Effects of in-situ jet grouting-aided chemical oxidation on geotechnical properties of petroleum hydrocarbon-contaminated silty clay

-

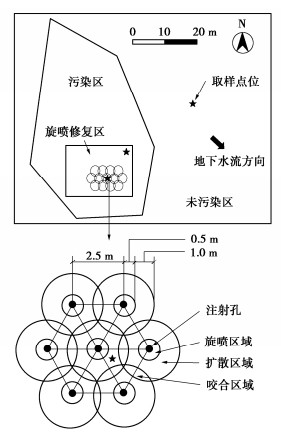

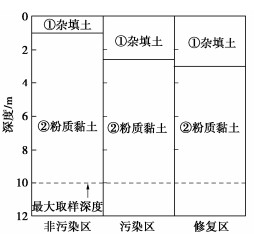

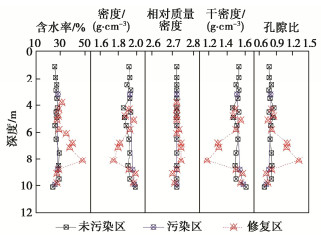

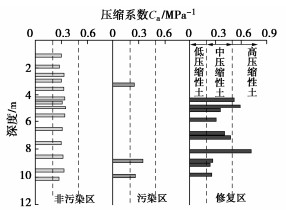

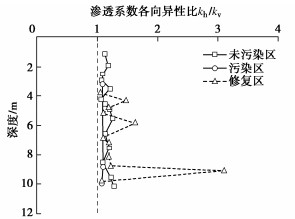

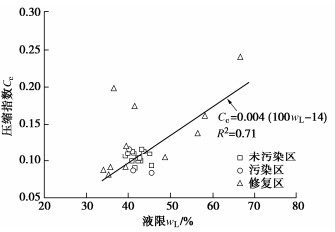

摘要: 化学氧化广泛应用于石油烃污染土壤修复,但化学氧化作用对石油烃污染黏性土工程特性的影响尚不明晰。通过原位高压旋喷化学氧化试验,对比分析石油烃污染与氢氧化钠活化过硫酸钠氧化作用对长江下游地区粉质黏土工程特性的影响,并定量评价石油烃污染和化学氧化作用对土的工程特性影响程度。结果表明:石油烃污染(720 mg/kg)对粉质黏土的渗透性影响程度为中等;掺量为3%的氢氧化钠活化过硫酸钠氧化作用对石油烃污染土的干密度影响程度为中等,对含水率、孔隙比、界限含水率、压缩性、渗透性影响程度为大;未污染土、污染土和修复土的压缩指数与液限存在良好的线性关系;未污染土和污染土的渗透系数与孔隙比在半对数坐标系中存在良好的正相关关系;而修复土的渗透系数与孔隙比关联关系较差。研究结果为长江经济带类似污染场地的修复与安全再利用提供指导。Abstract: The chemical oxidation is a widely used remediation technology for petroleum hydrocarbon-contaminated soils. However, the effects of in-situ chemical oxidation on the geotechnical properties of contaminated soils are unclear. An in-situ jet grouting-aided chemical oxidation test is conducted at a petroleum hydrocarbon-contaminated site located at the lower reaches of the Yangtze River. The effects of petroleum hydrocarbon-contamination and chemical oxidation on the geotechnical properties of the studied silty clay are investigated, and the corresponding degrees of effects (DOEs) of series geotechnical parameters are evaluated as per China GB 50021-2001. The test results show that the DOEs of petroleum hydrocarbon-contamination (720 mg/kg) on the hydraulic conductivity are moderate. The DOEs of sodium hydroxide-activated sodium persulfate addition (3%) on the dry density are moderate, and those on the water content, void ratio, Atterberg limits, compressibility and hydraulic conductivity are significant. The compression indexes and the liquid limits of clean, contaminated, and treated soils exhibit a linear relationship. Furthermore, a positive correlation relationship is observed between the hydraulic conductivity and the void ratio of the clean and contaminated soils on the semilogarithm coordinate.

-

Keywords:

- chemical oxidation /

- petroleum hydrocarbon /

- silty clay /

- geotechnical property /

- jet grouting

-

0. 引言

《岩土工程勘察规范》规定:当薄层与厚层的厚度比大于1/3时,定为“互层”[1]。互层土多为滨海相、河滩相的典型沉积土层,属三角洲、河漫滩冲积成因[2],呈现出一种“千层饼”状外貌。互层土的空间分布较为复杂,呈明显各向异性,其特殊性质给地下空间开发带来一定挑战[3-5]。

当互层土的层厚与工程结构物或数值模拟中的单元尺寸相比小得多时,互层结构可作为土体材料的内在结构特征,互层土试样可作为代表性单元用于研究其力学特性。已有互层土力学特性研究多以原状土为主,庄海洋等[6]、陈国兴等[7]对原状互层土进行了动力特性研究,表明互层土具有的特殊“千层饼”构造对其动力特性有较大影响,与单纯的砂性土和黏性土存在明显差别。但原状土在取样过程中很容易被扰动且难以恢复,加之原状互层土类型复杂,变异性强,难以通过试验揭示该类土的力学特性规律及内在机理。因此,制备高质量的互层土并系统开展力学特性试验具有重要的理论意义。Patel等[8]采用分层压实法制备了不同性质黏性土层构成的互层土试样,但该方法在层间易产生明显的分界,且击实法难以形成大孔隙比试样。Yoshimine和Koike[9]采用空中砂雨法制备了较大粒径和较小粒径砂层构成的互层砂土,但该方法只适用于颗粒尺寸分明的砂样。Amini和Qi[10]采用水沉法制备了粉砂和粉土的互层土。Jia和Wang[11]采用水沉法制备了细砂和粉土的互层土。对于工程中普遍存在的、由土性差别很大的黏性土与砂土构成的互层土,目前尚无文献报道高质量的制样方法。为此,本文提出一种重塑互层土的制样方法并验证了该方法的制样可重复性。

1. 互层土制样用土及装置

1.1 试样制备用土

本试验所制备的互层重塑样为粉质黏土与粉砂互层土。所用粉质黏土和粉砂均取自南京漫滩相地层。粉质黏土的主要物理性质指标见表1。粉砂的Gs=2.68,最小孔隙比emin=0.75,最大孔隙比emax=1.35,级配如图1所示。

表 1 粉质黏土物理性质Table 1. Physical properties of silty clayw/% γ/(kN·m-3) Gs wL/% wP/% IP 39.6 17.6 2.72 36.8 23.3 13.5 1.2 互层土试样制备装置

本研究提出了一种可制备互层土的装置,如图2所示。主要包括亚克力质地的透明三瓣模(便于观察层面情况),上下钢质环箍,上下透水石,圆筒形底座。三瓣模组装后内径51 mm、高150 mm、壁厚5 mm,钢质环箍直径可在40~63 mm范围调节,顶部透水石直径50 mm、厚度10 mm,底部透水石直径83 mm、厚度10 mm。圆筒形底座内径98 mm,外径100 mm,高10 mm。

图2中制备薄粉砂层的冻结模具由具有一定延展性的透明亚克力材料制成,以方便脱模。冻结模具上部平面上为一个长、宽均为60 mm的正方形薄板,厚度3 mm,薄板的中间部分为下凹的有底薄圆饼状空间用来盛粉砂和水,下凹部分内径49.9 mm,净深度4 mm。为方便将冻结粉砂层填入图2中三瓣模拼装而成的圆柱形空间中,配备专门的钢质砂层装样柄,该装样柄一端为圆饼状且端面粗糙,直径略小于冻结薄砂层的直径,能保证砂层平稳放置且易与冻结砂层脱离。

2. 互层土样制备方法

2.1 制样步骤

以制备粉质黏土-粉砂互层土试样为例介绍操作步骤。试样各层分层装入图2装置中,粉质黏土层厚7 mm,粉砂层的层厚4 mm,二者比值为1.75;粉质黏土共14层,粉砂共13层,整个试样高度150 mm。制样后将试样放入改装的固结仪中预压固结。

将原粉质黏土烘干,取打土机打碎过筛后的干土粉,配置到需要的含水率,充分搅拌后装入密封袋密闭24 h后待用。分层装样中的黏土含水率不宜过低,否则无法保持良好的流动状态并无法与砂层有良好的接触,在装样时对砂层扰动较大且不易保持层面平整。经试验,发现配置含水率为1.63倍液限的泥膏效果较好。

结合图3介绍重塑互层样制备的具体操作步骤。①将预先配置好的泥膏充分搅拌均匀备用。②控制粉砂干密度,将一定质量的干砂倒入冻结模具凹槽内使之完全填满,且保持表面平整。③加水至砂恰好湿润,放入冰箱内冷冻,为防止失水,冷冻的时间不宜过长。④冷冻成型后,拿出脱模,将脱模后砂层重新放入冰箱内,以备后续装样。⑤滤纸沾湿,放在饱和透水石上,将透水石放置于底座中,在三瓣模内部抹上凡士林,将其固定好箍上环箍,试样制备装置准备完成。⑥为保证分层均匀,控制每层装入泥膏的质量一定,本试验控制每层装入的泥膏质量为24g(通过天平称重、并考虑各装样辅助工具黏附的泥膏),将泥膏缓慢装入三瓣模。⑦用细木棍轻戳泥膏,散出泥膏中的气泡,同时抹平表面。⑧将装样柄底部略微沾湿,不宜沾水过多,保证颗粒粗糙面略微湿润即可,置于砂层中心接触40~50 s后迅速取出。⑨用长镊子小心夹取装样柄,缓慢伸入三瓣模内,平放于泥膏顶面。⑩静置数秒装样柄自然脱落,用镊子将其取出。⑪迅速装入下一层泥膏,此时砂层仍处于冰冻状态,能够保持上下面平整。如此反复步骤②—⑩,实现粉质黏土与粉砂的互层装样。⑫在试样顶部放置滤纸和饱和透水石,在底座和顶端均加水保持水位,静置24 h。

2.2 试样预固结

为保证试样具有自立性,方便后续三轴试验装样,制样后对试样进行预固结,通过改装的固结仪实现:将原有固结仪两侧短杆更换成大于试样高度的长杆,并重新配备顶帽,如图4所示。试验发现,分三级(5,13.32,30 kPa)预固结至30 kPa能保证后续三轴仪装样成功。预固结完成后,取下三瓣模,切去多余的土样,制得尺寸51 mm(直径)×100 mm(高度)的重塑互层样,如图4所示。

3. 制样可重复性验证

3.1 试样均匀性验证

沿纵向切开试样侧面,剖面见图4,黏土层与砂层分布均匀,层间平行,预固结完成后,黏土层由原来的7 mm压缩为5 mm,砂层层厚基本保持不变,依然为4 mm,薄层与厚层比值为0.8,满足互层土的定义,试样制备效果较好。用烘干法测定互层土整体含水率,三次平行试样的含水率分别为33.51%、33.85%、33.41%,差别较小,表明制样方法可靠。

为确定沿试样高度方向是否均匀,对各黏土层进行密度测定。由于互层土中黏土层较薄,无法用常规方法测定其密度,特制内径为40 mm、高度为3.5 mm的小环刀。为保证小环刀的准确性,对同一纯粉质黏土试样分别进行标准环刀(内径61.8 mm、高度20 mm)与小环刀进行密度测定,发现小环刀密度测定结果与标准环刀测定结果差值在0.03 g·cm-3以内,说明小环刀测定密度方法可行。小环刀测得的互层样中各黏土层湿密度的样本标准差为0.018 g·cm-3,表明试样沿高度方向均匀性能够保证。

3.2 试样三轴剪切相应可重复性验证

采用应变控制式静力三轴系统对两个相同条件下制备的重塑互层土的静力特性进行比较。两组试样均在100 kPa有效固结围压下进行等向固结不排水三轴剪切试验,试验剪切速率为0.1%/min,剪切应变达到20%左右结束试验。

图5(a)为两互层样的应力应变曲线。由图5(a)可见,随着轴向应变增加,互层样的偏应力逐渐上升,且轴向应变约为15%时出现峰值。两组试样在相同有效围压下应力-应变结果接近。峰值后由于两个试样的破坏细节有所差异,故应力应变曲线差别明显。图5(b)为孔压发展曲线,随着轴向应变的增加,孔隙水压力升高,并且都在轴向应变约为3%时达到峰值,达到峰值后又有所减小。两试样的孔压曲线接近。图5(c)为有效应力路径对比,两试样结果一致性好。

通过上述分析可知,通过本方法制备的重塑互层样能够满足静力试验,且具有良好的重复性,所得试验规律性良好,可以用来进行互层土力学特性的系统研究。

4. 结论

本文系统介绍了一种粉质黏土-粉砂互层土的制样装置与使用方法。使用砂层模具冷冻砂层能够保证在制样时控制砂层与黏土层层间平行,透明三瓣模能够在制样时方便观测制样效果且便于控制层高。预固结能够模拟互层土沉积—固结的自然形成过程,保证砂层与黏土层良好接触,避免了简单叠置土层导致的硬性层间分割,使得试样具有良好的整体性。测试了所制备试样内部的湿密度分布,对比了平行试样的含水率和固结不排水三轴剪切试验结果,均表明本文提出的方法可以制备出均匀、重复性好的重塑互层土样。

该制样方法合理可靠、操作性强,填补了黏性土与砂性土互层情形的互层土制样方法,可用于该类互层土静、动力学特性的系统研究。

-

表 1 工程特性指标变化率

Table 1 Change rates of geotechnical property indexes

工程特性参数 污染区土样 修复区土样 含水率 0.74* 79.91*** 密度 1.99* 8.79* 相对质量密度 < 0.01* 0.74* 干密度 1.92* 22.08** 孔隙比 4.06* 65.42*** 液限 0.06* 57.89*** 塑限 0.48* 55.24*** 塑性指数 0.59* 60.51*** 压缩系数 8.99* 128.57*** 水平渗透系数 28.49** 91.43*** 垂向渗透系数 21.78** 91.14*** 注:*为影响轻微,**为影响中等,***为影响大。 -

[1] 中华人们共和国国务院. 长江经济带发展规划纲要[R]. 2016. The State Council, The People's Republic of China. Outline of Yangtze River Economic Belt Development Plan[R]. 2016. (in Chinese)

[2] QU C S, WANG S, ENGELUND H P. China: Soil clean-up needs cash and clarity[J]. Nature, 2016, 538(7625): 371.

[3] ZHOU Y, LIU Y S. China's fight against soil pollution[J]. Science, 2018, 362(6412): 298. doi: 10.1126/science.aav4061

[4] HOANG S A, SARKAR B, SESHADRI B, et al. Mitigation of petroleum-hydrocarbon-contaminated hazardous soils using organic amendments: a review[J]. Journal of Hazardous Materials, 2021, 416: 125702. doi: 10.1016/j.jhazmat.2021.125702

[5] QUIGLEY R M, FERNANDEZ F, YANFUL E, et al. Hydraulic conductivity of contaminated natural clay directly below a domestic landfill[J]. Canadian Geotechnical Journal, 1987, 24(3): 377-383. doi: 10.1139/t87-048

[6] NAYAK S, SUNIL B M, SHRIHARI S. Hydraulic and compaction characteristics of leachate-contaminated lateritic soil[J]. Engineering Geology, 2007, 94(3/4): 137-144.

[7] KHAMEHCHIYAN M, HOSSEIN C A, TAJIK M. Effects of crude oil contamination on geotechnical properties of clayey and sandy soils[J]. Engineering Geology, 2007, 89(3/4): 220-229.

[8] XU P P, ZHANG Q Y, QIAN H, et al. Investigating the mechanism of pH effect on saturated permeability of remolded loess[J]. Engineering Geology, 2021, 284: 105978. doi: 10.1016/j.enggeo.2020.105978

[9] DU Y J, JIANG N J, LIU S Y, et al. Engineering properties and microstructural characteristics of cement-stabilized zinc-contaminated Kaolin[J]. Canadian Geotechnical Journal, 2014, 51(3): 289-302. doi: 10.1139/cgj-2013-0177

[10] FURMAN O S, TEEL A L, WATTS R J. Mechanism of base activation of persulfate[J]. Environmental Science & Technology, 2010, 44(16): 6423-6428.

[11] LOMINCHAR M A, SANTOS A, DE MIGUEL E, et al. Remediation of aged diesel contaminated soil by alkaline activated persulfate[J]. Science of the Total Environment, 2018, 622/623: 41-48. doi: 10.1016/j.scitotenv.2017.11.263

[12] LI Y T, ZHANG J J, LI Y H, et al. Treatment of soil contaminated with petroleum hydrocarbons using activated persulfate oxidation, ultrasound, and heat: A kinetic and thermodynamic study[J]. Chemical Engineering Journal, 2021, 428(3/4): 131336.

[13] CHEN Y Z, ZHOU W H, LIU F M, et al. Exploring the effects of nanoscale zero-valent iron (nZVI) on the mechanical properties of lead-contaminated clay[J]. Canadian Geotechnical Journal, 2019, 56(10): 1395-1405. doi: 10.1139/cgj-2018-0387

[14] POLLI F, ZINGARETTI D, CROGNALE S, et al. Impact of the Fenton-like treatment on the microbial community of a diesel-contaminated soil[J]. Chemosphere, 2018, 191: 580-588. doi: 10.1016/j.chemosphere.2017.10.081

[15] CHEN L W, HU X X, CAI T M, et al. Degradation of Triclosan in soils by thermally activated persulfate under conditions representative of in situ chemical oxidation (ISCO)[J]. Chemical Engineering Journal, 2019, 369: 344-352. doi: 10.1016/j.cej.2019.03.084

[16] 高彦斌, 刘佳丹, 王雨滢. 酸碱污染重塑粉质黏土的塑性及其与力学特性的关系[J]. 岩土工程学报, 2018, 40(11): 2103-2109. doi: 10.11779/CJGE201811017 GAO Yanbin, LIU Jiadan, WANG Yuying. Plasticity and its relationship with mechanical properties of a remolded silty clay contaminated by several acids and bases[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(11): 2103-2109. (in Chinese) doi: 10.11779/CJGE201811017

[17] MITCHELL J K, SOGA K. Fundamentals of soil behavior[M]. 3rd ed. Hoboken, NJ: John Wiley & Sons, 2005.

[18] CHANEY R C, DEMARS K R, SRIDHARAN A, et al. Percussion and cone methods of determining the liquid limit of soils: controlling mechanisms[J]. Geotechnical Testing Journal, 2000, 23(2): 236. doi: 10.1520/GTJ11048J

[19] GAJO A, MAINES M. Mechanical effects of aqueous solutions of inorganic acids and bases on a natural active clay[J]. Géotechnique, 2007, 57(8): 687-699. doi: 10.1680/geot.2007.57.8.687

[20] CROCE P, FLORA A. Analysis of single-fluid jet grouting[J]. Géotechnique, 2000, 50(6): 739-748. doi: 10.1680/geot.2000.50.6.739

[21] CHAI J C, JIA R, HINO T. Anisotropic consolidation behavior of ariake clay from three different CRS tests[J]. Geotechnical Testing Journal, 2012, 35(6): 103848. doi: 10.1520/GTJ103848

[22] TERZAGHI K, PECK R B. Soil mechanics in engineering practice[M]. 2d ed. New York: Wiley, 1967.

[23] AZZOUZ A S, KRIZEK R J, COROTIS R B. Regression analysis of soil compressibility[J]. Soils and Foundations, 1976, 16(2): 19-29. doi: 10.3208/sandf1972.16.2_19

[24] YOON G L, KIM B T, JEON S S. Empirical correlations of compression index for marine clay from regression analysis[J]. Canadian Geotechnical Journal, 2004, 41(6): 1213-1221. doi: 10.1139/t04-057

[25] ZENG L L, HONG Z S, GAO Y F. Practical estimation of compression behaviour of dredged clays with three physical parameters[J]. Engineering Geology, 2017, 217: 102-109. doi: 10.1016/j.enggeo.2016.12.013

[26] CUISINIER O, AURIOL J C, LE BORGNE T, et al. Microstructure and hydraulic conductivity of a compacted lime-treated soil[J]. Engineering Geology, 2011, 123(3): 187-193. doi: 10.1016/j.enggeo.2011.07.010

[27] DENG Y F, YUE X B, LIU S Y, et al. Hydraulic conductivity of cement-stabilized marine clay with metakaolin and its correlation with pore size distribution[J]. Engineering Geology, 2015, 193: 146-152. doi: 10.1016/j.enggeo.2015.04.018

[28] REN X W, SANTAMARINA J C. The hydraulic conductivity of sediments: a pore size perspective[J]. Engineering Geology, 2018, 233: 48-54. doi: 10.1016/j.enggeo.2017.11.022

[29] YANG Y L, REDDY K R, DU Y J, et al. Short-term hydraulic conductivity and consolidation properties of soil-bentonite backfills exposed to CCR-impacted groundwater[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2018, 144(6): 04018025. doi: 10.1061/(ASCE)GT.1943-5606.0001877

[30] ZENG L, CAI Y Q, CUI Y, et al. Hydraulic conductivity of reconstituted clays based on intrinsic compression[J]. Géotechnique, 2020, 70(3): 268–275. doi: 10.1680/jgeot.18.P.096

[31] DENG Y F, LIU L, CUI Y J, et al. Colloid effect on clogging mechanism of hydraulic reclamation mud improved by vacuum preloading[J]. Canadian Geotechnical Journal, 2019, 56(5): 611-620. doi: 10.1139/cgj-2017-0635

[32] INDRARATNA B, REDANA I W. Plane-strain modeling of smear effects associated with vertical drains[J]. Journal of Geotechnical and Geoenvironmental Engineering, 1997, 123(5): 474-478. doi: 10.1061/(ASCE)1090-0241(1997)123:5(474)

[33] XIE P C, GUO Y Z, CHEN Y Q, et al. Application of a novel advanced oxidation process using sulfite and zero-valent iron in treatment of organic pollutants[J]. Chemical Engineering Journal, 2017, 314: 240-248. doi: 10.1016/j.cej.2016.12.094

[34] CHEN Y Q, TONG Y, LIU Z Z, et al. Enhanced degradation of Orange II using a novel UV/persulfate/sulfite system[J]. Environmental Chemistry Letters, 2019, 17(3): 1435-1439. doi: 10.1007/s10311-019-00880-2

下载:

下载: