Observed deformation behavior of Gongbei Tunnel of Hong Kong-Zhuhai-Macao Bridge during construction

-

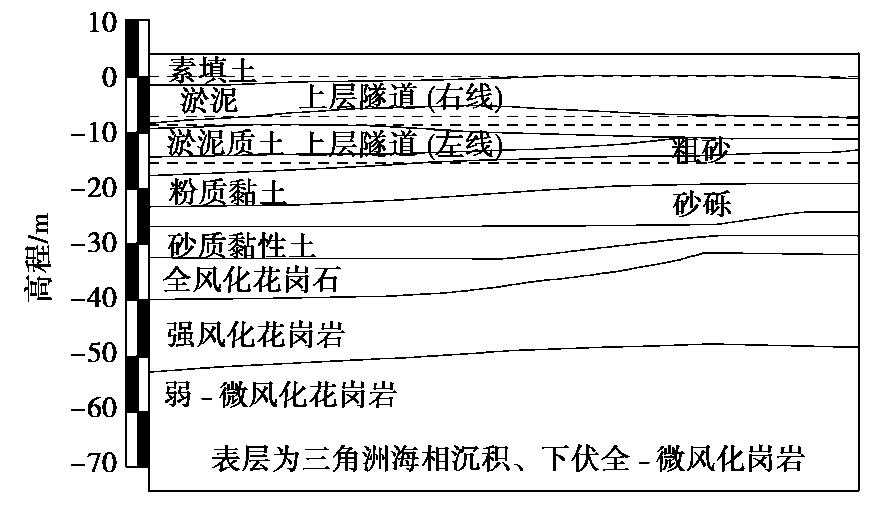

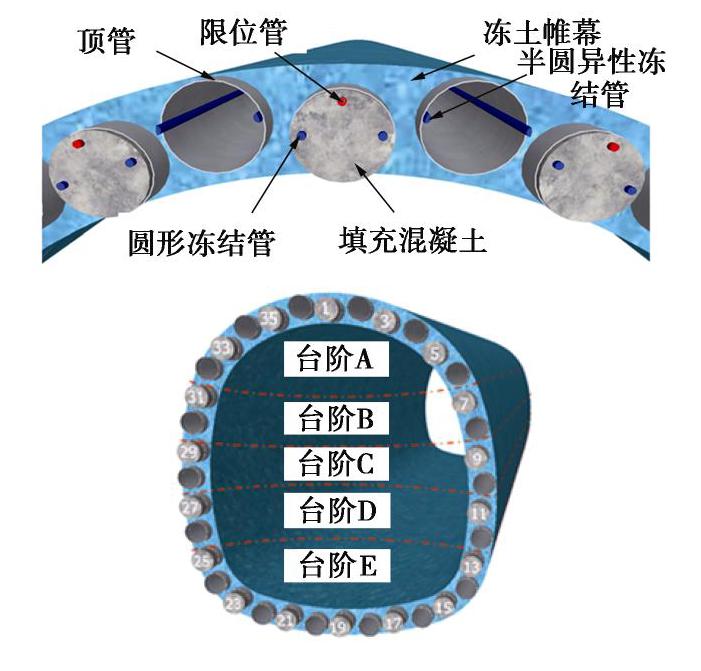

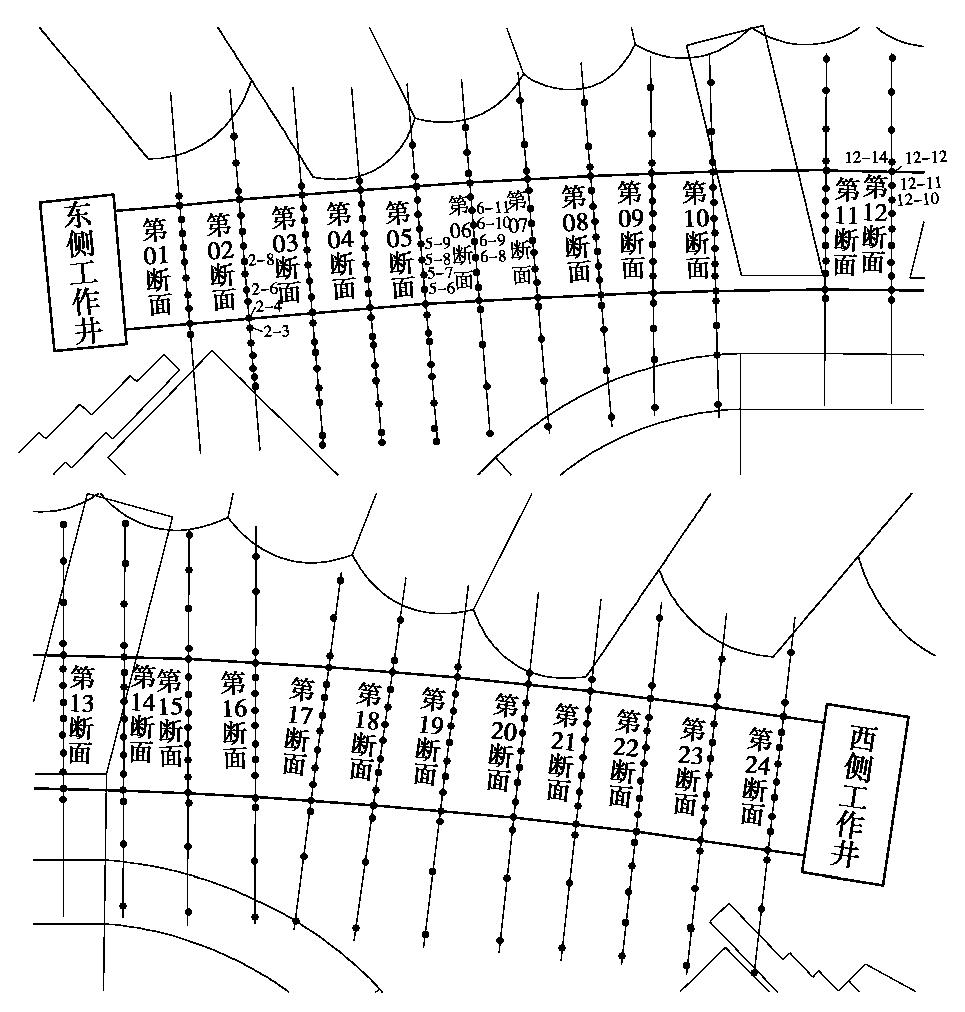

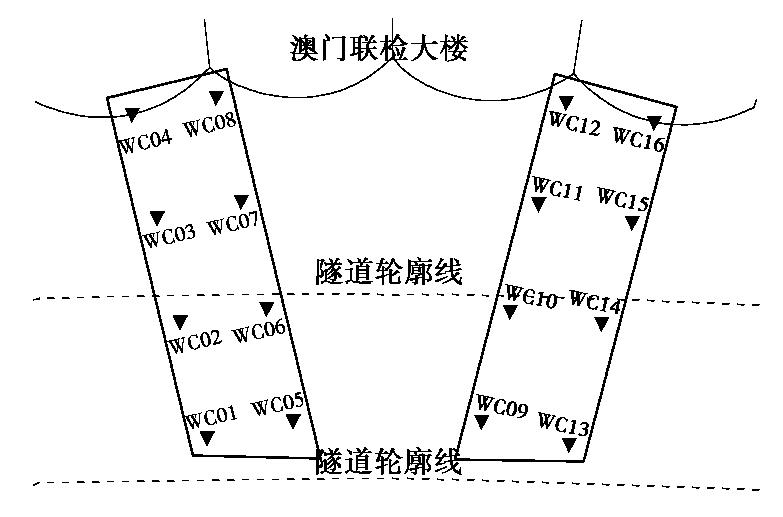

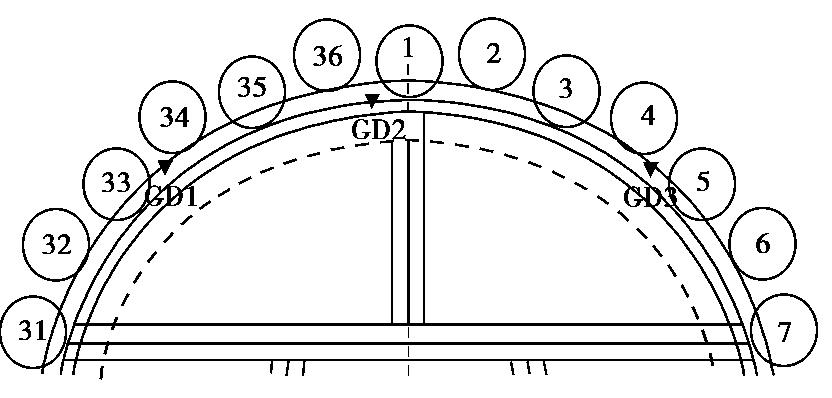

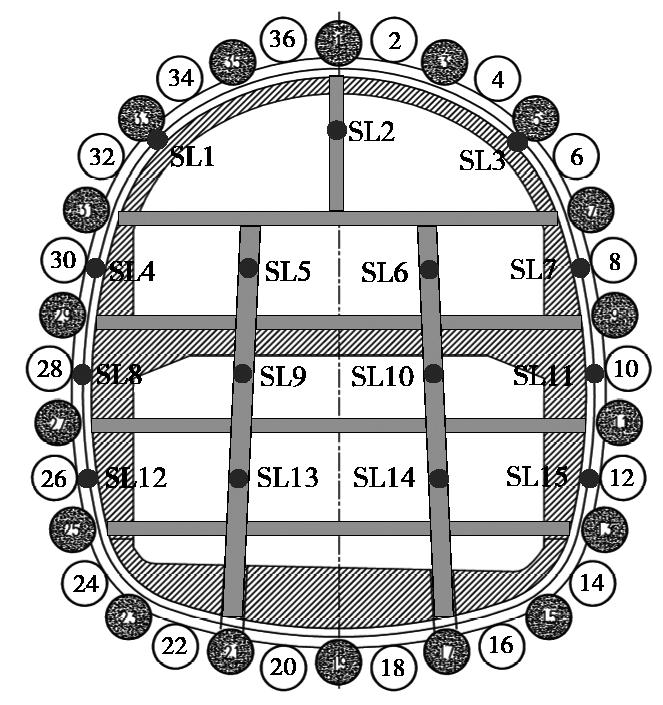

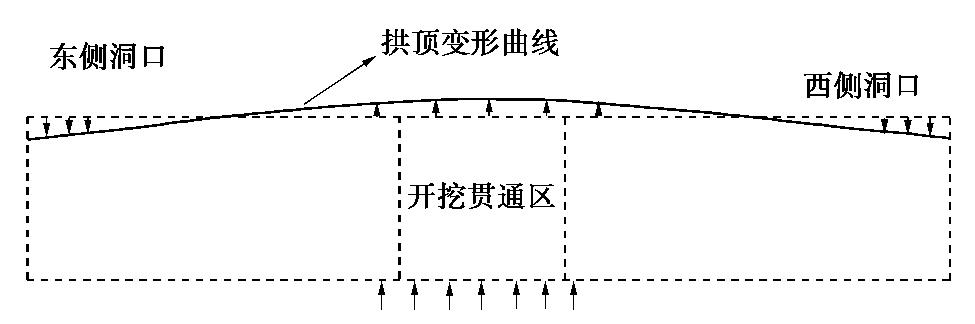

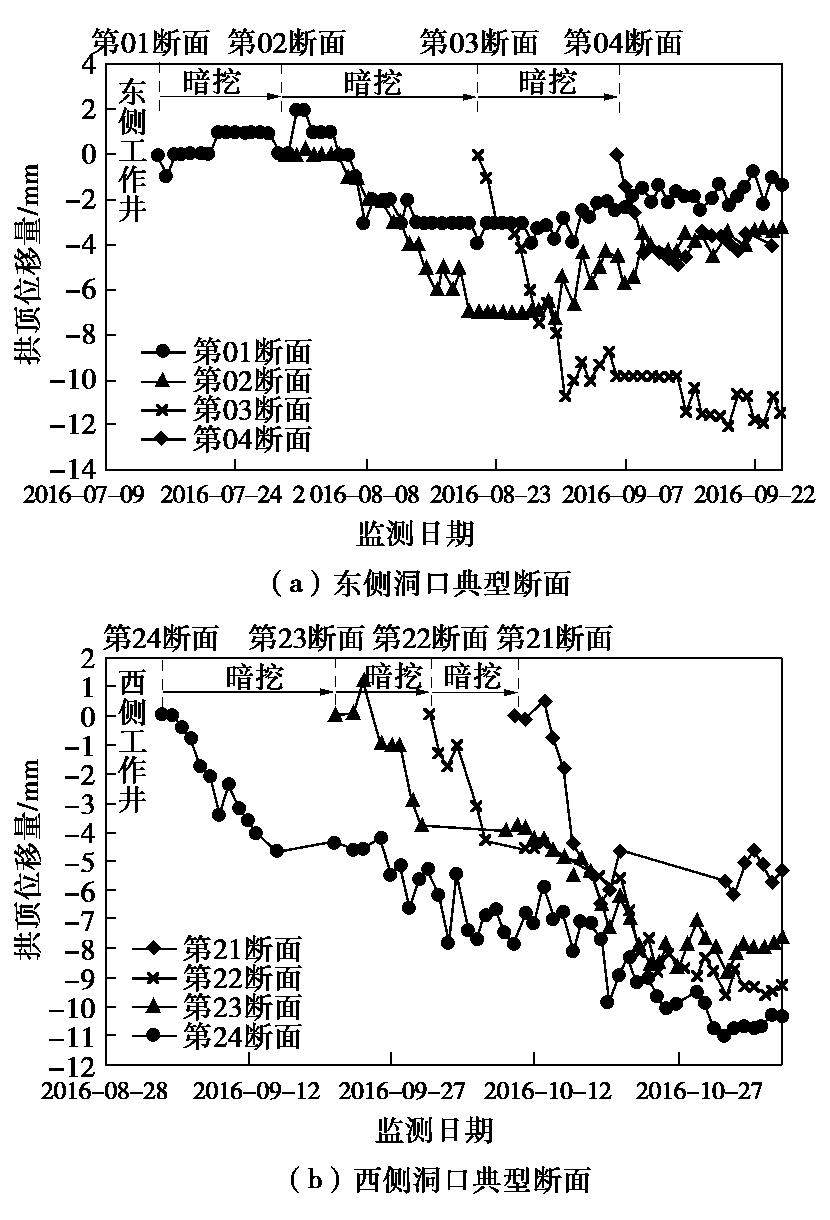

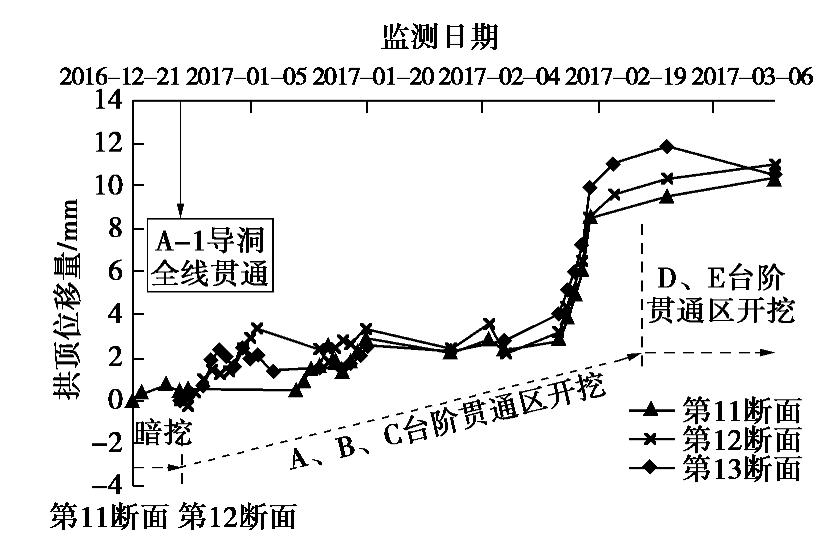

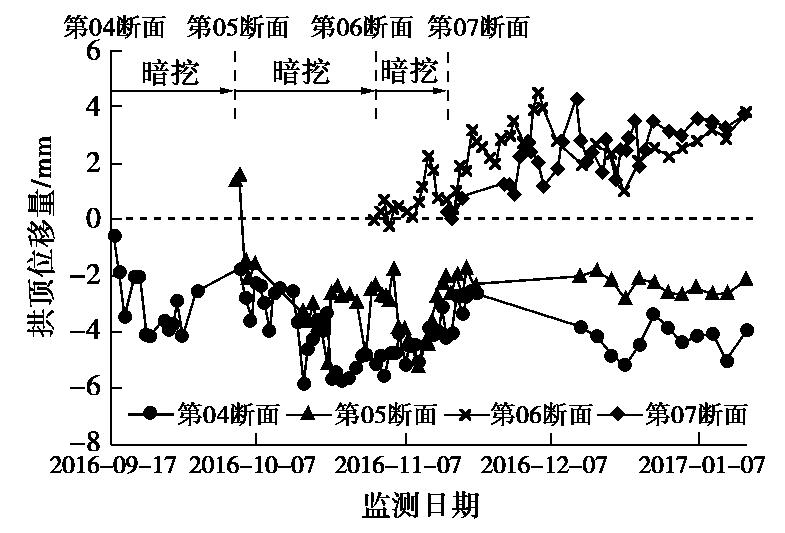

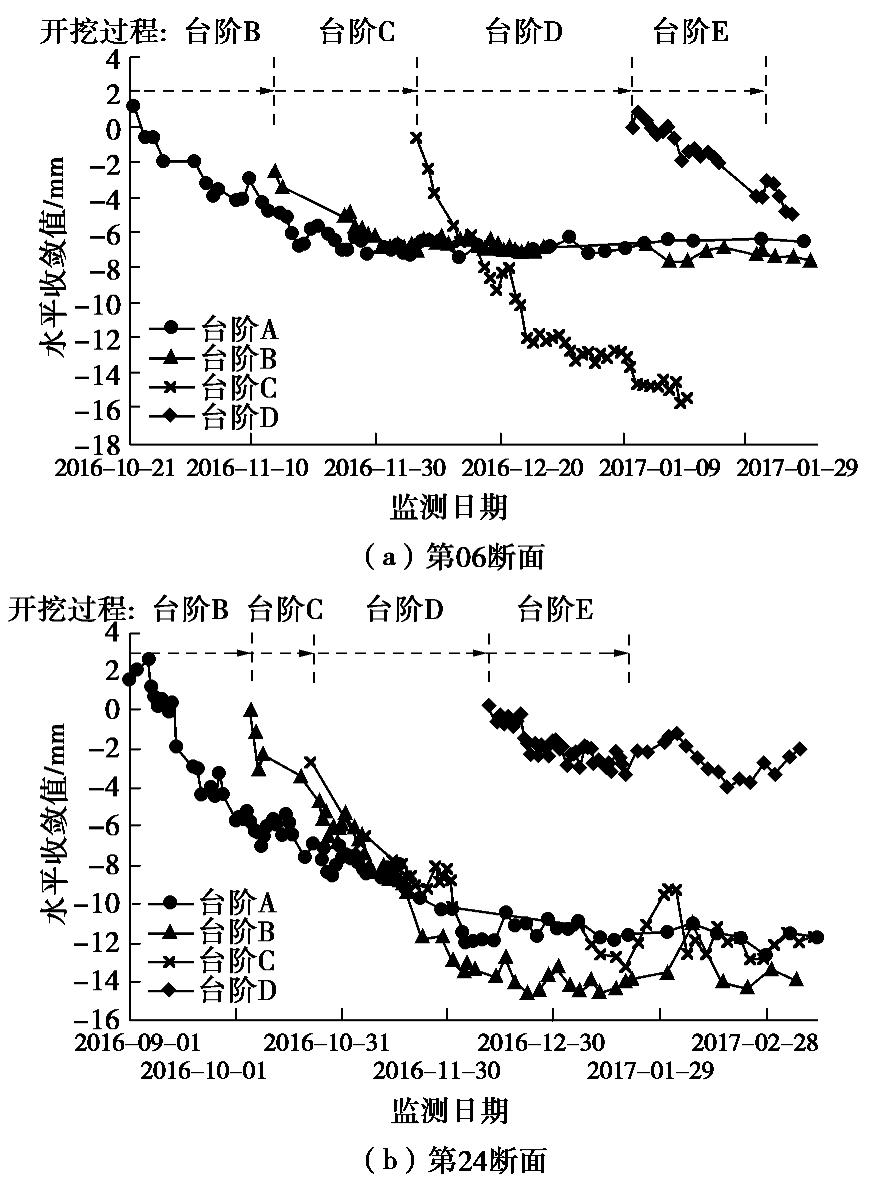

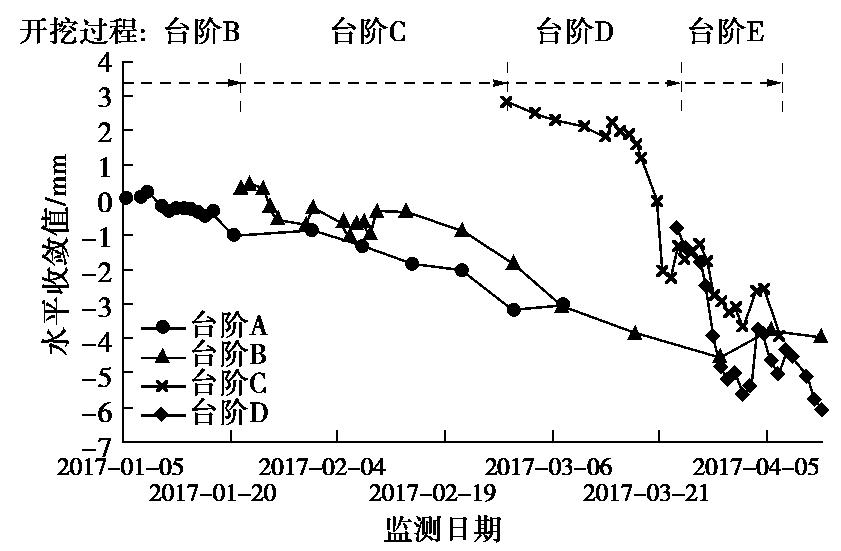

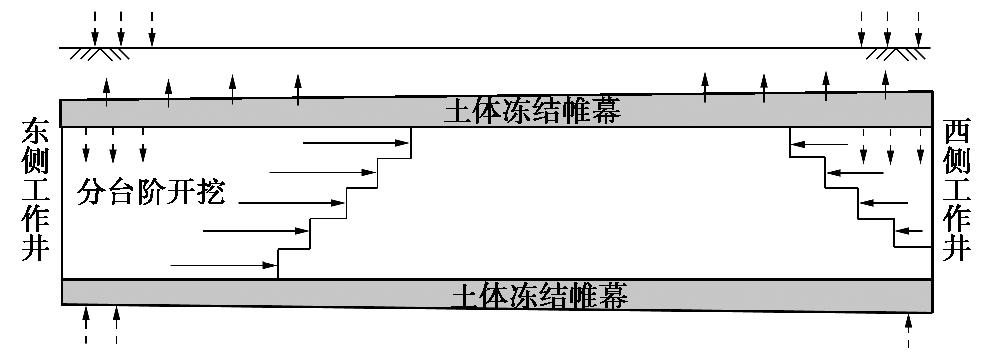

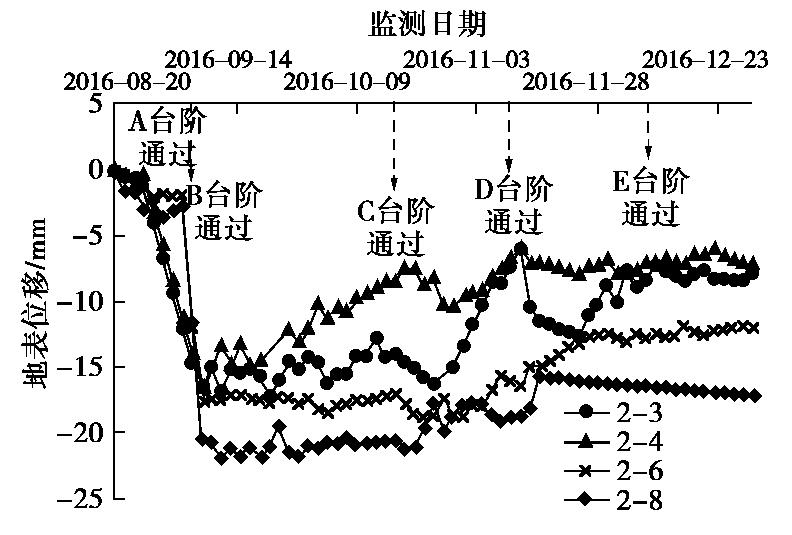

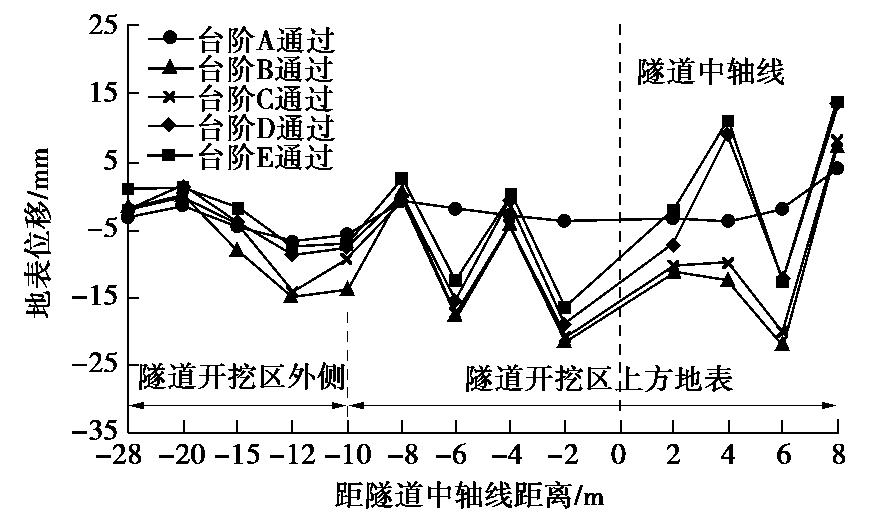

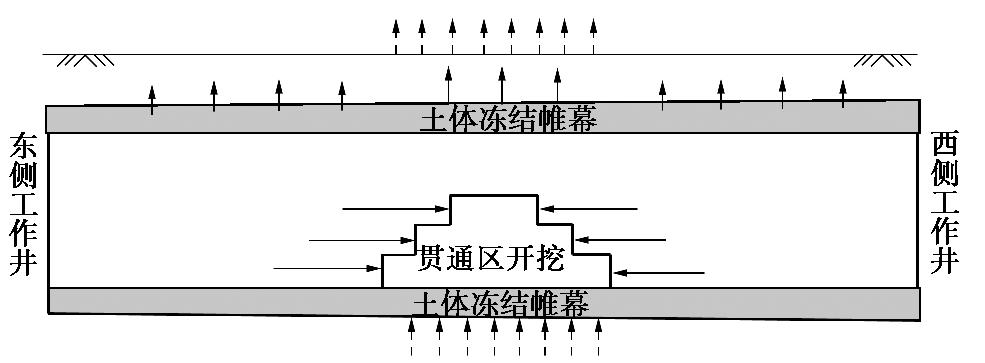

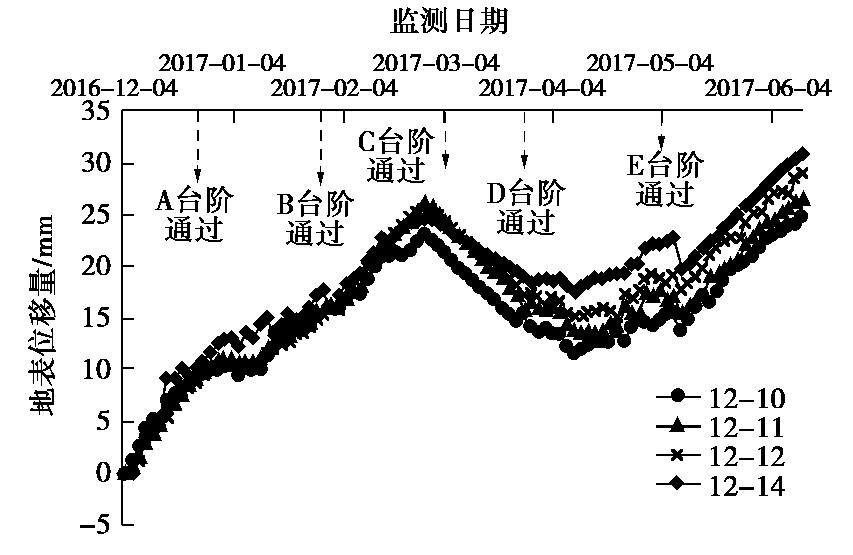

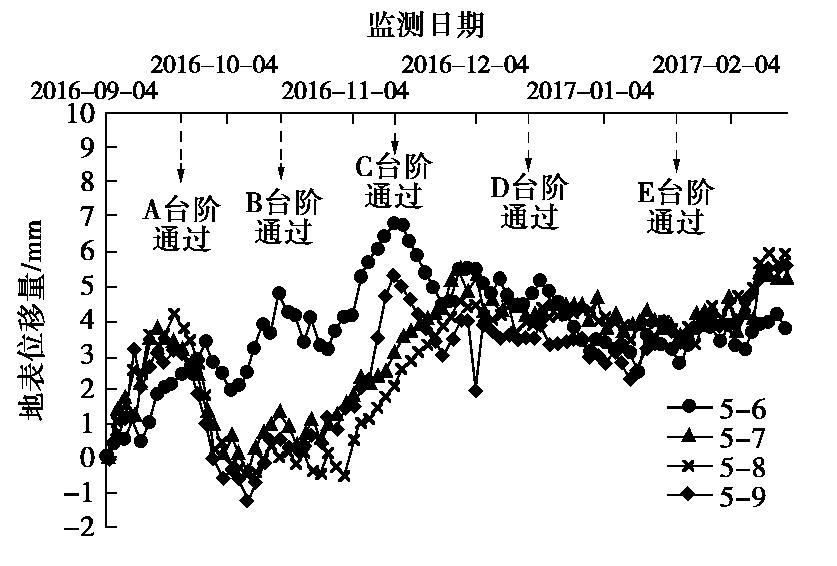

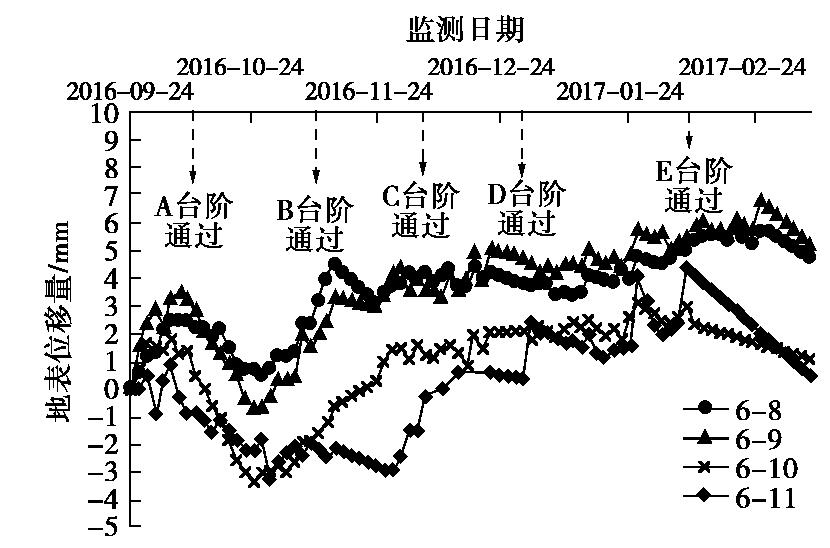

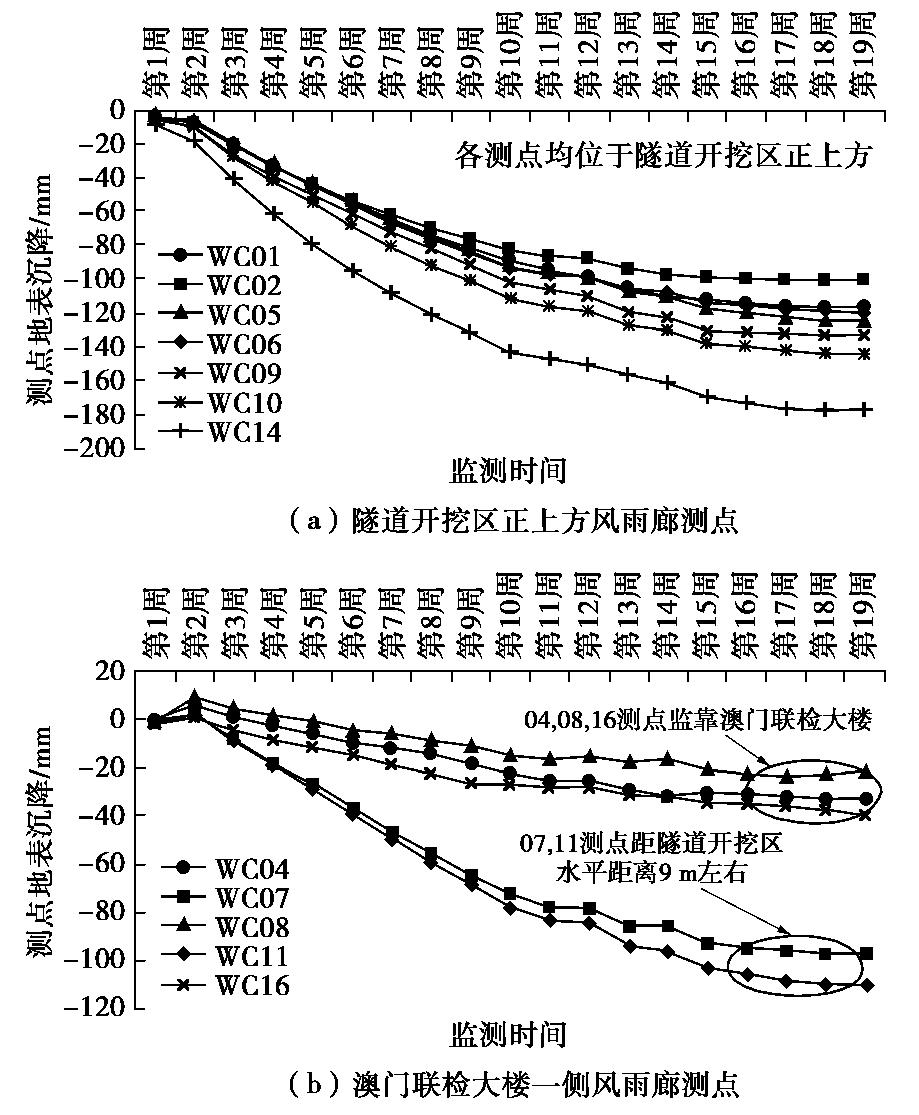

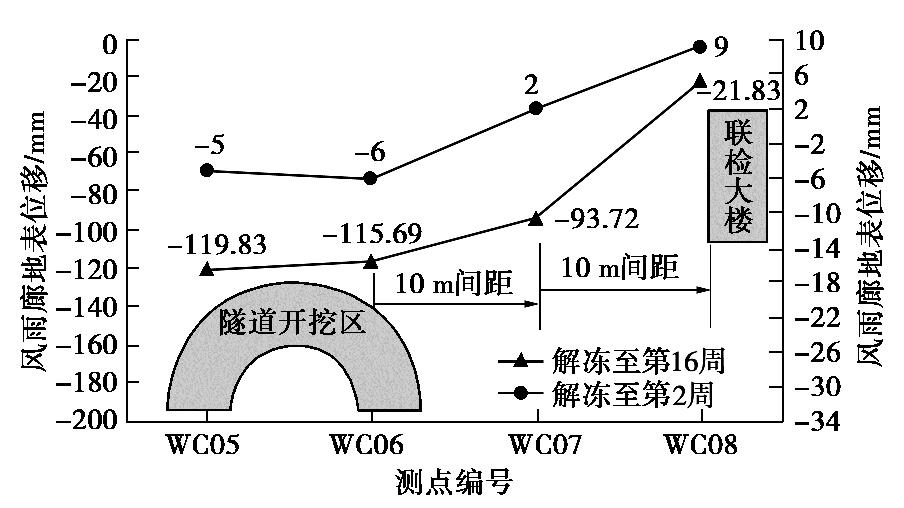

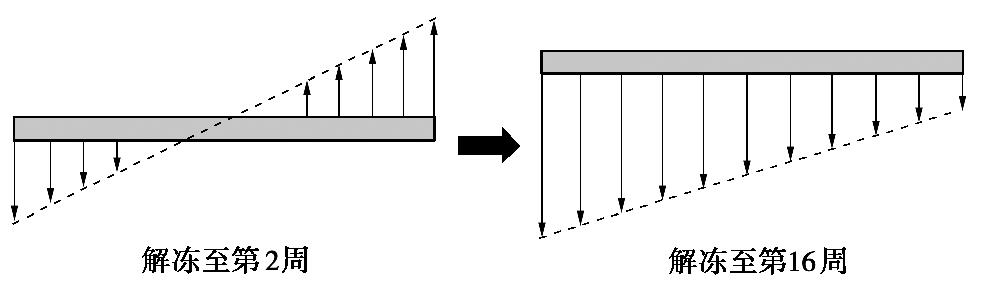

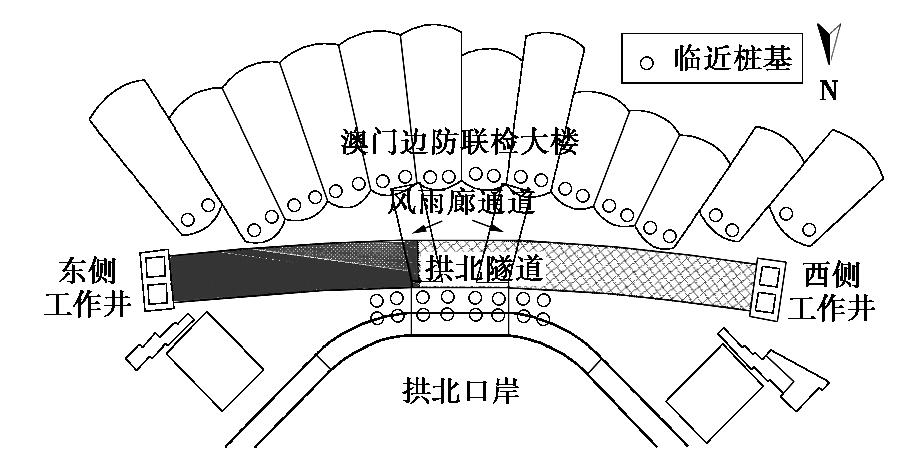

摘要: 在地质条件复杂的沿海富水地层开挖浅埋超大断面隧道,面临诸多风险,暗挖施工易对围岩进行扰动,引起地层变形。新型“管幕冻结”支护可以有效控制暗挖施工引起的地表沉降过大问题,该工法下隧道开挖过程中地表位移变化主要受暗挖产生的地层损失和土体冻结膨胀以及隧道开挖卸荷后的上浮效应等因素影响。基于现场实测数据,对洞内拱顶位移、水平收敛和地表变形规律进行分析发现,拱顶位移与对应地表处的位移变化具有较强的一致性,纵向上在隧道中部段出现上浮,两侧洞口段出现下沉。受分层开挖扰动影响,隧道两侧土体向内变形导致洞内水平收敛增大,最大水平收敛为15.72 mm,约为隧道横向跨度的0.8%。新型管幕冻结暗挖施工工法可以很好地控制富水地层渗漏水问题,且极大地减小了隧道内部的位移变形,但其冻结膨胀引起地表隆起及解冻后的地表融沉问题仍需密切关注。Abstract: The excavation of shallow buried tunnels with super-large section in coastal water-rich strata with complex geological conditions faces a lot of risks. The surrounding soil is easy to be disturbed during excavation, causing the ground deformation. The new method of "freezing-sealing pipe-roof for pre-support" can effectively control the surface settlement caused by the excavation construction. The change of surface displacement during tunnel excavation using this method is mainly affected by the factors such as the ground loss caused by tunnel excavation, expansion of frozen soil and floating effect after tunnel excavation unloading. The rules of tunnel crown displacement, horizontal convergence and ground deformation are investigated based on the in-situ observation. The displacements of the tunnel crown and the corresponding surface are consistent. In the longitudinal direction, the crown and ground surface move up in the middle section and move down in the sections at both sides near the working shafts. Under the influence of layered excavation disturbance, the inward deformation of the soil at both sides of the tunnel leads to the increase of horizontal convergence, and the maximum horizontal convergence is 15.72 mm, which is about 0.8% of the transverse span of the tunnel. The new freezing-sealing pipe-roof method can solve the problem of water leakage in the water-rich strata, and greatly reduce the internal deformation of the tunnel. However, the problem of surface heaving caused by soil freezing and the surface settlement after soil thawing still require great attention.

-

-

表 1 两侧洞口段拱顶和对应地表处位移对比表

Table 1 Displacements of crown and corresponding surface

位置 断面号 最大拱顶位移/mm 最大地表位移/mm 东侧洞口 第02断面 -7.3(下沉) -21.8(沉降) 西侧洞口 第23断面 -8.8(下沉) -29.6(沉降) 表 2 隧道中部段拱顶和对应地表处位移对比表

Table 2 Displacements of crown and corresponding surface

位置 断面号 最大拱顶位移/mm 最大地表位移/mm 风雨廊通道区域内 第12断面 11.0(上移) 25.5(隆起) 第14断面 10.8(上移) 28.0(隆起) 风雨廊通道区域外 第16断面 5.5(上移) 62.9(隆起) -

[1] 黄俊, 张顶立. 地铁暗挖隧道上覆地层大变形规律分析[J]. 岩土力学, 2004(8): 1288-1292, 1301. doi: 10.3969/j.issn.1000-7598.2004.08.024 HUANG Jun, ZHANG Ding-li. Analysis of large deformation regularity in stratum above metro tunnel[J]. Rock & Soil Mechanics, 2004(8): 1288-1292, 1301. (in Chinese) doi: 10.3969/j.issn.1000-7598.2004.08.024

[2] VAHEDIFARD F L D, MEEHAN C L. Displacement-based internal design of geosynthetic-reinforced earth structures subjected to seismic loading conditions[J]. Géotechnique, 2013, 63: 451-462. doi: 10.1680/geot.11.P.130

[3] 张成平, 张顶立, 王梦恕, 等. 城市隧道施工诱发的地面塌陷灾变机制及其控制[J]. 岩土力学, 2010, 31(增刊1): 303-309. doi: 10.16285/j.rsm.2010.s1.041 ZHANG Cheng-ping, ZHANG Ding-li, WANG Meng-shu, et al. Catastrophe mechanism and control technology of ground collapse induced by urban tunneling[J]. Rock & Soil Mechanics, 2010, 31(S1): 303-309. (in Chinese) doi: 10.16285/j.rsm.2010.s1.041

[4] MUSSO G. Jacked pipe provides roof for underground construction in busy urban area[J]. Civil Engineering, 1979, 49(11): 79-82.

[5] 陈湘生. 冻结法几个关键问题及在地下空间近接工程中最新应用[J]. 隧道建设, 2015, 35(12): 1243-1251. doi: 10.3973/j.issn.1672-741X.2015.12.002 CHEN Xiang-sheng. Several key points of artificial ground freezing method and its latest application in China[J]. Tunnel Construction, 2015, 35(12): 1243-1251. (in Chinese) doi: 10.3973/j.issn.1672-741X.2015.12.002

[6] LIU J G, MA B S, CHENG Y. Design of the Gongbei tunnel using a very large cross-section pipe-roof and soil freezing method[J]. Tunnelling & Underground Space Technology, 2018, 72: 28-40.

[7] ZHANG P, MA B S, ZENG C, et al. Key techniques for the largest curved pipe jacking roof to date: a case study of Gongbei tunnel[J]. Tunnelling & Underground Space Technology, 2016, 59: 134-145.

[8] 陶德敬, 王明年, 刘大刚. 冻结法隧道施工引起的地表移动及变形预测[J]. 现代隧道技术, 2006, 43(6): 45-50. doi: 10.3969/j.issn.1009-6582.2006.06.009 TAO De-jing, WANG Ming-nian, LIU Da-gang. Prediction of surface movement and deformation caused by the freezing method construction of tunnels[J]. Modern Tunnelling Technology, 2006, 43(6): 45-50. (in Chinese) doi: 10.3969/j.issn.1009-6582.2006.06.009

[9] 肖世国, 夏才初, 朱合华, 等. 管幕内箱涵顶进中顶部管幕竖向变形预测[J]. 岩石力学与工程学报, 2006, 25(9): 1887-1892. doi: 10.3321/j.issn:1000-6915.2006.09.023 XIAO Shi-guo, XIA Cai-chu, ZHU He-hua, et al. Vertical deformation prediction on upper pipe-roof during a box culvert being pushed within a pipe-roof[J]. Chinese Journal of Rock Mechanics & Engineering, 2006, 25(9): 1887-1892. (in Chinese) doi: 10.3321/j.issn:1000-6915.2006.09.023

[10] 朱合华, 闫治国, 李向阳, 等. 饱和软土地层中管幕法隧道施工风险分析[J]. 岩石力学与工程学报, 2005, 24(增刊2): 5549-5554. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2005S2050.htm ZHU He-hua, YAN Zhi-guo, LI Xiang-yang, et al. Analysis of construction risks for pipe-roofing tunnel in saturated soft soil[J]. Chinese Journal of Rock Mechanics & Engineering, 2005, 24(S2): 5549-5554. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2005S2050.htm

[11] 胡向东, 邓声君, 汪洋. 拱北隧道“钢管–冻土”复合结构承载力试验研究[J]. 岩土工程学报, 2018, 40(8): 1481-1490. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201808017.htm HU Xiang-dong, DENG Sheng-jun, WANG Yang. Mechanical tests on bearing capacity of steel pipe-frozen soil composite structure applied in Gongbei Tunnel[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(8): 1481-1490. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201808017.htm

[12] 任辉, 胡向东, 洪泽群, 等. 超浅埋暗挖隧道管幕冻结法积极冻结方案试验研究[J]. 岩土工程学报, 2019, 41(2): 131-139. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201902011.htm REN Hui, HU Xiang-dong, HONG Ze-qun, et al. Experimental study on active freezing scheme of freeze-sealing pipe roof used in ultra-shallow buried tunnels[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(2): 131-139. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201902011.htm

[13] 胡向东, 李忻轶, 吴元昊, 等. 拱北隧道管幕冻结法管间冻结封水效果实测研究[J]. 岩土工程学报, 2019, 41(12): 2207-2214. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201912008.htm HU Xiang-dong, LI Xin-yi, WU Yuan-hao, et al. Effect of water-proofing in Gongbei Tunnel by freeze-sealing pipe roof method with field temperature data[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(12): 2207-2214. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201912008.htm

[14] 熊昊翔, 任辉, 翁远林. 拱北隧道5台阶14部开挖施工组织方案分析[J]. 隧道建设, 2019, 39(2): 281-286. https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201902024.htm XIONG Hao-xiang, REN Hui, WENG Yuan-lin. Analysis of construction organization scheme of five-bench fourteenstep excavation applied to Gongbei Tunnel[J]. Tunnel Construction, 2019, 39(2): 281-286. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201902024.htm

下载:

下载: