Difference in micro-properties and liquefaction of undisturbed loess in China and USA

-

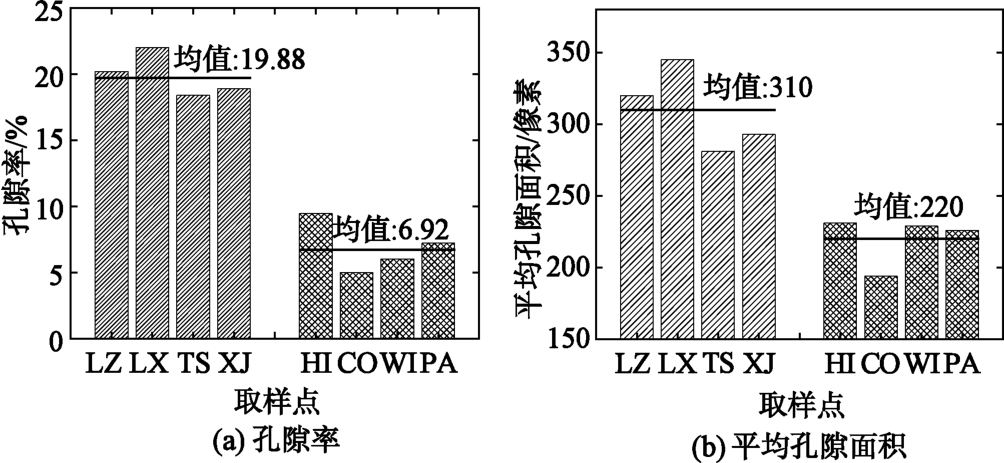

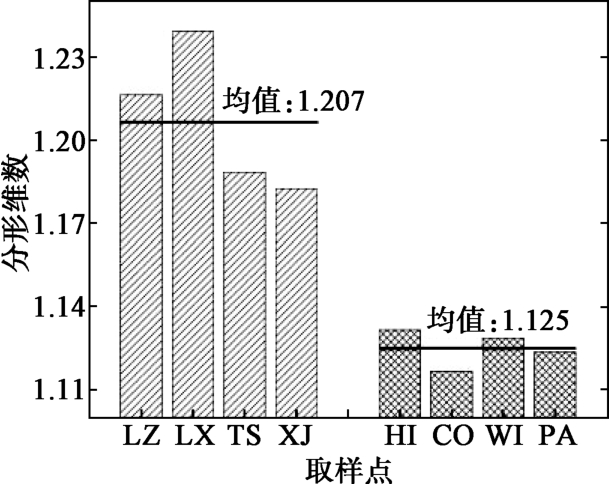

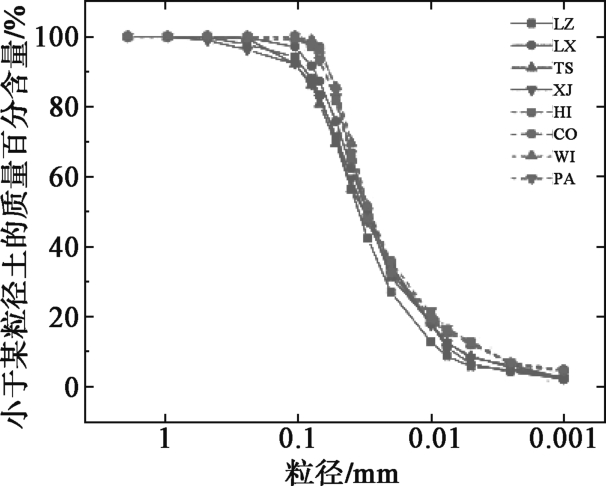

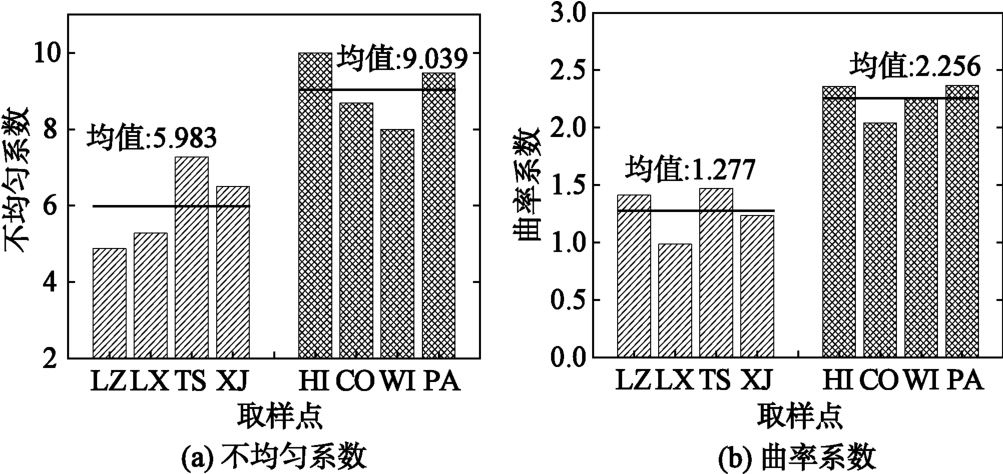

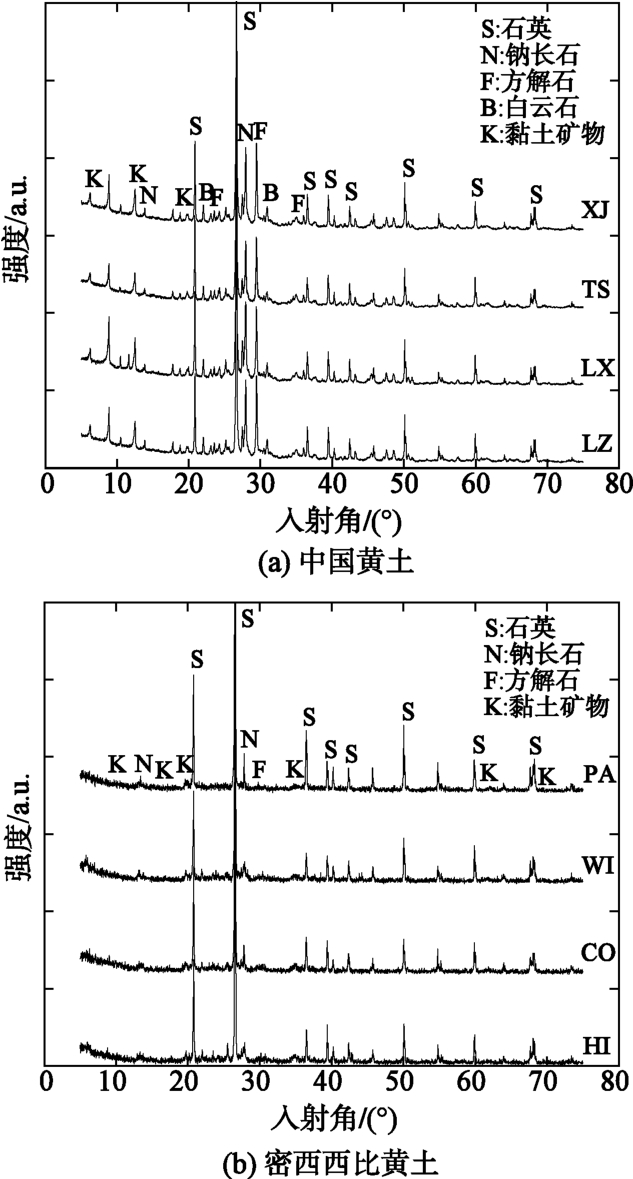

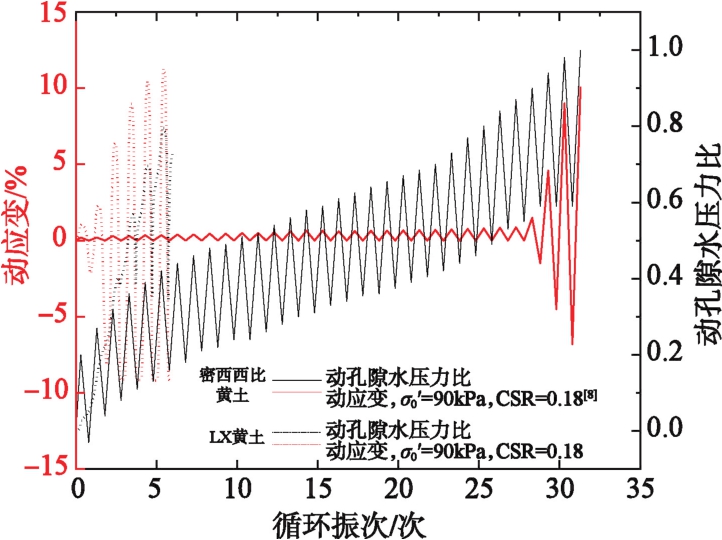

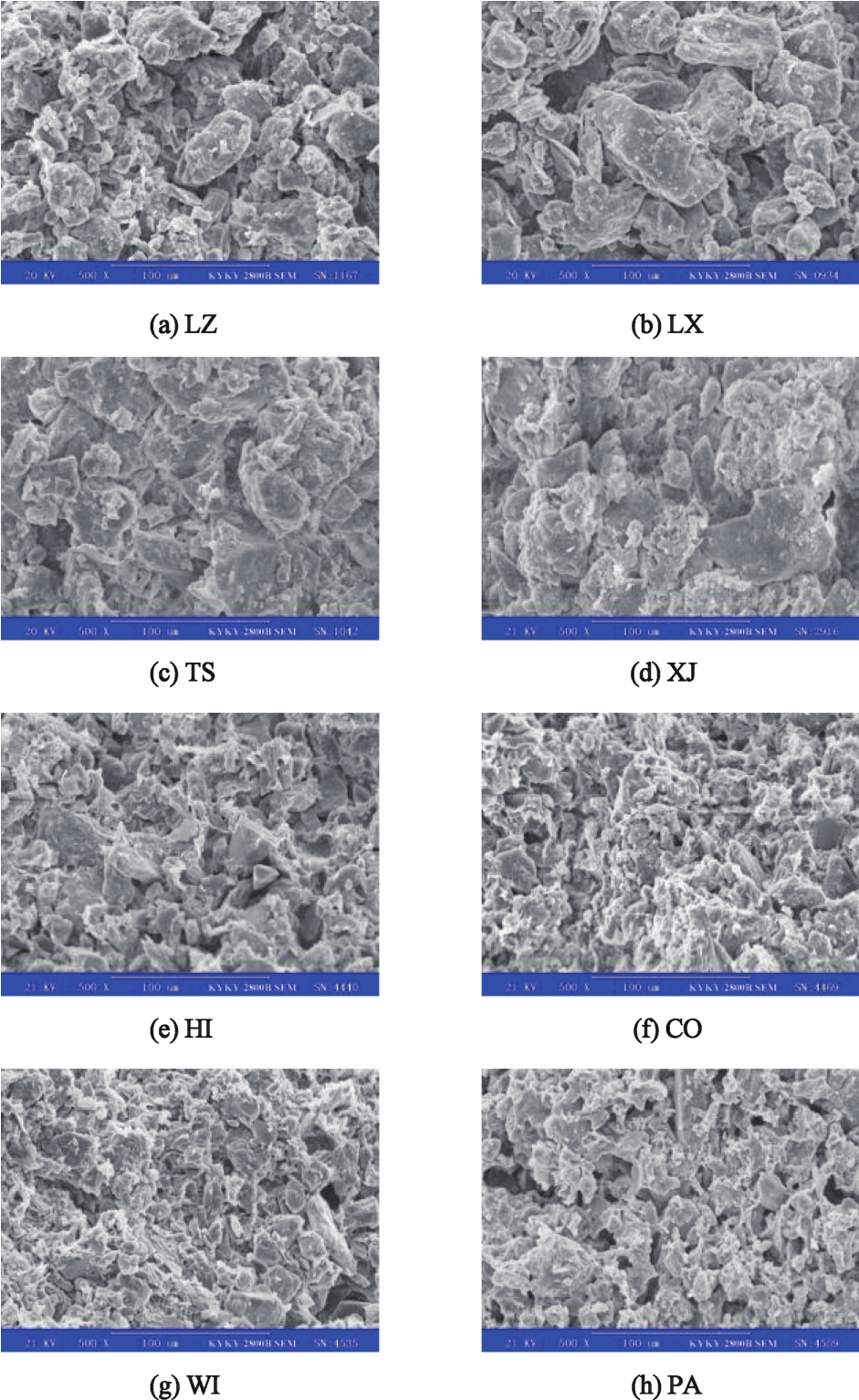

摘要: 中国黄土高原和美国密西西比河流域均发生了严重的黄土地震液化灾害。采用扫描电镜测试、颗粒分析试验和XRD矿物成分测试,研究了中、美黄土的微观特征差异性,并结合动三轴液化试验结果,分析了土体微观特征差异性对液化特性的影响,探讨了造成中、美黄土液化势差异的微观机理。研究结果表明:相较于中国黄土,密西西比黄土的颗粒间以面接触为主,胶结物更多,孔隙尺度更小,孔隙率、平均孔隙面积和分形维数均较小,土体中不含白云石,且黏土矿物含量较多,粒径级配更优,孔隙排列更为整齐,土骨架结构强度更大,使得其具有较为优良的动力稳定性。微观特征差异是导致中、美黄土液化特性存在差别的主要内因,相比于中国黄土,密西西比黄土结构强度、比表面积和亲水矿物含量均较大,使得其动应变增长较为缓慢,抑制动孔隙水压力发展的能力更优,抗液化能力更强。Abstract: Both the Loess Plateau(LP)in China and the Mississippi River Valley(MRV)in the USA have serious loess liquefaction disasters triggered by strong earthquakes.However, the liquefaction characteristics in the two regions are different.To analyze the difference in the micro-characteristics including the microstructure, particle size and mineral composition of the undisturbed loess sampled from the LP and the MRV, a series of scanning electron microscope tests, grain size analysis and X-ray diffraction tests are conducted.Besides, the difference in liquefaction behaviors between the loess in the two regions is discussed based on the dynamic triaxial tests.The results show that compared with the LP loess, the MRV loess has more cement, smaller pore sizes, more clay particles and clay minerals, which forms a typical clotted cementation structure among the particles.The porosity, the average pore area and the fractal dimension of the MRV loess are significantly lower than those of the LP loess, causing that the liquefaction resistance of the MRV loess is significantly stronger.The differences of microcharacteristics are the main internal reason for the differences in liquefaction characteristics between the LP loess and the MRV loess.Compared with those of the LP loess, the structural strength, the specific surface area and the hydrophilic mineral content of the MRV loess are larger, which makes the dynamic strain growth be slower and the ability to restrain the development of dynamic pore water pressure be better.

-

Keywords:

- Loess Plateau /

- Mississippi River /

- liquefaction /

- SEM /

- grain size /

- mineral composition

-

感谢国家留学基金会资助笔者在美国的学习和研究工作。

-

-

[1] 白铭学, 张苏民. 高烈度地震时黄土地层的液化移动[J]. 工程勘察, 1990, 18(6): 1-5. https://www.cnki.com.cn/Article/CJFDTOTAL-GCKC199006000.htm BAI Ming-xue, ZHANG Su-min. Landslide induced by liquefaction of loessial soil during earthquakeofhighintensity[J]. Geotechnical Investigation and Surveying, 1990, 18(6): 1-5. (in Chinese). https://www.cnki.com.cn/Article/CJFDTOTAL-GCKC199006000.htm

[2] NUTTLI O W. The Mississippi Valley earthquakes of 1811 and 1812: Intensities ground motion and magnitudes[J]. Bulletin of the Seismological Society of America, 1973, 63: 227-248. doi: 10.1785/BSSA0630010227

[3] PRAKASH S, PURI V K. Liquefaction of loessial soils[C]//Anon.Proc.of Third International Conference on Seismic Microzonation, Seattle, Wash, 1982: 1101-1107.

[4] WOLF L W, COLLIER J, TUTTLE M, et al. Geophysical reconnaissance of earthquake-induced liquefaction features in the New Madrid seismic zone[J]. Journal of Applied Geophysics, 1998, 39(3): 121-129. doi: 10.1016/S0926-9851(98)00016-0

[5] OWENS P R, RUTLEDGE E M, OSIER S C, et al. The relationship ofsoilscontainingliquefactionfeaturesand redoximorphic features to perched seasonal water tables in the Lower Mississippi River Valley[J]. Quaternary International, 2001, 78(1): 45-51. doi: 10.1016/S1040-6182(00)00114-2

[6] WANG S Y, LUNA R, ONYEJEKWE S. Effect of initial consolidation condition on postcyclic undrained monotonic shear behavior of Mississippi river valley silt[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2016, 142(2): 04015075. doi: 10.1061/(ASCE)GT.1943-5606.0001401

[7] HWANG H, WANG L M, YUAN Z. Comparison of liquefaction potentialofloessinLanzhou, China, and Memphis, USA[J]. SoilDynamicsandEarthquake Engineering, 2000, 20(5/6/7/8): 389-395.

[8] LIU C, SHI B, ZHOU J, etal. Quantificationand characterizationofmicroporositybyimageprocessing, geometric measurement and statistical methods: application on SEM images of clay materials[J]. Applied Clay Science, 2011, 54(1): 97-106. doi: 10.1016/j.clay.2011.07.022

下载:

下载: