Effects of grain size distribution and surface texture on shear behaviors at saturated sand-steel interface

-

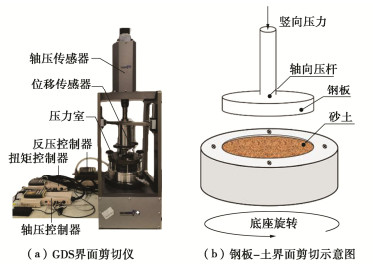

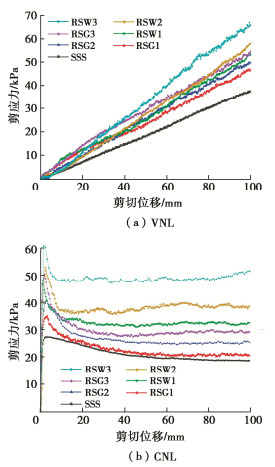

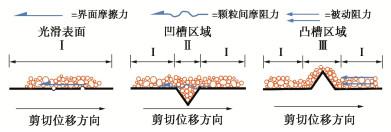

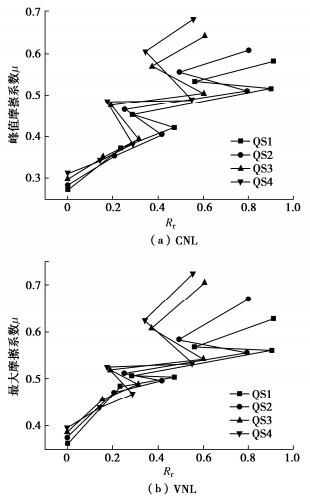

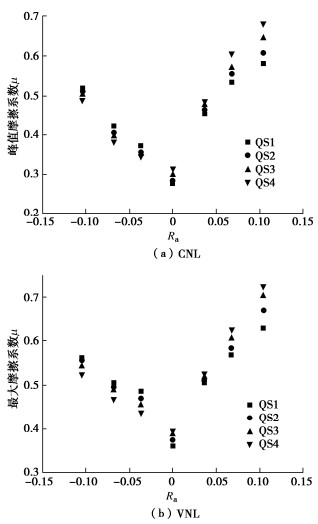

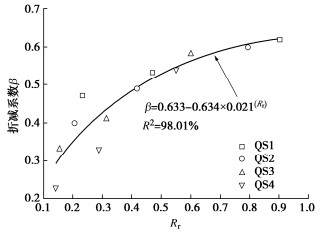

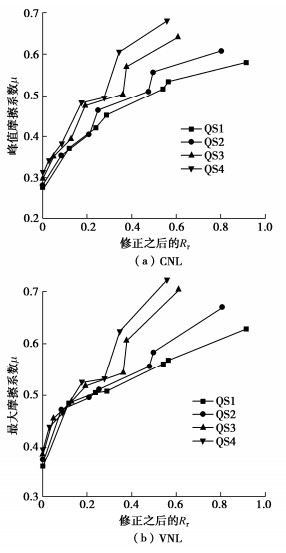

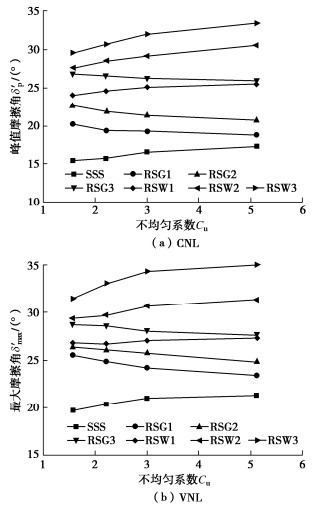

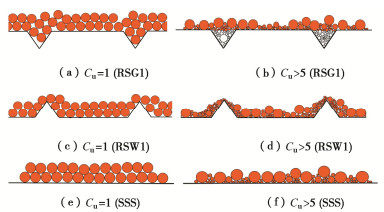

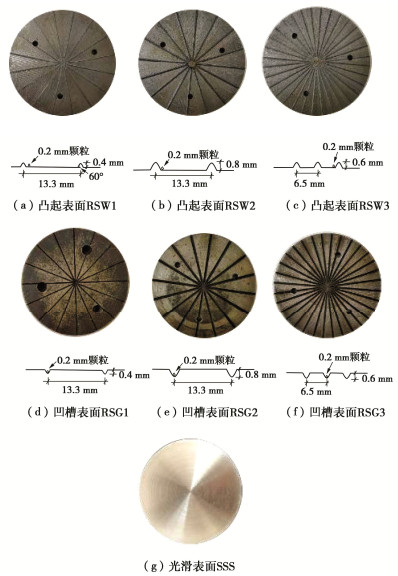

摘要: 钢桩和钢制吸力基础广泛应用于海洋工程,土体与基础结构界面力学特性决定着其承载能力。通过饱和砂-钢界面排水剪切试验,揭示了颗粒级配、表面纹理和法向边界条件对界面剪切特性的影响规律。研究表明:由于颗粒剪切方式和孔隙水压力消散方式的不同,常法向应力(CNL)下剪应力-位移曲线出现明显的应变软化现象。变法向应力(VNL)下,界面剪切强度随法向应力的增大不断提高。对于光滑和凸起构造,界面摩擦角随不均匀系数Cu的增加基本呈线性增长。对于凹槽构造,界面摩擦角随Cu的增加而减小。饱和砂-粗糙度钢板界面剪切效能的发挥受水的影响显著,砂与钢板之间水膜的存在减弱了砂颗粒和钢界面的摩擦,使得界面摩擦性能不能完全发挥。Abstract: The steel piles and steel suction caissons are widely used in ocean engineering, in which the mechanical behaviors of the interface between soils and foundations determine their bearing capacities. A series of saturated sand–steel interface drained shear tests are conducted to reveal the effects of the grain size distribution, surface texture and normal confinement conditions on interfacial shear behaviors. The research shows that due to the differences in the shear mode of sand particles and the dissipation of the pore water pressure, the shear stress-displacement curve under a constant normal load (CNL) experiences an obvious strain-softening phenomenon, whereas the maximum shear stress increases with the increase of the normal stress increment under a variable normal load (VNL). For the smooth and convex surfaces, the interfacial friction angle increases linearly with the increase of Cu. For the groove surfaces, the interfacial friction angle decreases with the increase of Cu. The shear efficiency of the saturated sand-steel plate interface is greatly influenced by water, and the presence of the water film weakens the friction between sand particles and steel plates, thus, the maximum efficiency cannot be developed on interfaces.

-

-

表 1 试样基本物理参数

Table 1 Soil properties

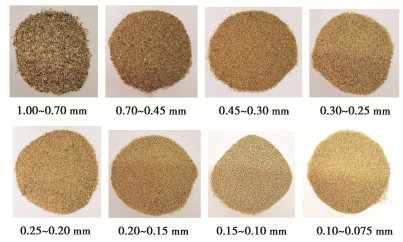

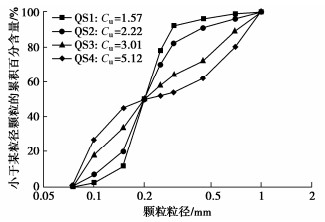

编号 Cu Cc D50/

mmDav/

mm相对密实度Dr/% emax emin 砂样质量/g QS1 1.57 0.99 0.20 0.22 90 1.10 0.61 129.81 QS2 2.22 1.23 0.25 1.01 0.56 128.67 QS3 3.01 0.80 0.33 0.98 0.63 124.28 QS4 5.12 0.33 0.36 1.02 0.65 122.63 表 2 粗糙度评价指标

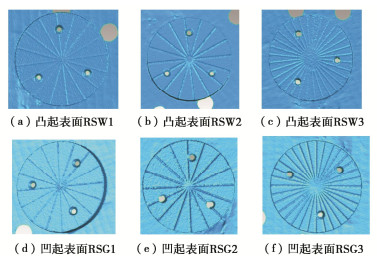

Table 2 Surface roughnesses of different interfaces

表面类型 Rmax/mm Rn Ra/mm D Rr QS1 QS2 QS3 QS4 SSS 0 0 0 0 0 0 0 0 RSW1 0.4 2 0.0365 1.7252 0.286 0.252 0.191 0.175 RSW2 0.8 4 0.0678 1.8269 0.563 0.495 0.375 0.344 RSW3 0.6 3 0.1043 1.9251 0.913 0.803 0.608 0.558 RSG1 0.4 2 0.0365 1.421 0.236 0.207 0.157 0.144 RSG2 0.8 4 0.0678 1.5376 0.474 0.417 0.316 0.290 RSG3 0.6 3 0.1043 1.9047 0.903 0.795 0.602 0.552 表 3 饱和砂土-钢界面剪切方案

Table 3 Shear tests on saturated interfaces

表面类型 试样 CNL/

kPaVNL/

kPa剪切位移

L/mm剪切速率/

(cm·min-1)SSS, RSW1,

RSW2, RSW3,

RSG1, RSG2,

RSG3QS1,

QS2,

QS3,

QS4100 0~100 100 1.0 -

[1] CANAKCI H, HAMED M, CELIK F, et al. Friction characteristics of organic soil with construction materials[J]. Soils and Foundations, 2016, 56(6): 965-972. doi: 10.1016/j.sandf.2016.11.002

[2] FARHADI B, LASHKARI A. Influence of soil inherent anisotropy on behavior of crushed sand-steel interfaces[J]. Soils and Foundations, 2017, 57(1): 111-125. doi: 10.1016/j.sandf.2017.01.008

[3] 李大勇, 侯新宇, 张雨坤, 等. 相对密实度对沉贯中吸力基础桶壁-砂土界面力学特性的影响[J]. 岩土工程学报, 2022, 44(9): 1598-1607. doi: 10.11779/CJGE202209004 LI Dayong, HOU Xinyu, ZHANG Yukun, et al. Effects of relative densities on mechanical characteristics of interface between sand and suction caisson during penetration[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(9): 1598-1607. (in Chinese) doi: 10.11779/CJGE202209004

[4] VAFAEI N, FAKHARIAN K, SADREKARIMI A. Sand-sand and sand-steel interface grain-scale behavior under shearing[J]. Transportation Geotechnics, 2021, 30: 100636. doi: 10.1016/j.trgeo.2021.100636

[5] PORCINO D, FIORAVANTE V, GHIONNA V, et al. Interface behavior of sands from constant normal stiffness direct shear tests[J]. Geotechnical Testing Journal, 2003, 26(3): 289-301.

[6] WANG J F, LIU S, CHENG Y P. Role of normal boundary condition in interface shear test for the determination of skin friction along pile shaft[J]. Canadian Geotechnical Journal, 2017, 54(9): 1245-1256. doi: 10.1139/cgj-2016-0312

[7] NARDELLI A, CACCIARI P P, FUTAI M M. Sand-concrete interface response: the role of surface texture and confinement conditions[J]. Soils and Foundations, 2019, 59(6): 1675-1694. doi: 10.1016/j.sandf.2019.05.013

[8] AFZALI-NEJAD A, LASHKARI A, MARTINEZ A. Stress-displacement response of sand–geosynthetic interfaces under different volume change boundary conditions[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2021, 147(8): 04021062. doi: 10.1061/(ASCE)GT.1943-5606.0002544

[9] HAMMOUD F, BOUMEKIK A. Experimental study of the behaviour of interfacial shearing between cohesive soils and solid materials at large displacement[J]. Asian Journal of Civil Engineering, 2006, 71(1): 63-80.

[10] SAMANTA M, PUNETHA P, SHARMA M. Effect of roughness on interface shear behavior of sand with steel and concrete surface[J]. Geomechanics and Engineering, 2018, 14(4): 387-398.

[11] HAN F, GANJU E S, SALGADO R, et al. Effects of interface roughness, particle geometry, and gradation on the sand–steel interface friction angle[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2018, 144(12): 04018096. doi: 10.1061/(ASCE)GT.1943-5606.0001990

[12] 刘飞禹, 王攀, 王军, 等. 颗粒粒径对格栅-土界面静、动力直剪特性的影响[J]. 岩土力学, 2017, 38(1): 150-156. LIU Feiyu, WANG Pan, WANG Jun, et al. Influence of soil particle size on monotonic and cyclic direct shear behaviors of geogrid-soil interface[J]. Rock and Soil Mechanics, 2017, 38(1): 150-156. (in Chinese)

[13] 王军, 施静, 刘飞禹, 等. 砂土颗粒级配对格栅-土界面静、动力直剪特性的影响[J]. 岩土力学, 2019, 40(1): 109-117. WANG Jun, SHI Jing, LIU Feiyu, et al. Effect of particle gradation on static and dynamic direct shear properties of geogrid-sand interface[J]. Rock and Soil Mechanics, 2019, 40(1): 109-117. (in Chinese)

[14] WANG H L, ZHOU W H, YIN Z Y, et al. Effect of grain size distribution of sandy soil on shearing behaviors at soil–structure interface[J]. Journal of Materials in Civil Engineering, 2019, 31(10): 04019238. doi: 10.1061/(ASCE)MT.1943-5533.0002880

[15] KOU H L, DIAO W Z, ZHANG W C, et al. Experimental study of interface shearing between calcareous sand and steel plate considering surface roughness and particle size[J]. Applied Ocean Research, 2021, 107: 102490. doi: 10.1016/j.apor.2020.102490

[16] 刘亚琼. 粗颗粒含量对粗粒土—混凝土结构接触面剪切力学性质的影响[J]. 工程勘察, 2022, 50(2): 7-12. LIU Yaqiong. Influence of coarse particle content on shear mechanical properties of interface between coarse grained soil and concrete structure[J]. Geotechnical Investigation & Surveying, 2022, 50(2): 7-12. (in Chinese)

[17] SU L J, ZHOU W H, CHEN W B, et al. Effects of relative roughness and mean particle size on the shear strength of sand-steel interface[J]. Measurement, 2018, 122: 339-346. doi: 10.1016/j.measurement.2018.03.003

[18] TEHRANI F S, HAN F, SALGADO R, et al. Effect of surface roughness on the shaft resistance of non-displacement piles embedded in sand[J]. Géotechnique, 2016, 66(5): 386-400. doi: 10.1680/jgeot.15.P.007

[19] 金子豪, 杨奇, 陈琛, 等. 粗糙度对混凝土-砂土接触面力学特性的影响试验研究[J]. 岩石力学与工程学报, 2018, 37(3): 754-765. JIN Zihao, YANG Qi, CHEN Chen, et al. Experimental study on effects of the roughness on mechanical behaviors of concrete-sand interface[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(3): 754-765. (in Chinese)

[20] YOSHIMI Y, KISHIDA T. A ring torsion apparatus for evaluating friction between soil and metal surfaces[J]. Geotechnical Testing Journal, 1981, 4(4): 145. doi: 10.1520/GTJ10783J

[21] UESUGI M, KISHIDA H. Frictional resistance at yield between dry sand and mild steel[J]. Soils and Foundations, 1986, 26(4): 139-149. doi: 10.3208/sandf1972.26.4_139

[22] UESUGI M, KISHIDA H. Influential factors of friction between steel and dry sands[J]. Soils and Foundations, 1986, 26(2): 33-46. doi: 10.3208/sandf1972.26.2_33

[23] MARTINEZ A, FROST J D. The influence of surface roughness form on the strength of sand–structure interfaces[J]. Géotechnique Letters, 2017, 7(1): 104-111. doi: 10.1680/jgele.16.00169

[24] SUBBA R K S, ALLAM M M, ROBINSON R G, et al. Interfacial friction between sands and solid surfaces[J]. Geotechnical Engineering, 1998, 131(2): 75-82.

[25] 李广信. 高等土力学[M]. 北京: 清华大学出版社, 2004. LI Guangxin. Advanced Soil Mechanics[M]. Beijing: Tsinghua University Press, 2004. (in Chinese)

[26] NAMJOO A M, JAFARI K, TOUFIGH V. Effect of particle size of sand and surface properties of reinforcement on sand-geosynthetics and sand-carbon fiber polymer interface shear behavior[J]. Transportation Geotechnics, 2020, 24: 100403. doi: 10.1016/j.trgeo.2020.100403

[27] CABALAR A F, DULUNDU K, TUNCAY K. Strength of various sands in triaxial and cyclic direct shear tests[J]. Engineering Geology, 2013, 156: 92-102. doi: 10.1016/j.enggeo.2013.01.011

[28] KOERNER R M. Designing with Geosynthetics[M]. Engelwood Cliffs: Prentice Hall Inc, 1990.

-

其他相关附件

下载:

下载: