Stress and deformation properties of shield segmental linings under internal water pressures

-

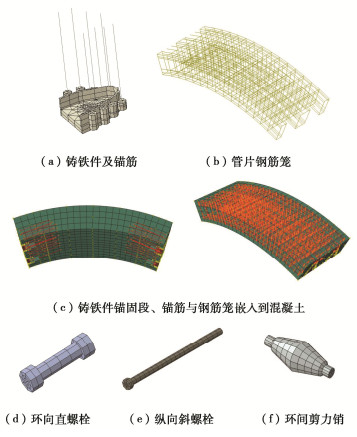

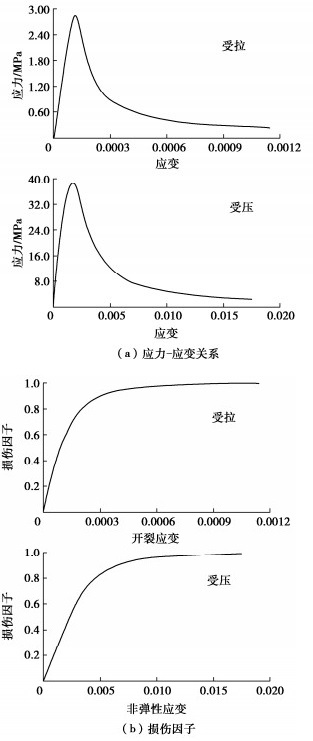

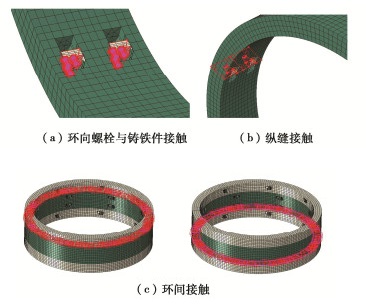

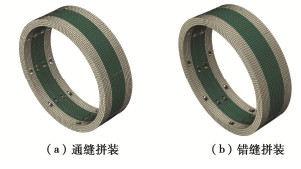

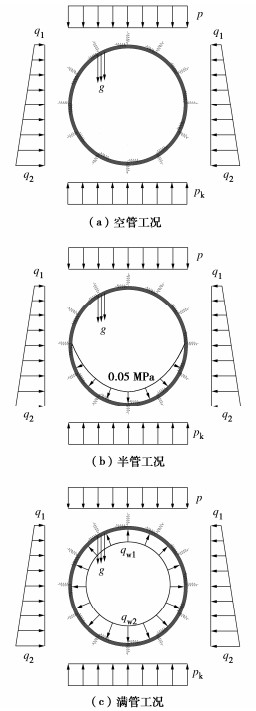

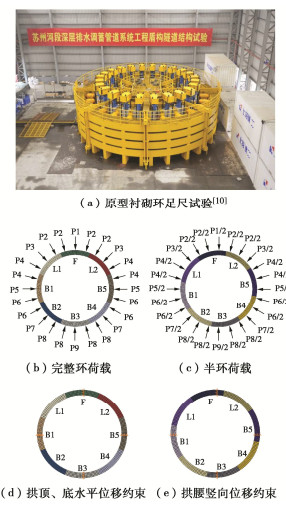

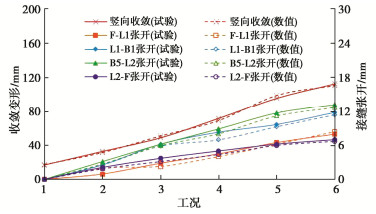

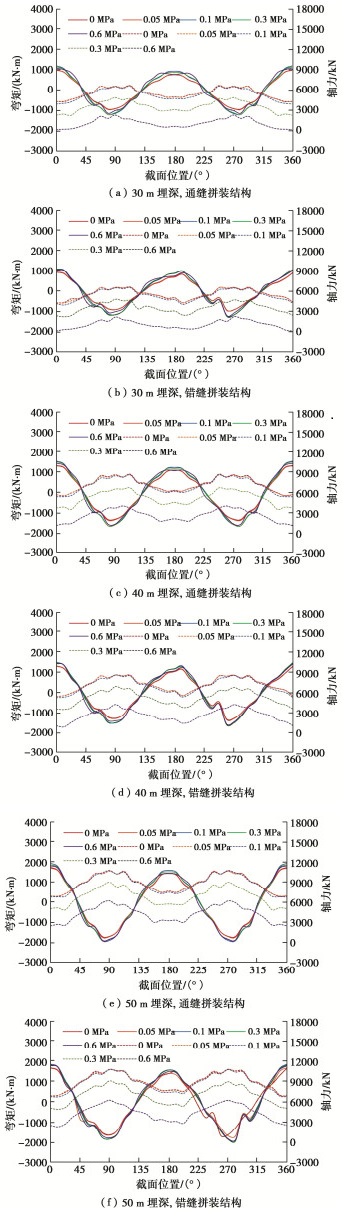

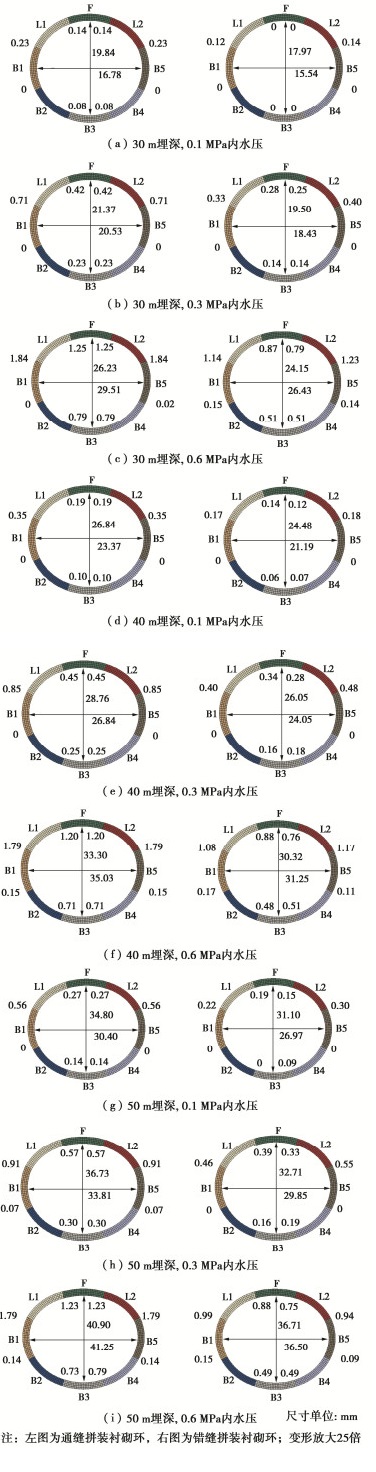

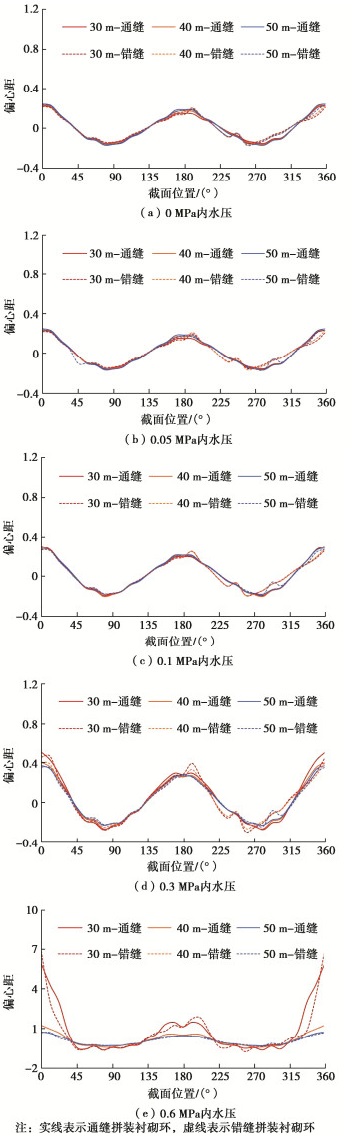

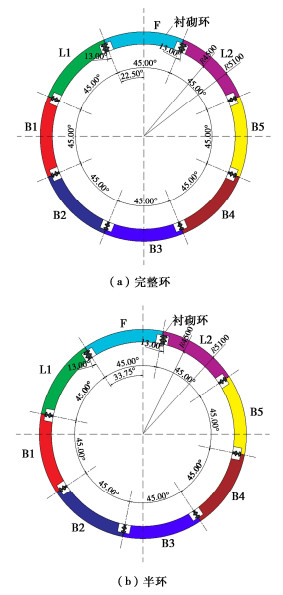

摘要: 对不同埋深的通缝和错缝拼装盾构衬砌结构在内水压作用下的力学响应开展研究,分析了内水压、隧道埋深和衬砌拼装方式对盾构衬砌承载特性的影响规律。研究结果表明,隧道内水从空管变化至满管过程中,衬砌环变形持续增大,内力变化呈现三阶段特性。第一阶段为空管至半管阶段,衬砌环弯矩增大、轴力减小,但二者的变化幅度极小。第二阶段为半管至刚刚满管阶段,衬砌环弯矩增大、轴力减小,轴力的变化幅度小于弯矩。第三阶段为满管后内压增加阶段,衬砌环弯矩和轴力同时减小,但轴力的减幅远大于弯矩。对于有内压作用的盾构衬砌,埋深减小时衬砌结构的内力与变形会随之减小,但局部接缝张开及螺栓应力可能出现增大的现象,较浅覆土处衬砌环接缝的安全储备应引起足够重视。当隧道埋深及内部水压荷载相同时,错缝拼装衬砌结构的收敛变形、局部接缝变形和接缝部位螺栓的受力均优于通缝拼装结构,承受内水压的盾构衬砌可优先考虑采用错缝的方式拼装。Abstract: The mechanical responses of continuous- and stagger-jointed shield lining structures with different buried depths and internal water pressures are investigated, and then the influences of the internal pressure, buried depth and lining assembly manner on the stress and deformation properties of shield segmental linings are analyzed. The results show that the deformations of the shield lining rings increase, and the change of the internal forces presents the characteristic of three stages in the process of inner water inside the tunnel from the empty pipe state to the full one. The first stage is from the empty pipe state to the half one, in which the bending moments and axial forces of the lining rings increase and decrease, respectively, but the change ranges of the bending moments and axial forces are very small. The second stage is from the half pipe state to the full one, in which the bending moments and axial forces of the lining rings increase and decrease, respectively, and the change range of the axial forces is less than that of the bending moments. The third stage is the increase of the internal pressures after the pipe is full, in which the bending moments and axial forces of the lining rings decrease at the same time, but the reduction of the axial forces is much greater than that of the bending moments. The internal forces and deformations of the lining structures reduce with the decrease of the buried depth, but the local joint opening and bolt stress may increase in the shield segmental linings under the internal water pressure. Thus, enough attention should be paid to the safety reserve of the joints in the linings with shallow buried depth. In addition, under the same buried depth at tunnel top and internal water pressure inside the tunnel, the convergence deformation, local joint opening and stress of the bolts at the joint positions of the staggered-jointed lining structures are better than those of the continuous-jointed ones, which means the staggered-jointed assembly manner should be preferred for the shield linings under the internal water pressures.

-

-

表 1 衬砌环外侧土压力

Table 1 Earth pressures outside lining rings

埋深/m p/kPa pk/kPa q1/kPa q2/kPa 30 540 585 420 560 40 720 765 560 700 50 900 945 700 840 表 2 衬砌环纵缝螺栓最大应力

Table 2 Maximum stresses of bolts at segmental joints of lining rings

内水压/

MPa30 m埋深 40 m埋深 50 m埋深 通缝结构螺栓应力/MPa 错缝结构螺栓应力/MPa 通缝结构螺栓应力/MPa 错缝结构螺栓应力/MPa 通缝结构螺栓应力/MPa 错缝结构螺栓应力/MPa 0.1 70.9 61.8 90.0 71.4 112.8 84.7 0.3 176.2 142.9 189.7 147.7 200.8 156.5 0.6 542.7 371.5 481.3 317.5 428.0 303.8 -

[1] 周龙, 朱合华, 闫治国, 等. 深埋高内水压盾构隧道管片衬砌力学特性足尺试验研究[J]. 土木工程学报, 2022, 55(9): 94-105, 117. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC202209009.htm ZHOU Long, ZHU Hehua, YAN Zhiguo, et al. Full-scale loading test on mechanical properties of deep-buried shield segmental linings bearing high inner water pressure[J]. China Civil Engineering Journal, 2022, 55(9): 94-105, 117. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC202209009.htm

[2] 王建平, 何贞俊, 潘文慰, 等. 广州深隧排水系统东濠涌试验段物理模型试验研究[J]. 中国给水排水, 2020, 36(23): 108-112. https://www.cnki.com.cn/Article/CJFDTOTAL-GSPS202023022.htm WANG Jianping, HE Zhenjun, PAN Wenwei, et al. Physical model test of Donghaochong test section of deep tunnel drainage system in Guangzhou city[J]. China Water & Wastewater, 2020, 36(23): 108-112. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GSPS202023022.htm

[3] 安瑞冬, 游景皓, 廖磊, 等. 深层隧道排水系统中井隧水力学特性研究[J]. 水利学报, 2021, 52(12): 1498-1507. https://www.cnki.com.cn/Article/CJFDTOTAL-SLXB202112010.htm AN Ruidong, YOU Jinghao, LIAO Lei, et al. Study on the hydraulic characteristics of dropshaft and tunnel in the deep tunnel drainage system[J]. Journal of Hydraulic Engineering, 2021, 52(12): 1498-1507. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SLXB202112010.htm

[4] 朱建文, 孟晗, 闫治国, 等. 高承载力盾构管片接头预埋件抗拉性能试验[J]. 中国公路学报, 2017, 30(8): 149-155. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGL201708017.htm ZHU Jiannwen, MENG Han, YAN Zhiguo. Test of tensile performance for embeded part with high bearing capability of segment joints in shield tunnel[J]. China Journal of Highway and Transport, 2017, 30(8): 149-155. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGL201708017.htm

[5] GUO R, ZHANG M Y, XIE H M, et al. Model test study of the mechanical characteristics of the lining structure for an urban deep drainage shield tunnel[J]. Tunnelling and Underground Space Technology, 2019, 91: 103014. doi: 10.1016/j.tust.2019.103014

[6] 刘威, 王祺, 庄欠伟, 等. 深埋排水调蓄盾构隧道管片1∶1力学试验系统的研发与应用[J]. 中国公路学报, 2020, 33(2): 103-113, 157. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGL202002010.htm LIU Wei, WANG Qi, ZHUANG Qian-wei, et al. Development and application of a 1∶1 mechanical testing system for deeply-buried water storage and sewage shield tunnel[J]. China Journal of Highway and Transport, 2020, 33(2): 103-113, 157. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGL202002010.htm

[7] HUANG X, LIU W, ZHANG Z X, et al. Exploring the three-dimensional response of a water storage and sewage tunnel based on full-scale loading tests[J]. Tunnelling and Underground Space Technology, 2019, 88: 156-168.

[8] HUANG X, LIU W, ZHANG Z X, et al. Structural behavior of segmental tunnel linings for a large stormwater storage tunnel: insight from full-scale loading tests[J]. Tunnelling and Underground Space Technology, 2020, 99: 103376.

[9] ZHANG Z X, LIU W, HUANG X, et al. Exploring the three-dimensional response of water storage and sewage tunnel based on 3D finite element modeling[J]. Tunnelling and Underground Space Technology, 2022, 120: 104269.

[10] ZHOU L, ZHU H H, SHEN Y, et al. Full-scale experimental investigation on progressive failure characteristics of shield segmental lining connected through segmental joints containing ductile-iron joint panels[J]. Archives of Civil and Mechanical Engineering, 2022, 22: 120.

[11] ZHOU L, SHEN Y, GUAN L X, et al. Full-scale experiment for segmental linings of deep-buried shield tunnels bearing high inner water pressure: comparison of mechanical behaviors of continuous- and stagger-jointed structures[J]. Underground Space, 2023, 8: 252-266.

[12] 丁发兴, 余志武. 混凝土受拉力学性能统一计算方法[J]. 华中科技大学学报(城市科学版), 2004, 21(3): 29-34. https://www.cnki.com.cn/Article/CJFDTOTAL-WHCJ200403008.htm DING Faxing, YU Zhiwu. Unified calculation method of mechanical properties of concrete in tension[J]. Journal of Huazhong University of Science and Technology (Urban Science), 2004, 21(3): 29-34. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-WHCJ200403008.htm

[13] 余志武, 丁发兴. 混凝土受压力学性能统一计算方法[J]. 建筑结构学报, 2003, 24(4): 41-46. https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB200304005.htm YU Zhiwu, DING Faxing. Unified calculation method of compressive mechanical properties of concrete[J]. Journal of Building Structures, 2003, 24(4): 41-46. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JZJB200304005.htm

[14] SU D, CHEN W J, WANG X T, et al. Numerical study on transverse deformation characteristics of shield tunnel subject to local soil loosening[J]. Underground Space, 2022, 7(1): 106-121.

[15] KOYAMA Y. Present status and technology of shield tunneling method in Japan[J]. Tunneling and Underground Space Technology, 2003, 18(2/3): 145-159.

[16] 廖少明, 门燕青, 肖明清, 等. 软土盾构法隧道纵向应力松弛规律的实测分析[J]. 岩土工程学报, 2017, 39(5): 795-803. doi: 10.11779/CJGE201705003 LIAO Shaoming, MEN Yanqing, XIAO Mingqing, et al. Field tests on longitudinal stress relaxation along shield tunnel in soft ground[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(5): 795-803. (in Chinese) doi: 10.11779/CJGE201705003

[17] 柳献, 杨振华, 门燕青. 盾构隧道环间纵向压力时变规律研究[J]. 岩土工程学报, 2021, 43(1): 188-193. doi: 10.11779/CJGE202101022 LIU Xian, YANG Zhenhua, MEN Yanqing. Temporal variation laws of longitudinal stress on cross section of shield tunnels[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(1): 188-193. (in Chinese) doi: 10.11779/CJGE202101022

[18] CHEN R P, CHEN S, WU H N, et al. Investigation on deformation behavior and failure mechanism of a segmental ring in shield tunnels based on elaborate numerical simulation[J]. Engineering Failure Analysis, 2020, 117: 104960.

[19] 黄宏伟, 徐凌, 严佳梁, 等. 盾构隧道横向刚度有效率研究[J]. 岩土工程学报, 2006, 28(1): 11-18. http://www.cgejournal.com/cn/article/id/11891 HUANG Hongwei, XU Ling, YAN Jialiang, et al. Study on transverse effective rigidity ratio of shield tunnels[J]. Chinese Journal of Geotechnical Engineering, 2006, 28(1): 11-18. (in Chinese) http://www.cgejournal.com/cn/article/id/11891

[20] 王士民, 申兴柱, 何祥凡, 等. 不同拼装方式下盾构隧道管片衬砌受力与破坏模式模型试验研究[J]. 土木工程学报, 2017, 50(6): 114-124. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201706013.htm WANG Shimin, SHEN Xingzhu, HE Xiangfan, et al. A model test for the mechanical property and failure mode of lining segments with different assembly types of shield tunnel[J]. China Civil Engineering Journal, 2017, 50(6): 114-124. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201706013.htm

-

其他相关附件

下载:

下载: