Experimental evaluation of performance of compaction-grouted soil nails using geotextile

-

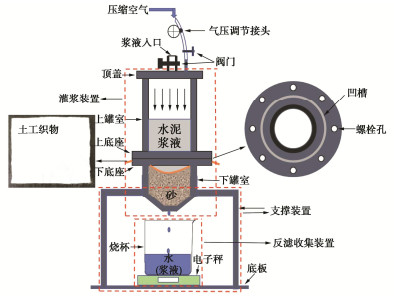

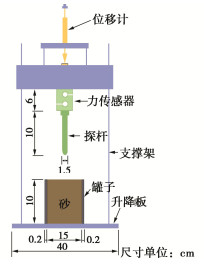

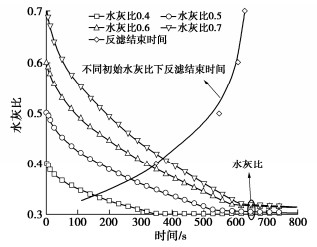

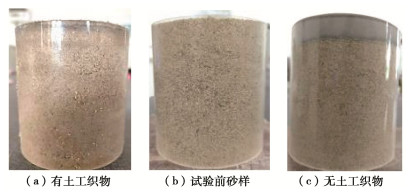

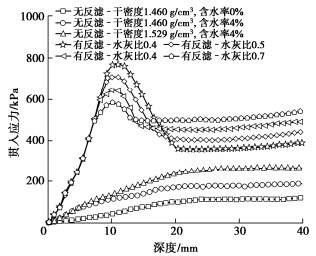

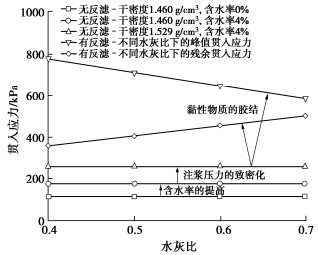

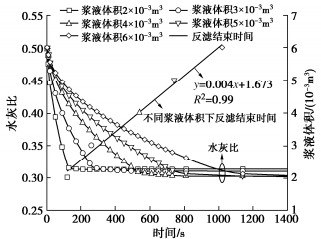

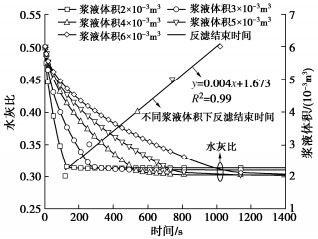

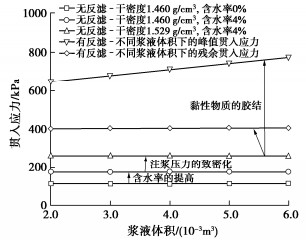

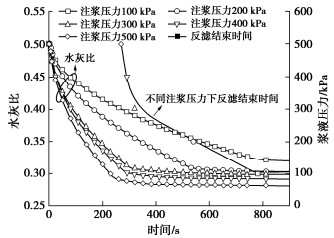

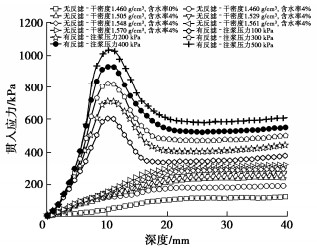

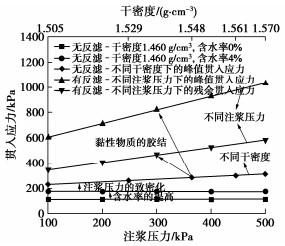

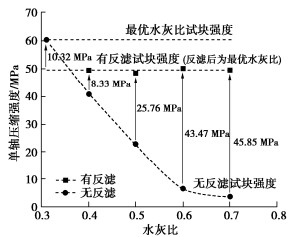

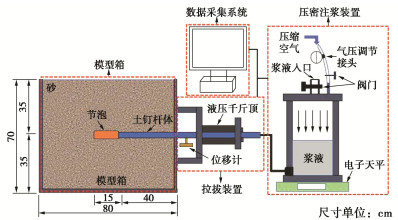

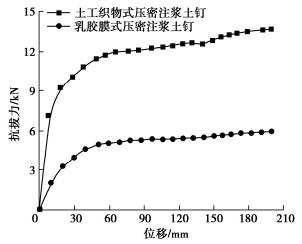

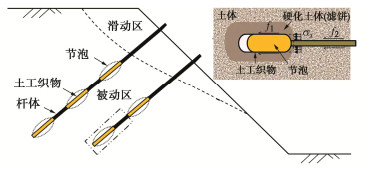

摘要: 针对乳胶膜式压密注浆土钉的潜在缺陷,提出了采用土工织物替代乳胶膜改进该土钉的新思路。首先,基于自研的土工织物反滤性能测定装置,开展了一系列水泥浆液反滤试验,研究了水灰比、浆液体积和注浆压力对土工织物反滤性能的影响,得到了注浆过程中上述影响因素影响下反滤时间和水灰比的变化规律。其次,对反滤前/后的砂土进行了贯入试验,评估了由于浆液中黏性物质入渗引起的周围土体强度提高。再次,对反滤前/后的水泥试块进行了单轴压缩试验,探明了节泡(水泥试块)强度显著提高的原因是土工织物反滤过程中节泡内水灰比的降低。最后,开展了土工织物和乳胶膜式压密注浆土钉的两组对比拉拔试验,验证了土工织物改进压密注浆土钉的优越性。研究成果能为压密注浆土钉的优化和应用奠定基础。Abstract: A new idea that adopts a geotextile instead of a latex membrane to improve the performance of a pressure-grouted soil nail is proposed. First, based on the self-developed device for testing filtration performance of the geotextile, a series of cement slurry filtration tests are carried out to study the influences of the water-cement ratio, slurry volume and grouting pressure on its filtration performance. The variations in the filtration time and water-cement ratio under the changes in the aforementioned influencing factors during pressure grouting are obtained. Second, a series of penetration tests on the surrounding sands before and after filtration tests are conducted, and the strength improvement due to the infiltration of cohesive substances from grout slurry is subsequently evaluated. Third, the uniaxial compression tests are carried out on the cement blocks before and after the filtration tests, and it is found that the strength of the grout bulb (cement block) largely increases because the water-cement ratio in the grout bulb is significantly reduced during the filtration of the geotextile. Finally, two series of pull-out tests on the compaction-grouted soil nails with a geotextile and a latex membrane are carried out to verify the superiority of improving the compaction-grouted soil nails by the geotextile. This study is helpful for the optimization and application of the compaction-grouted soil nails by using the geotextile.

-

Keywords:

- compaction-grouted soil nail /

- geotextile /

- water-cement ratio /

- slurry volume /

- grouting pressure

-

-

表 1 水泥的相关参数

Table 1 Related parameters of cement

相关参数 细度(45 um)/% 比表面积/(m2·kg-1) 烧失量/% 初凝/min 终凝/min 数值 10.8 33.5 3.54 178 228 表 2 土工织物的相关参数

Table 2 Related parameters of geotextile

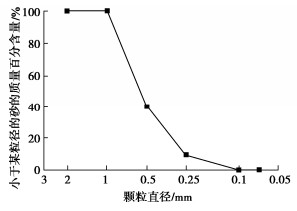

相关参数 克重/(g·m-2) 厚度/mm 断裂强力/(kN·m-1) 等效孔径/mm 幅宽偏差/% 数值 300 2.2 15 0.07~0.2 -0.5 表 3 砂的物理性质参数

Table 3 Related parameters of sand

相关参数 相对质量密度 最大干密度/(g·cm-3) 最小干密度/(g·cm-3) 数值 2.67 1.70 1.42 表 4 反滤试验方案

Table 4 Test schemes for filtration

影响因素 水灰比 浆液体积/(10-3·m3) 注浆压力/kPa 初始干密度/(g·cm-3) 初始含水率/% 水灰比 0.4 4 200 1.460 0 0.5 0.6 0.7 浆液体积/(10-3·m3) 0.5 2 200 1.460 0 3 4 5 6 注浆压力/kPa 0.5 4 100 1.460 0 200 300 400 500 表 5 小型贯入试验方案

Table 5 Test schemes for small-scale penetration

影响因素 水灰比 浆液体积/(10-3·m3) 注浆压力/kPa 初始干密度/(g·cm-3) 初始含水率/% 砂样经过反滤(土工织物) 0.4 4 200 1.460 0 0.5 0.6 0.7 0.5 2 200 1.460 0 3 4 5 6 0.5 4 100 1.460 0 200 300 400 500 砂样未经反滤(乳胶膜) — — — 1.460 0 1.460 4 1.505 1.529 1.548 1.561 1.570 -

[1] 叶新宇, 彭锐, 马新岩, 等. 压密效应对新型压密注浆土钉的强化研究[J]. 岩土工程学报, 2021, 43(9): 1649–1656, 1738. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202109014.htm YE Xin-yu, PENG Rui, MA Xin-yan, et al. Enhancement of compaction grouting on a compaction-grouted soil nail in sand[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(9): 1649–1656, 1738. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202109014.htm

[2] YE X Y, WANG S Y, LI Q, et al. Negative effect of installation on performance of a compaction-grouted soil nail in poorly graded stockton beach sand[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2020, 146(8): 04020061. doi: 10.1061/(ASCE)GT.1943-5606.0002301

[3] YE X Y, WANG S Y, WANG Q, et al. Numerical and experimental studies of the mechanical behaviour for compaction grouted soil nails in sandy soil[J]. Computers and Geotechnics, 2017, 90: 202–214. doi: 10.1016/j.compgeo.2017.06.011

[4] YE X Y, WANG S Y, XIAO X, et al. Numerical study for compaction-grouted soil nails with multiple grout bulbs[J]. International Journal of Geomechanics, 2019, 19(2): 04018193. doi: 10.1061/(ASCE)GM.1943-5622.0001342

[5] 唐琳, 唐晓武, 孙凯. 不等轴双向拉伸无纺织物孔径变化理论研究[J]. 岩土力学, 2017, 38(12): 3597–3603. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201712027.htm TANG Lin, TANG Xiao-wu, SUN Kai. Analytical solutions for pore size of nonwoven geotextiles under unequal biaxial tensile strain[J]. Rock and Soil Mechanics, 2017, 38(12): 3597–3603. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201712027.htm

[6] PALMEIRA E M, TATTO J. Behaviour of geotextile filters in armoured slopes subjected to the action of waves[J]. Geotextiles and Geomembranes, 2015, 43(1): 46–55. doi: 10.1016/j.geotexmem.2014.11.003

[7] ALVAREZ I E, RUBIO R, RICALDE H. Beach restoration with geotextile tubes as submerged breakwaters in Yucatan, Mexico[J]. Geotextiles and Geomembranes, 2007, 25(4/5): 233–241. http://www.onacademic.com/detail/journal_1000034019072210_aeef.html

[8] LAWSON C R. Geotextile containment for hydraulic and environmental engineering[J]. Geosynthetics International, 2008, 15(6): 384–427. doi: 10.1680/gein.2008.15.6.384

[9] TALAMKHANI S, NAEINI S A. The undrained shear behavior of reinforced clayey sand[J]. Geotechnical and Geological Engineering, 2021, 39(1): 265–283. doi: 10.1007/s10706-020-01490-4

[10] YEE T W, LAWSON C R, WANG Z Y, et al. Geotextile tube dewatering of contaminated sediments, Tianjin Eco-City, China[J]. Geotextiles and Geomembranes, 2012, 31: 39–50. doi: 10.1016/j.geotexmem.2011.07.005

[11] 杨春和, 张超, 李全明, 等. 大型高尾矿坝灾变机制与防控方法[J]. 岩土力学, 2021, 42(1): 1–17. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202101002.htm YANG Chun-he, ZHANG Chao, LI Quan-ming, et al. Disaster mechanism and prevention methods of large-scale high tailings dam[J]. Rock and Soil Mechanics, 2021, 42(1): 1–17. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX202101002.htm

[12] 乐超, 徐超, 吴雪峰, 等. 两种塑料排水板滤膜淤堵特性试验研究[J]. 岩土力学, 2014, 35(9): 2529–2534. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201409014.htm LE Chao, XU Chao, WU Xue-feng, et al. Experimental research on clogging characteristic of two types of PVD filters[J]. Rock and Soil Mechanics, 2014, 35(9): 2529–2534. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201409014.htm

[13] 唐琳, 唐晓武, 王艳, 等. 不等轴双向拉应变下有纺织物孔径变化试验研究[J]. 岩土工程学报, 2016, 38(8): 1535–1540. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201608023.htm TANG Lin, TANG Xiao-wu, WANG Yan, et al. Experimental study on pore size characteristics of woven geotextiles subjected to unequal biaxial tensile strains[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(8): 1535–1540. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201608023.htm

[14] 佘巍, 陈轮, 王钊. 无纺土工织物保土应用中的概率设计准则[J]. 岩土力学, 2007, 28(10): 2052–2054, 2059. doi: 10.3969/j.issn.1000-7598.2007.10.008 SHE Wei, CHEN Lun, WANG Zhao. A probabilistic criterion for nonwoven geotextiles retention application[J]. Rock and Soil Mechanics, 2007, 28(10): 2052–2054, 2059. (in Chinese) doi: 10.3969/j.issn.1000-7598.2007.10.008

[15] 吴纲, 雷国辉, 姜红. 有纺土工织物覆土条件下的渗透特性试验研究[J]. 岩土工程学报, 2017, 39(增刊1): 161–165. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2017S1033.htm WU Gang, LEI Guo-hui, JIANG Hong. Experimental study on permeability of woven geotextile covered with soil[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(S1): 161–165. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2017S1033.htm

[16] 汪帅, 庄艳峰, 邓洪, 等. 双向拉伸与水流条件对反滤系统性能的影响[J]. 武汉大学学报(工学版), 2016, 49(2): 264–268. https://www.cnki.com.cn/Article/CJFDTOTAL-WSDD201602018.htm WANG Shuai, ZHUANG Yan-feng, DENG Hong, et al. Influences of bidirectional tensile strain and flow conditions on geotextile filtration[J]. Engineering Journal of Wuhan University, 2016, 49(2): 264–268. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-WSDD201602018.htm

[17] 叶新宇, 彭锐, 张升, 等. 一种用于压密注浆土钉的土工织物性能测试系统及方法: CN110595985A[P]. 2019-12-20. YE Xin-yu, PENG Rui, ZHANG Sheng, et al. System and Method for Testing Performance of Geotextile for Compaction Grouting Soil Nails: CN110595985A[P]. 2019-12-20. (in Chinese)

[18] 彭锐, 马新岩, 叶新宇, 等. 一种用于压密注浆土钉的土工织物性能测试系统: CN210953739U[P]. 2020-07-07. PENG Rui, MA Xin-yan, YE Xin-yu, et al. Geotextile Performance Testing System for Compaction Grouting Soil Nails: CN210953739U[P]. 2020-07-07. (in Chinese)

[19] YE X Y, WANG S Y, WANG Q, et al. The influence of the degree of saturation on compaction-grouted soil nails in sand[J]. Acta Geotechnica, 2019, 14(4): 1101–1111. doi: 10.1007/s11440-018-0706-x

[20] 白彬, 唐晓武, 唐琳, 等. 等双轴拉应变对无纺土工织物孔径变化的影响[J]. 岩土力学, 2015, 36(6): 1615–1621, 1626. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201506012.htm BAI Bin, TANG Xiao-wu, TANG Lin, et al. Influence of equal biaxial tension on opening sizes of nonwoven geotextiles[J]. Rock and Soil Mechanics, 2015, 36(6): 1615–1621, 1626. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201506012.htm

[21] 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 2003. Standard for Test Method of Mechanical Properties on Ordinary Concrete: GB/T 50081—2002[S]. 2003. (in Chinese)

[22] LI X X, WU Z M, ZHENG J J, et al. Effect of loading rate on the bond behaviour of deformed steel bars in concrete subjected to lateral pressure[J]. Materials and Structures, 2016, 49(6): 2097–2111. doi: 10.1617/s11527-015-0636-0

[23] CAO L, GUO J T, TIAN J H, et al. Preparation of Ca/Al-Layered Double Hydroxide and the influence of their structure on early strength of cement[J]. Construction and Building Materials, 2018, 184: 203–214. doi: 10.1016/j.conbuildmat.2018.06.186

下载:

下载: