(1+mρEsp(1−mρ)Es2)(1−m1−mρ)cv2, (3) cv3e=(1−mρ)cv3 。 (4) 式中

ˉus1 ,ˉus2 ,ˉus3 分别为加固区Ⅰ、Ⅱ中桩间土和下卧层土中任意深度z处的平均超静孔隙水压力;cv1e,cv2e,cv3e分别为考虑劲性桩和芯桩影响的加固区Ⅰ、Ⅱ中桩间土和下卧层土的等效竖向固结系数。2.2 定解条件

(1)边界条件

考虑复合地基上边界排水、下边界不排水的单面排水情况,边界条件如下:

z=0,ˉus1=0, (5) z=H,∂ˉus3∂z=0。 (6) (2)孔压和水流连续性条件

考虑到

(1−m)ˉus1 和(1−mρ)ˉus2 分别为加固区Ⅰ和加固区Ⅱ内任意深度处的平均孔压,可得加固区Ⅰ与加固区Ⅱ分界面处、加固区Ⅱ与下卧层分界面处孔压和水流连续性条件如下:z=H1时,

(1−m)ˉus1=(1−mρ)ˉus2, (7) (1−m)kv1∂ˉus1∂z=(1−mρ)kv2∂ˉus2∂z。 (8) z=H1+H2时,

(1−mρ)ˉus2=ˉus3, (9) (1−mρ)kv2∂ˉus2∂z=kv3∂ˉus3∂z。 (10) (3)初始条件

荷载施加的瞬时,桩间土和下卧层土中没有竖向变形。参照杨涛等[20-21]的研究,容易写出如下初始条件:

ˉus1(z,0)=p1−m, (11) ˉus2(z,0)=p1−mρ, (12) ˉus3(z,0)=p。 (13) 3. 固结解析解

3.1 方程与定解条件的函数变换

为便于求解,进行如下函数变换:

{ˆus1=(1−m)ˉus1 ,ˆus2=(1−mρ)ˉus2 ,ˆus3=ˉus3 。 (14) 显然,

ˆus1 和ˆus2 分别是复合地基上、下加固区任意深度处的平均超静孔隙水压力。将式(14)代入固结控制方程式(1)和定解条件式(5)~(13),则变换后的复合地基固结控制方程和求解条件如下:{∂ˆus1∂t=cv1e∂2ˆus1∂z2(0≤z<H1) ,∂ˆus2∂t=cv2e∂2ˆus2∂z2(H1≤z<H1+H2) ,∂ˆus3∂t=cv3e∂2ˆus3∂z2(H1+H2≤z≤H) 。 (15) z=0:ˆus1=0, (16) z=H:∂ˆus3∂z=0, (17) z=H1,

{ˆus1=ˆus2kv1∂ˆus1∂z=kv2∂ˆus2∂z, (18) z=H1+H2,

{ˆus2=ˆus3kv2∂ˆus2∂z=kv3∂ˆus3∂z, (19) ˆus1(z,0)=ˆus2(z,0)=ˆus3(z,0)=p。 (20) 3.2 固结解析解

显然,式(15),(16)~(20)分别是瞬时荷载p作用在由复合地基上、下加固区复合土和下卧层土组成的三层土系统固结问题的固结方程和定解条件。与瞬时荷载p作用下的三层天然地基固结问题相比,只是各层天然地基土的固结系数cv1,cv2和cv3分别被cv1e,cv2e和cv3e代替而已。设三层土系统中土层i的渗透系数为kvi(i=1,2,3),则其压缩模量为Esie=cvierw/kvi (i=1,2,3)。

为使计算公式得以简化,定义5个无量纲参数:

ai=kvikv1;bi=Es1eEsie;ci=HiH1;μi=√biai(i=1,2,3);di=√ai−1bi−1aibi (i=2,3)。} (21) 根据谢康和[22]的研究,容易得到:

(1)各加固区和下卧层的平均超静孔压

{ˆus1(z,t)=p∞∑m=1Cmsin(λmzH1)e−λ2mTv1e ,ˆus2(z,t)=p∞∑m=1Cm[sin(λm)cos(μ2λmz−H1H1)+ d2cos(λm)sin(μ2λmz−H1H1)]e−λ2mTv1e ,ˆus3(z,t)=p∞∑m=1CmAmcos(μ3c3λm)cos(μ3λmH−zH1)e−λ2mTv1e , (22) Tv1e=cv1et/H21。 (23) (2)桩间土和下卧层土的平均孔压

将式(14)代入式(22),可得悬浮长芯SDCM桩复合地基上、下部加固区中桩间土和下卧层土平均超静孔隙水压力:

{ˉus1(z,t)=p1−m∞∑m=1Cmsin(λmzH1)e−λ2mTv1e ,ˉus2(z,t)=p1-mρ∞∑m=1Cm[sin(λm)cos(μ2λmz−H1H1)+d2cos(λm)sin(μ2λmz−H1H1)]e−λ2mTv1e ,ˉus3(z,t)=p∞∑m=1CmAmcos(μ3c3λm)cos(μ3λmH−zH1)e−λ2mTv1e , (24) Cm=2d2sin(2μ3c3λm)λm[sin(2μ3c3λm)(d2+μ2c2Fm)−μ3c3Dm], (25) Am=sin(λm)cos(μ2c2λm)+d2cos(λm)sin(μ2c2λm), (26) Dm=sin(2μ2c2λm)Em−d2sin(2λm)cos(μ2c2λm), (27) Em=sin2(λm)−d22cos2(λm), (28) Fm=sin2(λm)+d22cos2(λm)。 (29) 按下面方程求解出特征值

λm :Am+d3cot(μ3c3λm)Bm=0, (30) Bm=sin(λm)sin(μ2c2λm)−d2cos(λm)cos(μ2c2λm)。 (31) (3)复合地基整体平均固结度

参考谢康和[22]的研究,容易得到悬浮长芯SDCM桩复合地基按沉降定义和按孔压定义的整体平均固结度Us和Up的计算公式:

Us=1−∞∑m=1Cmλm(1+b2c2+b3c3)e−λ2mTv1e, (32) Up=1−∞∑m=1√a2b2Bm(b3−b2)+b2b3+(b3−b2b3)cos(λm)λmb2c3(1+c2+c3)⋅Cme−λ2mTv1e。 (33) 4. 算例验证

算例中,H=20 m,re=1.1 m;芯桩:rsp=0.175 m,Lsp= H1+ H2=12 m,Esp=20 GPa,泊松比μsp=0.17。搅拌桩壳:rp=0.35 m,Lp=H1=8 m,Ep=150 MPa,泊松比μp=0.25。地基土:H3=8 m,Es1=Es2=3 MPa,Es3=9 MPa,kv1=kv2=kv3=10-8 m/s,泊松比μs=0.35。为了在数值计算中近似模拟等应变条件,在复合地基表面铺设0.5 m厚的混凝土板,板上荷载p=68 kPa瞬时施加。混凝土板压缩模量和泊松比与芯桩相同。地基土、芯桩、搅拌桩壳和混凝土板均采用线弹性模型。在各材料的弹性模量E和压缩模量E1之间按E= (1+ μ)(1-2μ)E1/(1-μ)近似换算,μ为泊松比。图2为悬浮长芯SDCM桩复合地基轴对称有限元模型。模型左、右侧边界上约束径向位移,不排水。模型底边界上径向和竖向均约束,不排水。复合地基表面自由,排水。

采用ABAQUS有限元软件进行算例固结分析。混凝土板、芯桩和搅拌桩壳采用4结点四边形单元(CAX4)剖分,桩间土采用应力-孔压耦合4结点四边形单元(CAX4P)剖分。芯桩-土交界处设置摩擦接触对,摩擦系数取0.42。模型共剖分2466个单元,结点总数2742个。

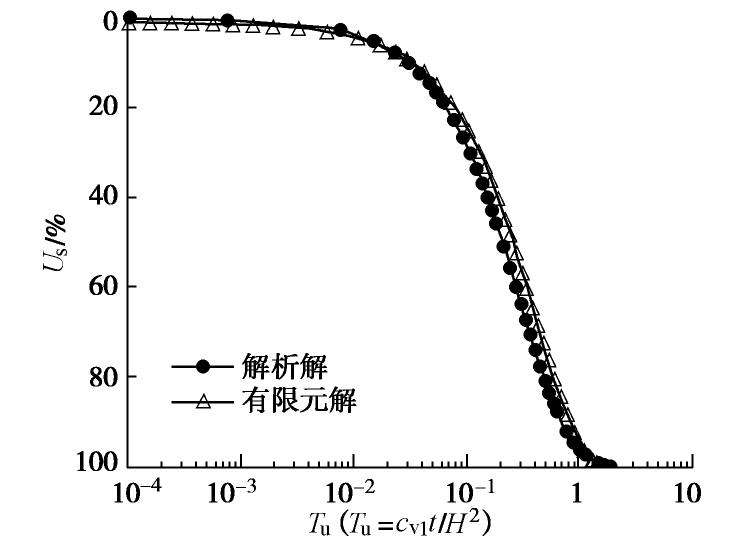

图3给出本文解析解计算的悬浮长芯SDCM桩复合地基整体平均固结度(Us)曲线与有限元计算结果的比较,时间轴采用无量纲时间因数Tu=cv1t/H2。图3表明,本文解析解与有限元计算结果较为接近,解析解数值略大于数值解,二者差值最大不超过3.0%。计算表明,解析解有较高的计算精度。

5. 复合地基结性状分析

采用的几何和力学参数基准值如下:H=20 m,H1=10 m,H2=5 m,H3=5 m。m=0.1,

ρ =0.25。Ep=150 MPa,Esp=20 GPa。Es1=Es2=3 MPa,Es3=9 MPa。kv1=kv2=kv3=10-8 m/s。(1)桩的贯入比的影响

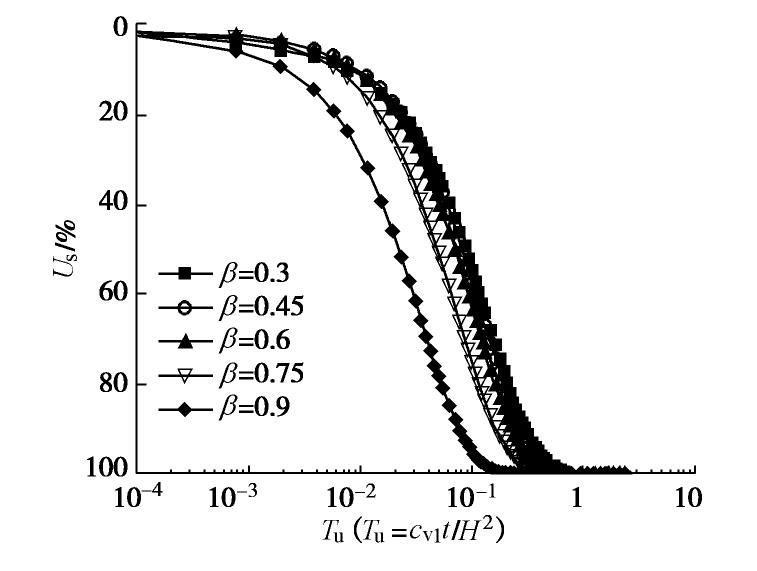

图4给出长芯SDCM桩贯入比

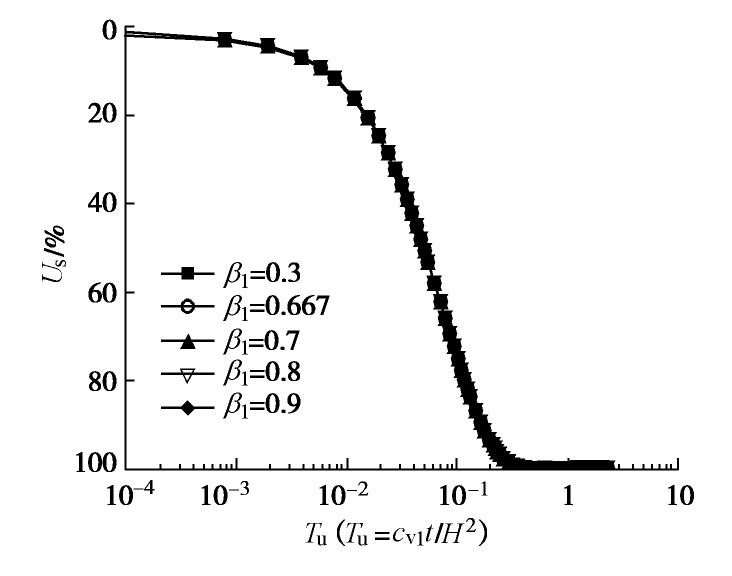

β =Lsp/H的变化对复合地基固结速率的影响,计算时地基土为均质土,Es3=3 MPa,搅拌桩壳长度与芯桩长度的比值β1 =Lp/ Lsp=0.67保持不变。图4表明,复合地基的固结速率随着长芯SDCM桩贯入比的增加逐渐增大,当β >0.75以后,复合地基固结速率的增加率显著增大。(2)搅拌桩壳的刚度和几何尺寸的影响

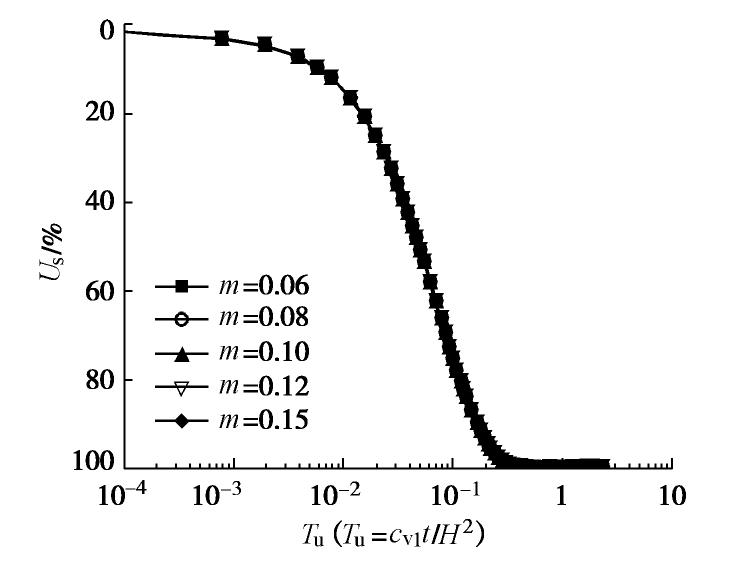

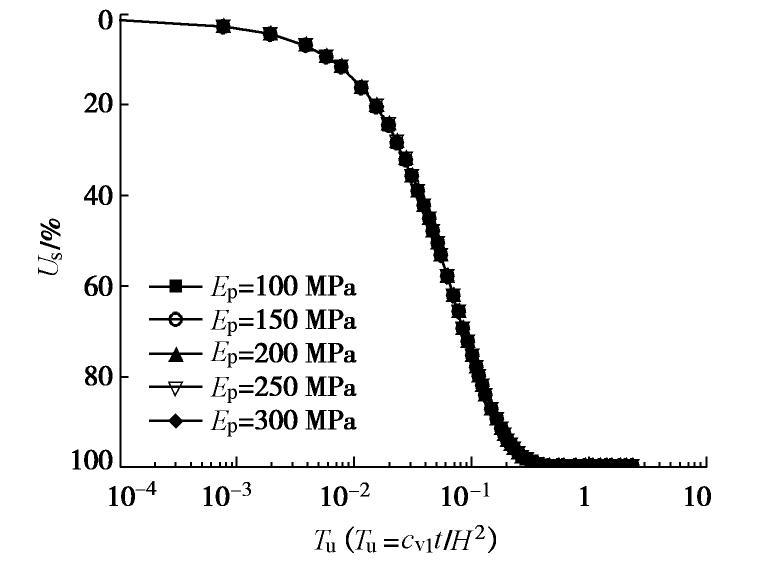

图5~7分别给出上部SDCM桩置换率m、搅拌桩壳长度与芯桩长度之比

β1 =Lp/Lsp和搅拌桩壳压缩模量Ep的变化对复合地基固结速率的影响。在图5固结度曲线计算中,芯桩截面积保持不变,即miρi=mρ=0.025,m越大表示搅拌桩壳的厚度越大。图5~7计算结果表明,搅拌桩壳的厚度、长度和压缩模量的变化对悬浮长芯SDCM桩复合地基的固结速率没有影响。(3)芯桩刚度和含心率的影响

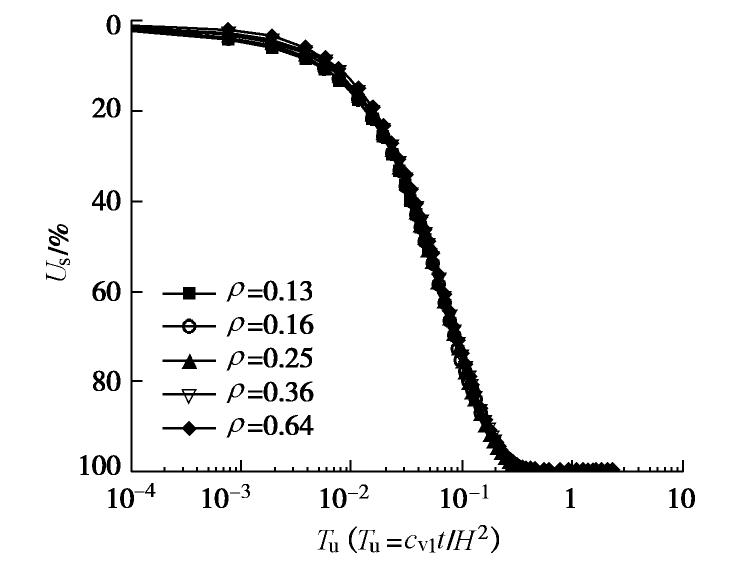

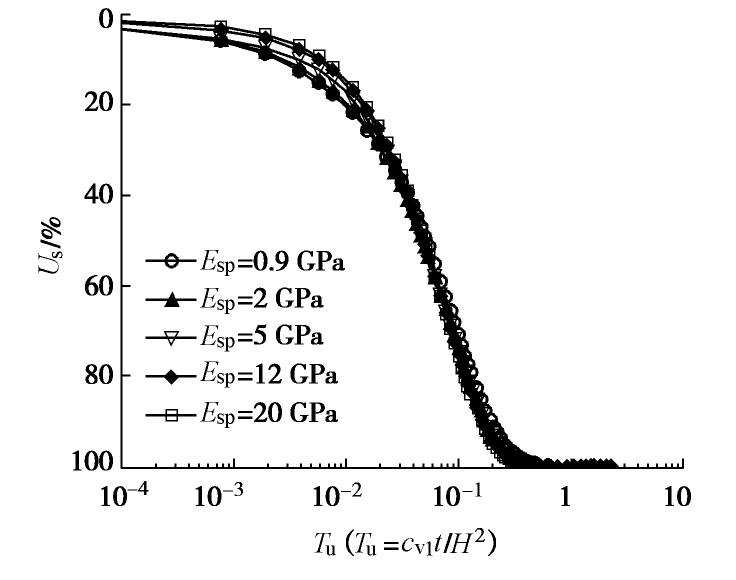

图8,9分别给出芯桩的截面含芯率

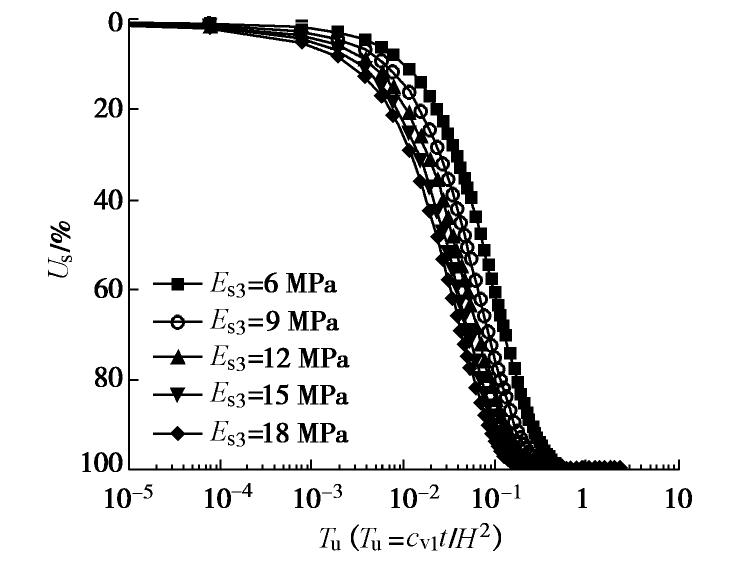

ρ 和压缩模量Esp的变化对复合地基固结速率的影响。图8表明,芯桩含芯率ρ 的变化对悬浮长芯SDCM桩复合地基固结速率近乎没有影响。当含芯率ρ 增大时,仅在固结前期复合地基的固结速率会略微减小,但降幅非常小,可以忽略不计。从图9中可见,芯桩压缩模量Esp的变化对悬浮长芯SDCM桩复合地基前期的固结速率有一定影响。随着Esp数值的增加,前期复合地基固结速率随之减小,但降幅并不大。总的来看,芯桩刚度的变化对复合地基固结速率的影响不大。(4)下卧层土体刚度的影响

图10给出下卧层土压缩模量Es3取不同数值情况下悬浮长芯SDCM桩复合地基的Us-Tu曲线。图10表明,复合地基的固结速率随下卧层土刚度的增加而增大。这说明,将芯桩的桩端置于承载力较大的持力层上可加速复合地基的固结。

6. 结论

(1)本文固结解析解是基于加固区等竖向应变假定获得的,因此,它更适用于刚性基础下悬浮长芯SDCM桩复合地基的固结分析。

(2)桩的贯入比和下卧层土的刚度是影响悬浮长芯SDCM桩复合地基固结快慢的主要因素。桩的贯入比和下卧层土的压缩模量越大,悬浮长芯SDCM桩复合地基的固结越快。

(3)芯桩截面含芯率的变化不会影响悬浮长芯SDCM桩复合地基的固结速率。芯桩刚度的增加会略微减小固结前期复合地基的固结速率,对后期复合地基的固结速率没有影响。

(4)搅拌桩壳的厚度、长度和刚度的变化对悬浮长芯SDCM桩复合地基的固结速率没有影响。

-

[1] ZHENG G, GU X L, LING G R. Development and practice of composite DMM column in China[C]//Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering. Osaka, 2005: 1295-1299.

[2] HAN J. Recent research and development of ground column technologies[J]. Ground Improvement,2015,168(4): 1-19.

[3] 凌光容, 安海玉, 谢岱宗, 等. 劲性搅拌桩的试验研究[J]. 建筑结构学报, 2001, 22(2): 92-96. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB200102017.htm LING Guang-rong, AN Hai-yu, XIE Dai-zong, et al. Experimental study on concrete core mixing pile[J]. Journal of Building Structure, 2001, 22(2): 92-96. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB200102017.htm

[4] 董平, 陈征宙, 秦然. 砼芯水泥土搅拌桩在软土地基中的应用[J]. 岩土工程学报, 2002, 24(2): 204-207. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC200202017.htm DONG Ping, CHEN Zheng-zhou, QIN Ran. Use of concrete-cored DCM pile in soft ground[J]. Chinese Journal of Geotechnical Engineering, 2002, 24(2): 204-207. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC200202017.htm

[5] 吴迈, 赵欣, 窦远明, 等. 水泥土组合桩室内试验研究[J]. 工业建筑, 2004, 34(11): 45-48. https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ200411011.htm WU Mai, ZHAO Xin, DOU Yuan-ming, et al. Experimental study of stiffened DCM pile in laboratory[J]. Industrial Construction, 2004, 34(11): 45-48. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ200411011.htm

[6] VOOTTIPRUEX P, SUKSAWAT T, BERGADO D T, et al. Numerical simulations and parametric study of SDCM and DCM piles under full scale axial and lateral loads[J]. Computers and Geotechnics, 2011, 38: 318-329. doi: 10.1016/j.compgeo.2010.11.006

[7] 吴迈, 窦远明, 王恩远. 水泥土组合桩荷载传递试验研究[J]. 岩土工程学报, 2004, 26(3): 432-435. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC200403034.htm WU Mai, DOU Yuanming, WANG Enyuan. A study on load transfer mechanism of stiffened DCM pile[J]. Chinese Journal of Geotechnical Engineering, 2004, 26(3): 432-435. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC200403034.htm

[8] 丁永君, 李进军, 刘峨, 等. 劲性搅拌桩的荷载传递规律[J]. 天津大学学报(自然科学与工程技术版), 2010, 43(6): 530-536. https://www.cnki.com.cn/Article/CJFDTOTAL-TJDX201006012.htm DING Yong-jun, LI Jin-jun, LIU E, et al. Load transfer mechanism of reinforced mixing pile[J]. Journal of Tianjin University (Science and Technology), 2010, 43(6): 530-536. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TJDX201006012.htm

[9] 顾士坦, 施建勇, 王春秋, 等. 劲性搅拌桩芯桩荷载传递规律理论研究[J]. 岩土力学, 2011, 32(8): 2473-2478. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201108038.htm GU Shi-tan, SHI Jian-yong, WANG Chun-qiu, et al. Theoretical study of core pile load transfer regularity of reinforced mixing pile[J]. Rock and Soil Mechanics, 2011, 32(8): 2473-2478. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201108038.htm

[10] WONGLERT A, JONGPRADIST P. Impact of reinforced core on performance and failure behavior of stiffened deep cement mixing piles[J]. Computers and Geotechnics, 2015, 69: 93-104.

[11] WONGLERT A, JONGPRADIST P, JAMSAWANG P, et al. Bearing capacity and failure behaviors of floating stiffened deep cement mixing column under axial load[J]. Soils and Foundations, 2018, 58(2): 446-461.

[12] WANG C, XU Y F, DONG P. Plate load tests of composite foundation reinforced by concrete-cored DCM pile[J]. Geotechnical and Geological Engineering, 2014, 32(1): 85-96.

[13] VOOTTIPRUEX P, BERGADO D T, SUKSAWAT T, et al. Behavior and simulation of deep cement mixing (DCM) and stiffened deep cement mixing (SDCM) piles under full scale loading[J]. Soils and Foundations, 2011, 51(2): 307-320.

[14] WANG C, XU YF, DONG P. Working characteristics of concrete-cored deep cement mixing piles under embankments[J]. Journal of Zhejiang University (Applied Physics & Engineering), 2014, 15(6): 419-431.

[15] 叶观宝, 蔡永生, 张振. 加芯水泥土桩复合地基桩土应力比计算方法研究[J]. 岩土力学, 2016, 37(3): 672-678. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201603009.htm YE Guan-bao, CAI Yong-shen, ZHANG Zhen. Research on calculation of pile-soil stress ratio for composite foundation reinforced by stiffened deep mixed piles[J]. Rock and Soil Mechanics, 2016, 37(3): 672-678. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201603009.htm

[16] YE G B, RAO F R, ZHANG Z, et al. Calculation method for settlement of stiffened deep mixed column-supported embankment over soft clay[C]//Proceedings of Geoshanghai 2018 International Conference. Shanghai, 2018: 22-29.

[17] 杨涛, 唐凤. 变荷载下劲性搅拌桩复合地基固结分析[J]. 建筑结构学报, 2017, 38(9): 160-166. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB201709019.htm YANG Tao, TANG Feng. Consolidation analysis of composite ground with stiffened deep cement mixing columns under time- dependent loading[J]. Journal of Building Structures, 2017, 38(9): 160-166. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB201709019.htm

[18] 陈华顺, 孙元奎, 李挺. 长芯劲性桩桩侧摩阻力计算方法探讨[J]. 水运工程, 2011(5): 40-44. https://www.cnki.com.cn/Article/CJFDTOTAL-SYGC201105009.htm CHEN Huai-shun, SUN Yuan-kui, LI Ting. Calculation method for side friction of stiffened piles with long core pile[J]. Port & Waterway Engineering, 2011(5): 40-44. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SYGC201105009.htm

[19] 程博华. 基于破坏模式的长芯劲性搅拌桩竖向承载力计算方法研究[J]. 铁道建筑技术, 2016(6): 102-106. https://www.cnki.com.cn/Article/CJFDTOTAL-TDJS201606029.htm CHENG Bo-hua. Study on calculation method of vertical bearing capacity of long core strength mixing pile based on failure mode[J]. Railway Construction Technology, 2016(6): 102-106. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TDJS201606029.htm

[20] 杨涛, 戴基彤, 王恒栋. 刚性基础下T形劲性搅拌桩复合地基固结解析解[J]. 工业建筑, 2018, 48(9): 105-110. https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ201809017.htm YANG Tao, DAI Ji-tong, WANG Heng-dong. Analytical solution for consolidation of a composite ground with T-shaped stiffened deep cement mixing columns under rigid foundation[J]. Industrial Construction, 2018, 48(9): 105-110. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ201809017.htm

[21] YANG T, YANG J Z, NI J. Analytical solution for the consolidation of a composite ground reinforced by partially penetrated impervious column[J]. Computers and Geotechnics, 2014, 57: 30-36.

[22] 谢康和. 成层地基一维固结理论研究最新进展[C]//第二届岩土力学与工程学术讨论会论文集. 杭州: 浙江大学出版社, 1995: 1-9. XIE Kang-he. The new development of one-dimensional consolidation theory of layered soil ground[C]//Proceedings of 2nd Conference on Soil Mechanics and Geotechnical Engineering. Hangzhou: Zhejiang University Press, 1995: 1-9. (in Chinese)

-

期刊类型引用(1)

1. 朱庆华,朱志慧,左威龙,费康. 劲性搅拌桩复合地基承载特性数值分析. 河南理工大学学报(自然科学版). 2022(01): 181-188 .  百度学术

百度学术

其他类型引用(10)

下载:

下载: