Normalized interface friction coefficient versus corrective corrected roughness Rr

Figures of the Article

-

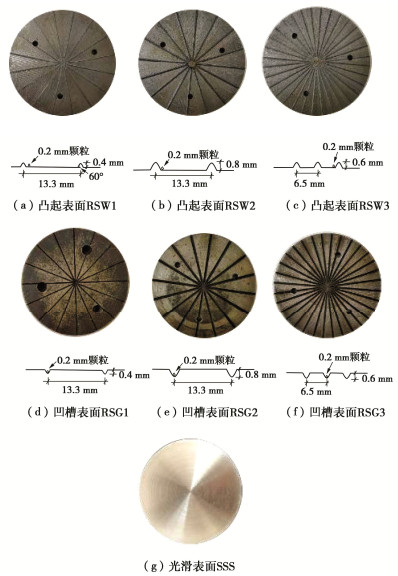

![]() Steel plates used in tests

Steel plates used in tests

-

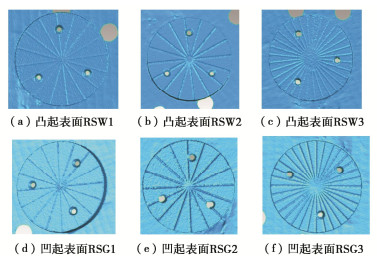

![]() Laser-scanned images of different rough surfaces

Laser-scanned images of different rough surfaces

-

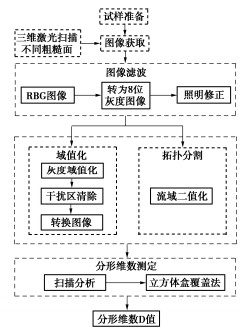

![]() Flow chart of surface fractal dimension calculated by Image J software

Flow chart of surface fractal dimension calculated by Image J software

-

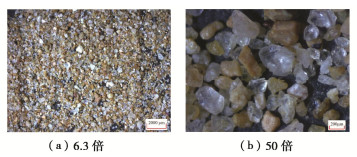

![]() Microscopic images of quartz sand particles

Microscopic images of quartz sand particles

-

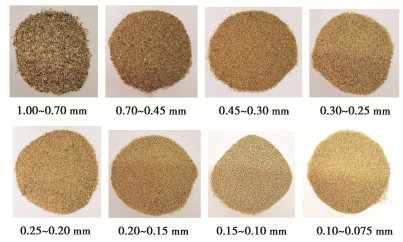

![]() Sand particles at different ranges of grain sizes

Sand particles at different ranges of grain sizes

-

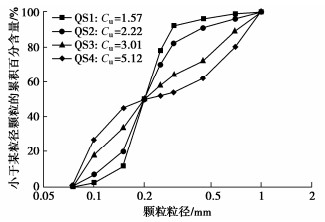

![]() Grain size distributions of the testing soils

Grain size distributions of the testing soils

-

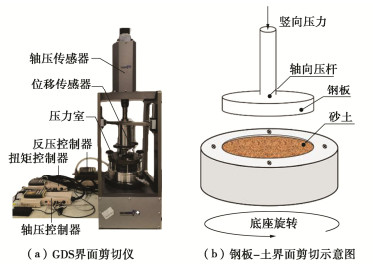

![]() GDS interface shear apparatus

GDS interface shear apparatus

-

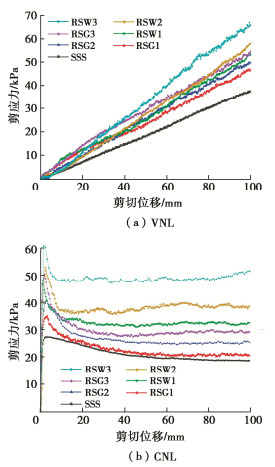

![]() Curves of shear stress-shear displacement for different interfaces under VNL and CNL conditions

Curves of shear stress-shear displacement for different interfaces under VNL and CNL conditions

-

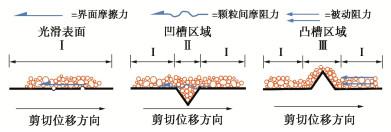

![]() Mobilization mechanism of interface shear strength

Mobilization mechanism of interface shear strength

-

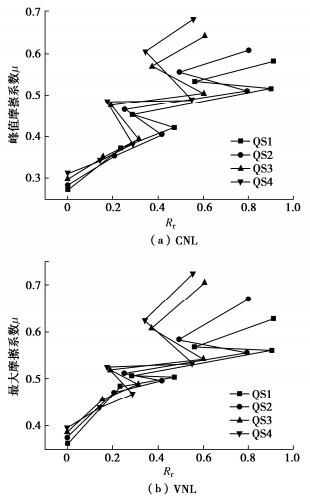

![]() Interface friction coefficient versus interface roughness Rr

Interface friction coefficient versus interface roughness Rr

-

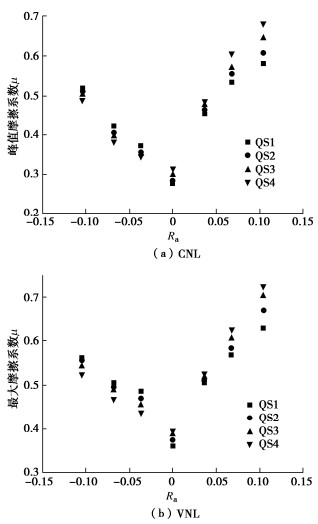

![]() Interface friction coefficient versus interface roughness Ra

Interface friction coefficient versus interface roughness Ra

-

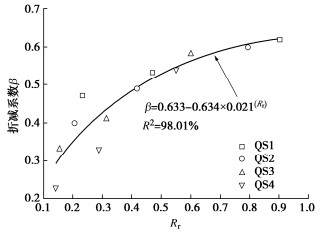

![]() Curves of interface roughness reduction factor-roughness Rr

Curves of interface roughness reduction factor-roughness Rr

-

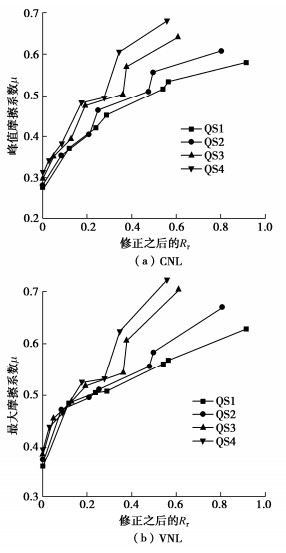

![]() Interface friction coefficient versus corrective interface roughness $ {R_{\text{r}}} $

Interface friction coefficient versus corrective interface roughness $ {R_{\text{r}}} $

-

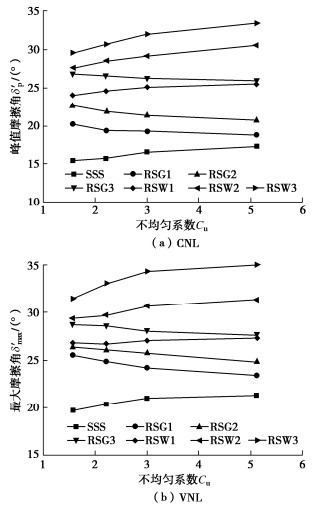

![]() Variations of interface friction angle with Cu

Variations of interface friction angle with Cu

-

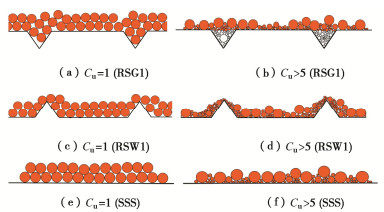

![]() Interpretation of interface interactions

Interpretation of interface interactions

-

![]() Normalized interface friction coefficient versus corrective corrected roughness Rr

Normalized interface friction coefficient versus corrective corrected roughness Rr

Tables of the Article

-

Soil properties

编号 Cu Cc D50/

mmDav/

mm相对密实度Dr/% emax emin 砂样质量/g QS1 1.57 0.99 0.20 0.22 90 1.10 0.61 129.81 QS2 2.22 1.23 0.25 1.01 0.56 128.67 QS3 3.01 0.80 0.33 0.98 0.63 124.28 QS4 5.12 0.33 0.36 1.02 0.65 122.63 -

Surface roughnesses of different interfaces

表面类型 Rmax/mm Rn Ra/mm D Rr QS1 QS2 QS3 QS4 SSS 0 0 0 0 0 0 0 0 RSW1 0.4 2 0.0365 1.7252 0.286 0.252 0.191 0.175 RSW2 0.8 4 0.0678 1.8269 0.563 0.495 0.375 0.344 RSW3 0.6 3 0.1043 1.9251 0.913 0.803 0.608 0.558 RSG1 0.4 2 0.0365 1.421 0.236 0.207 0.157 0.144 RSG2 0.8 4 0.0678 1.5376 0.474 0.417 0.316 0.290 RSG3 0.6 3 0.1043 1.9047 0.903 0.795 0.602 0.552 -

Shear tests on saturated interfaces

表面类型 试样 CNL/

kPaVNL/

kPa剪切位移

L/mm剪切速率/

(cm·min-1)SSS, RSW1,

RSW2, RSW3,

RSG1, RSG2,

RSG3QS1,

QS2,

QS3,

QS4100 0~100 100 1.0

Download:

Download: