Experiments and numerical simulations on pressure-arch effect for a tunnel in loose deposits

-

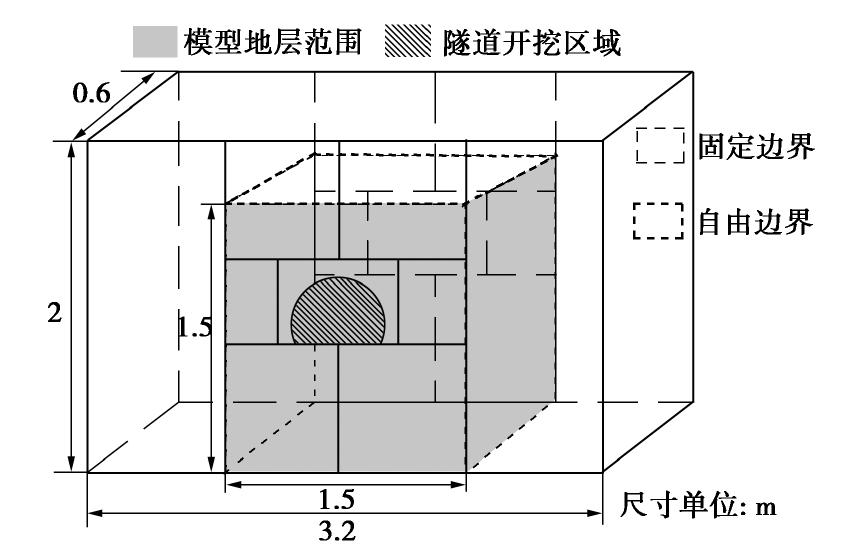

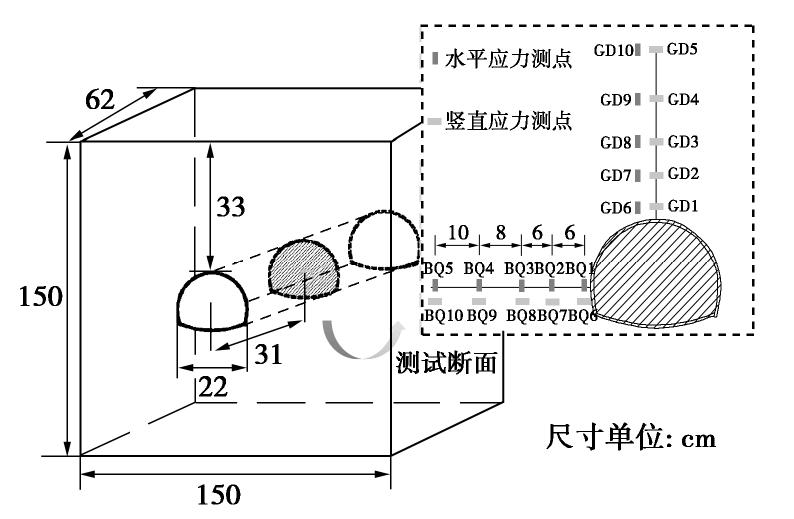

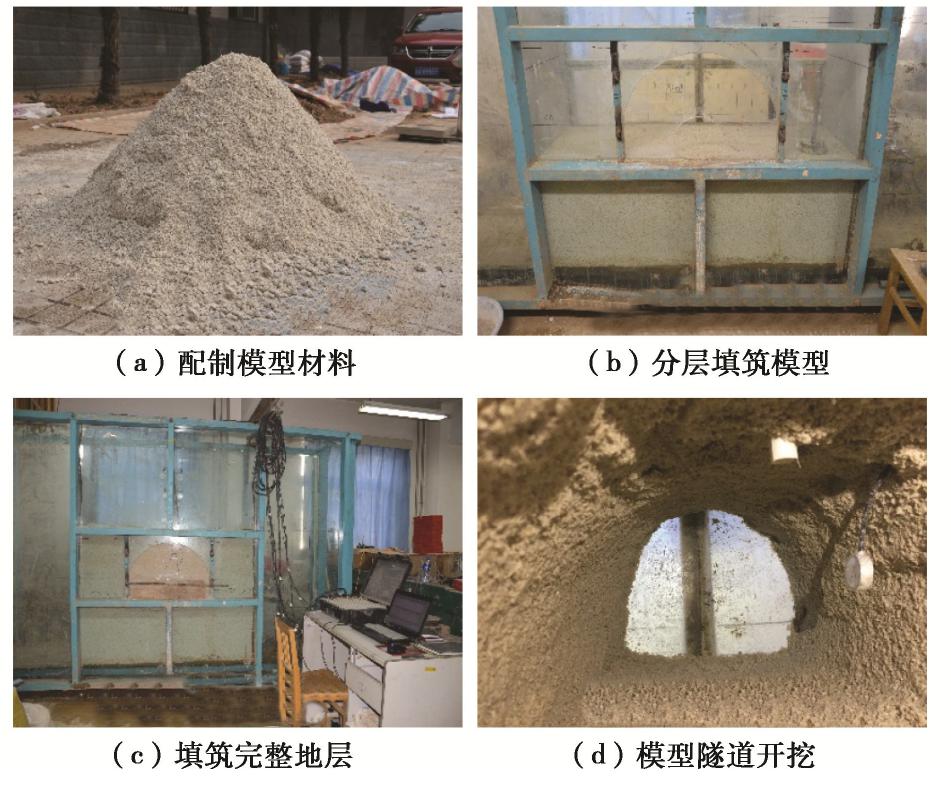

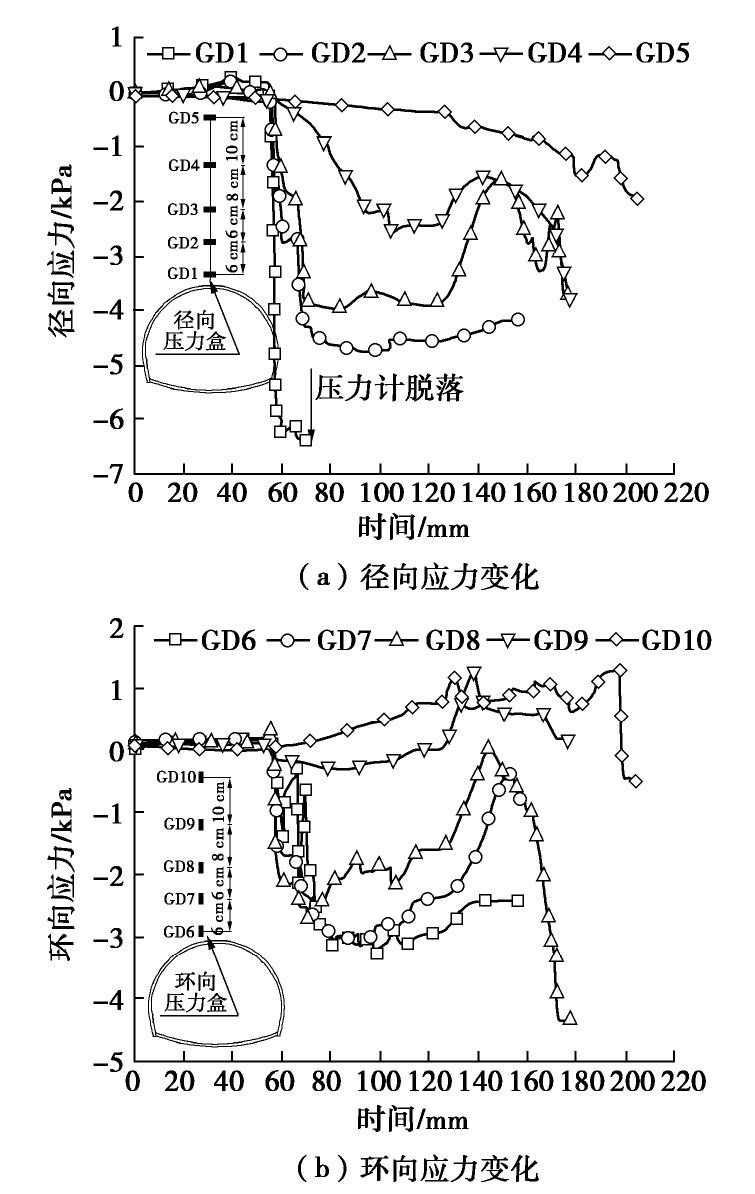

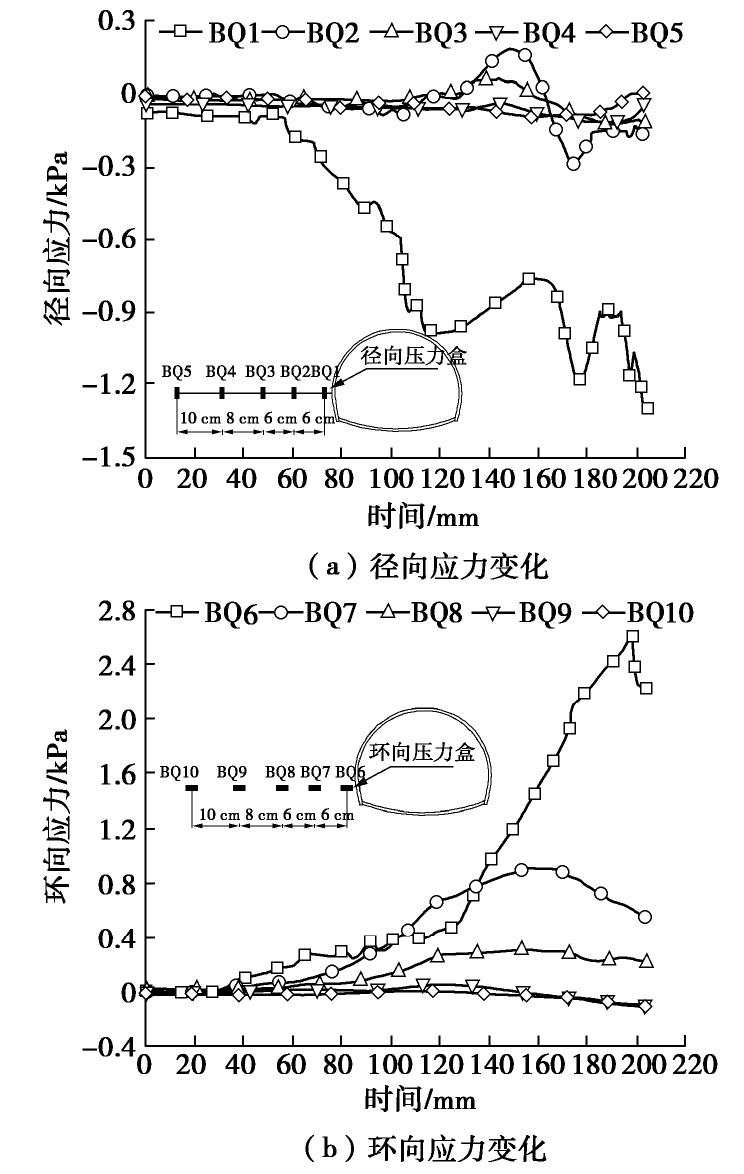

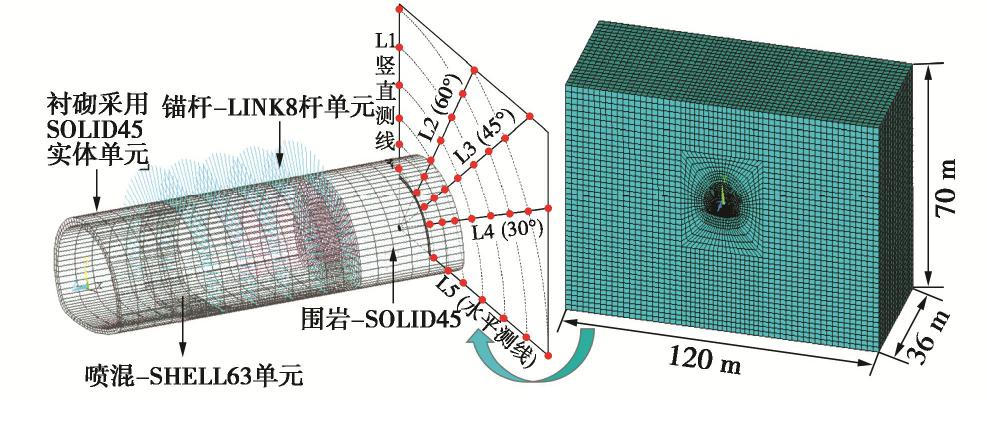

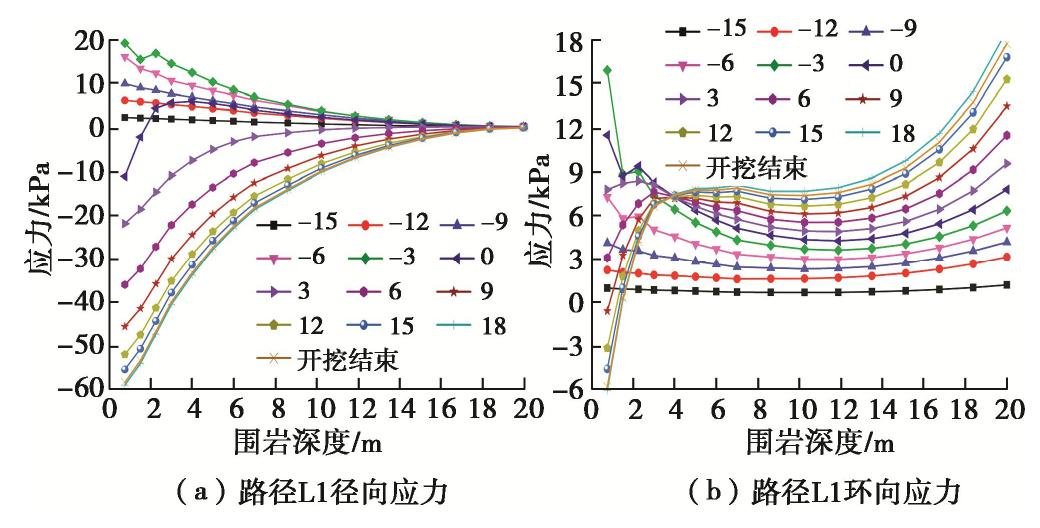

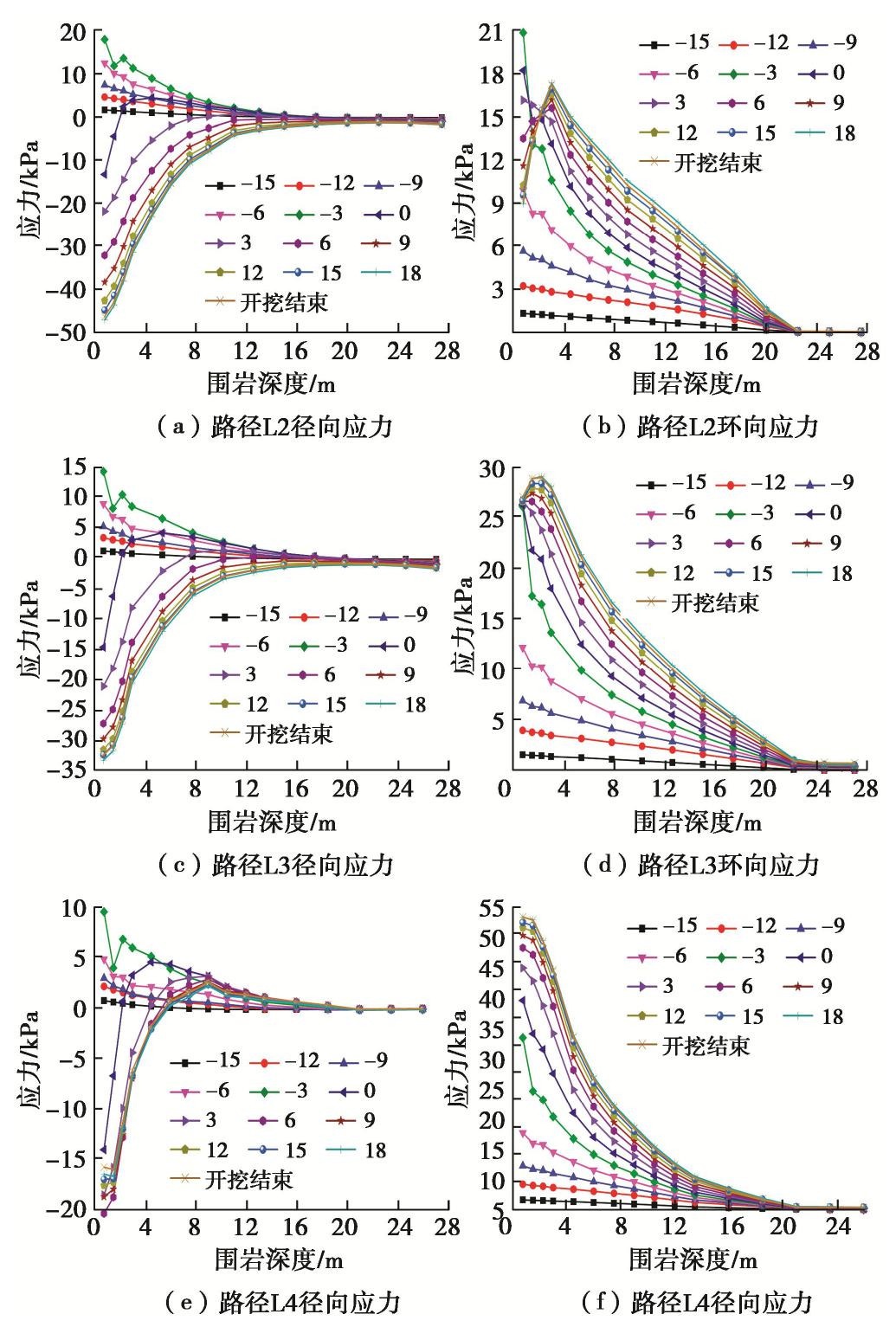

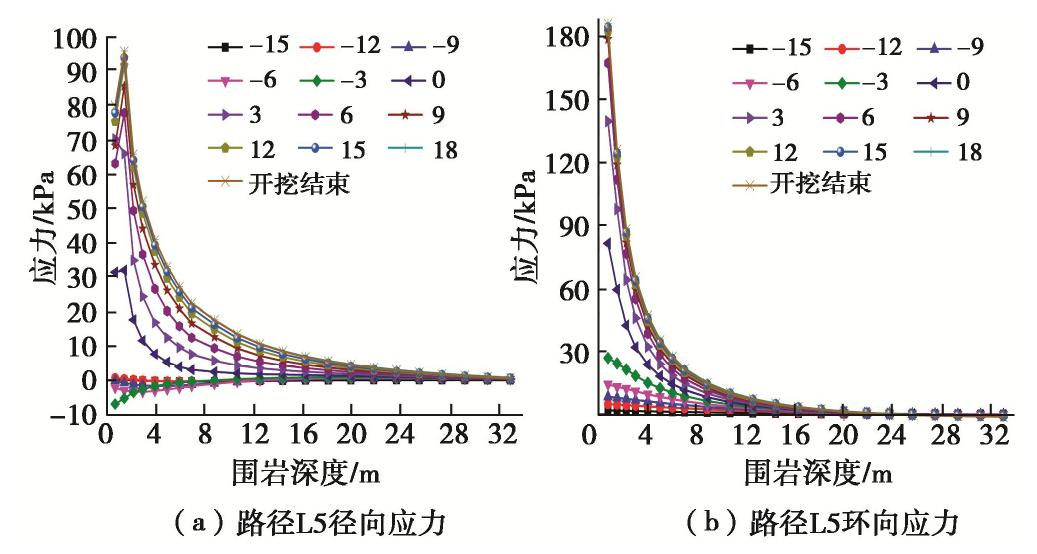

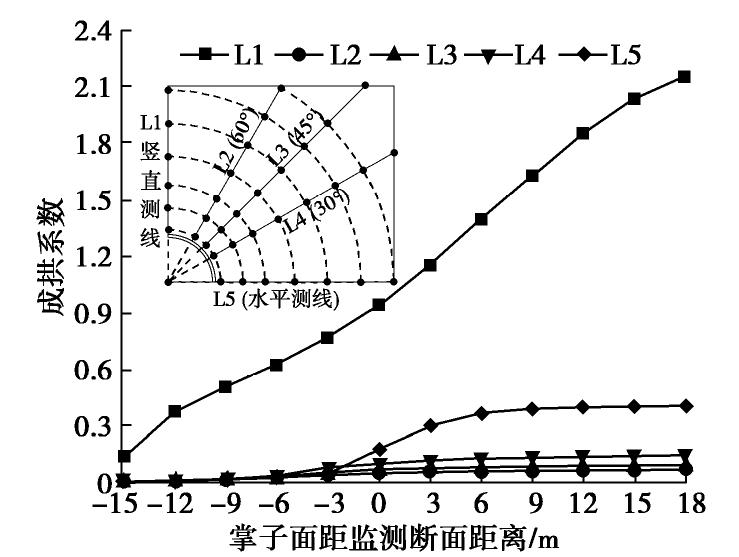

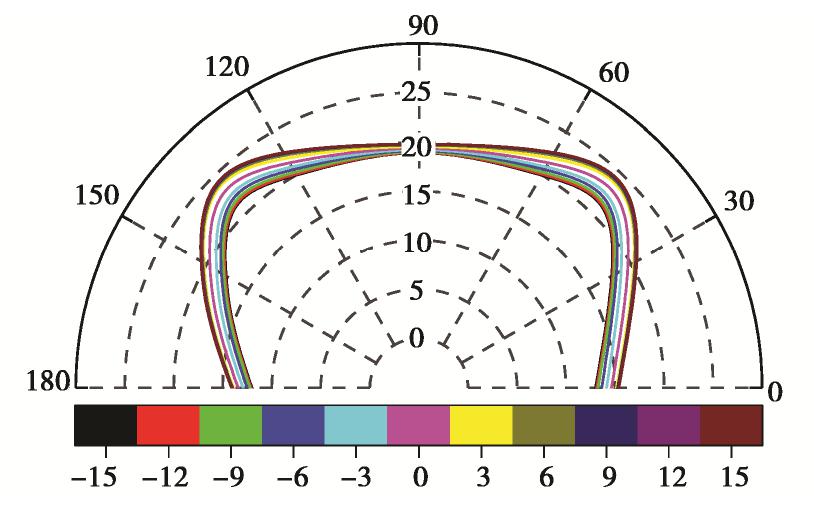

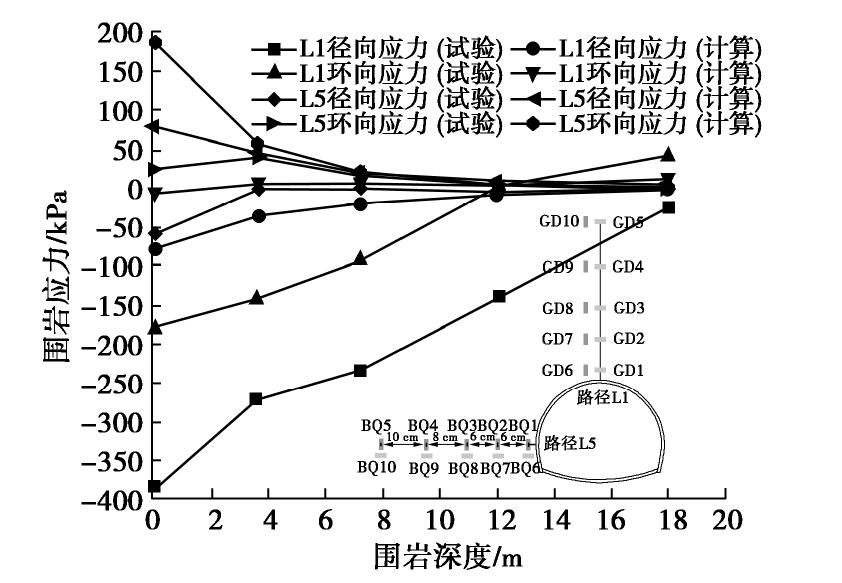

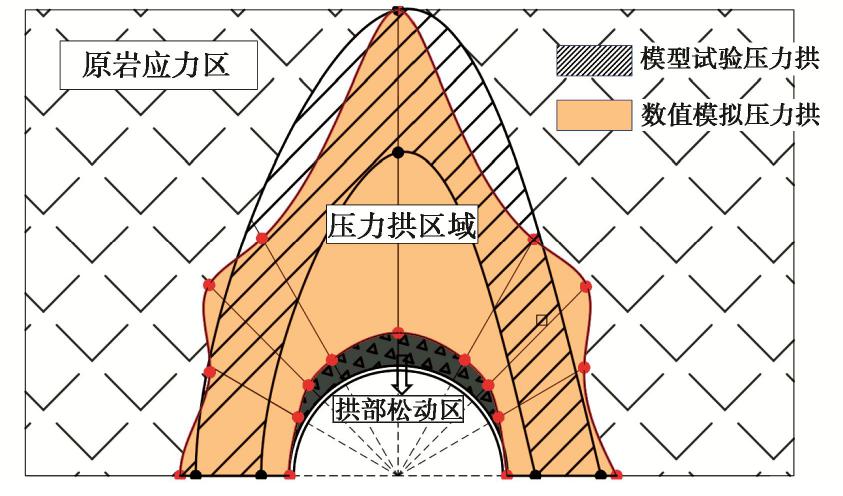

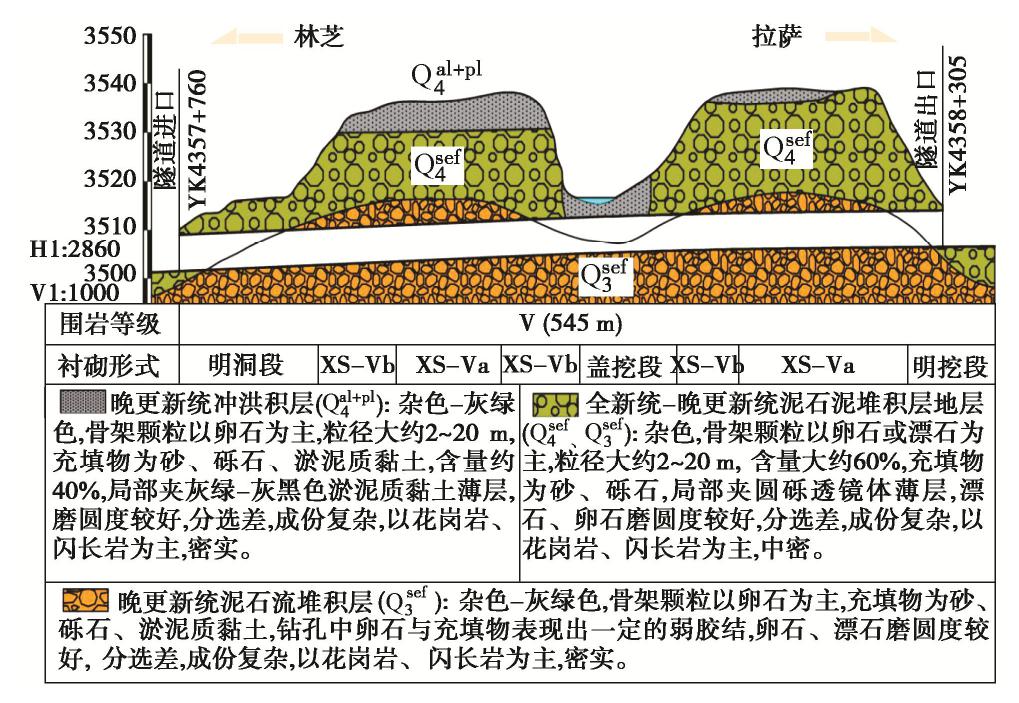

摘要: 以国道318线某堆积体隧道工程为背景,采用相似模型试验和有限元数值仿真相结合的方法研究松散堆积体隧道开挖引起的围岩应力扰动特征与压力拱形成机理,详细分析围岩径、环向应力变化及其压力拱的形成与稳定机制。结果表明:拱部围岩松动范围和松弛幅度均较大且已经延伸至地表,而边墙部位扰动深度较小但松弛幅度较大;拱部120°范围内围岩表现出明显的径向松动和环向成拱效应,边墙部位0~0.55倍开挖跨度范围内的围岩径向和环向应力显著增大形成高度应力集中区,承担着压力拱及其上的围岩荷重。围岩成拱系数具有显著的空间变化规律,其中拱顶成拱系数最大且随掌子面开挖近似呈线性增大,边墙成拱系数次之但受开挖空间效应的影响范围很小,30°~60°范围的成拱系数只在掌子面前后6 m范围内开挖时增长较大但很快便趋于稳定;试验和计算压力拱形状均呈尖拱形,它的形成对于维持洞室的稳定和减小支护结构的受力具有十分重要的意义。Abstract: A tunnel in loose deposits, located in the National Highway No. 318, is referenced to investigate the stress disturbance characteristics and mechanism of pressure arch through a combination of physical tests and numerical simulations. The radial and circumferential stresses, formation and stability mechanism of the pressure arch are analyzed. The results show that the loose zone and extent of rock mass are larger and extend to the surface at tunnel arch, whereas a smaller zone and a larger extent are observed at tunnel sidewall. The rock mass within 120° at the arch shows an obvious radial loosing and circumferential arching effect. The rock mass within the range of 0~0.55 times the excavation span is identified to be the pressure-arch zone at the sidewall where the radial and circumferential stresses obviously increase, resulting in a high-stress concentration zone to bear the load of pressure arch and its surrounding rock. The arching coefficient has a significant spatial variation, meanwhile, it increases linearly with tunnel excavation and has the largest value at the vault, followed by that at the sidewall, in which the excavation space effect shows a marginal influence. The arching coefficient within the range of 30°~60° increases greatly when excavating within the range of 6 m before and behind the tunnel face, but it tends to be stable sooner. Both the experimental and calculated pressure arches exhibit pointed-arch shapes. Their formation is of great significance to maintaining the tunnel stability and reducing the stress of support structure.

-

Keywords:

- tunnel engineering /

- loose deposit /

- stress of rock mass /

- pressure arch /

- numerical simulation

-

-

表 1 相似材料配比

Table 1 Proportion of similar materials

(%) 组成成分 2-4目石英砂 10-20目石英砂 20-40目石英砂 150目重晶石粉 600目重晶石粉 占比 35.7 34.8 9.7 10.5 9.3 表 2 原型及模型材料参数

Table 2 Parameters of materials of prototype and model

材料参数 内摩擦角φ/(°) 黏聚力c/kPa 泊松比μ 密度ρ/(g·cm-3) 弹性模量E/MPa 原型 42.0 10.02 0.38 2.01 25 模型 41.6 13.71 0.38 1.98 0.40 表 3 围岩及支护计算参数

Table 3 Parameters of surrounding rock and support

材料 弹性模量E/MPa 泊松比 密度ρ/(g·cm-3) 黏聚力c/kPa 内摩擦角φ/(°) 围岩 25 0.38 2.01 10.02 42.0 锚杆 200×103 0.30 7.80 — — 初期支护 25.2×103 0.25 2.20 — — 二次衬砌 29.5×103 0.20 2.30 — — 表 4 压力拱内外边界比较

Table 4 Inner and outer boundaries of pressure arch

工况 拱顶路径 边墙路径 内边界 外边界 内边界 外边界 数值模拟 2 m 20 m 0 14 m 模型试验 20 cm 33 cm 6 cm 20 cm 换算原型 12 m 20 m 3.6 m 12 m 表 5 计算与实测变形对比

Table 5 Comparison between calculated and measured deformations

名称 拱部沉降/mm 水平收敛/mm 拱顶 左(右)拱肩 均值 上台阶 下台阶 均值 计算 19.2 14.8(14.8) 16.3 10.3 12.1 11.20 实测 14.7 10.2(12.8) 12.6 8.5 9.2 8.85 -

[1] 谢亦朋, 杨秀竹, 阳军生, 等. 松散堆积体隧道围岩变形破坏细观特征研究[J]. 岩土力学, 2019, 40(12): 4925-4934. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201912043.htm XIE Yi-peng, YANG Xiu-zhu, YANG Jun-sheng, et al. Mesoscopic characteristics of deformation and failure on surrounding rocks of tunnel through loose deposits[J]. Rock and Soil Mechanics, 2019, 40(12): 4925-4934. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201912043.htm

[2] 杨建周. 穿越松散堆积体围岩加固与隧道施工技术[J]. 铁道科学与工程学报, 2019, 16(5): 1266-1273. https://www.cnki.com.cn/Article/CJFDTOTAL-CSTD201905021.htm YANG Jian-zhou. Reinforcement of surrounding rock and tunnel construction through loose deposits[J]. Journal of Railway Science and Engineering, 2019, 16(5): 1266-1273. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-CSTD201905021.htm

[3] XIAO J Z, DAI F C, WEI Y Q, et al. Cracking mechanism of secondary lining for a shallow and asymmetrically-loaded tunnel in loose deposits[J]. Tunnelling and Underground Space Technology, 2014, 43: 232-240 doi: 10.1016/j.tust.2014.05.013

[4] 钟祖良, 别聪颖, 范一飞, 等. 土石混合体注浆扩散机制及影响因素试验研究[J]. 岩土力学, 2019, 40(11): 4194-4202. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201911009.htm ZHONG Zu-liang, BIE Cong-ying, FAN Yi-fei1, et al. Experimental study on grouting diffusion mechanism and influencing factors of soil-rock mixture[J]. Rock and Soil Mechanics, 2019, 40(11): 4194-4202. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201911009.htm

[5] 杨继红, 董金玉, 黄志全, 等. 不同含石量条件下堆积体抗剪强度特性的大型直剪试验研究[J]. 岩土工程学报, 2016, 38(增刊2): 161-166. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2016S2026.htm YANG Ji-hong, DONG Jin-yu, HUANG Zhi-quan, et al. Large-scale direct shear tests on accumulation body with different stone contents[J]. Chinese Journal of Geotechnical Engineering, 2016, 38(S2): 161-166. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2016S2026.htm

[6] WANG S R, LI C L, WANG Y G, et al. Evolution characteristics analysis of pressure-arch in a double-arch tunnel[J]. Tehnicki Vjesnik-Technical Gazette, 2016, 23: 181-189.

[7] KONG X X, LIU Q S, ZHANG Q B, et al. A method to estimate the pressure arch formation above underground excavation in rock mass[J]. Tunnelling and Underground Space Technology, 2018, 71: 382-390.

[8] WANG X Q, KANG H P, GAO F Q. Numerical study on the formation of pressure arch in bolted gravel plate[J]. Computers and Geotechnics, 2021, 130: 1-10.

[9] 朱合华, 黄锋, 徐前卫. 变埋深下软弱破碎隧道围岩渐进性破坏试验与数值模拟[J]. 岩石力学与工程学报, 2010, 29(6): 1113-1122. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201006006.htm ZHU He-hua, HUANG Feng, XU Qian-wei. Model test and numerical simulation for progressive failure of weak and fractured tunnel surrounding rock under different overburden depths[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(6): 1113-1122. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201006006.htm

[10] 黄锋, 朱合华, 徐前卫. 含软弱夹层隧道围岩松动破坏模型试验与分析[J]. 岩石力学与工程学报, 2016, 35(增刊1): 2915-2924. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2016S1037.htm HUANG Feng, ZHU He-hua, XU Qian-wei. Model test and analysis about loose failure of tunnel surrounding rock mass containing weak interlayer[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(S1): 2915-2924. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX2016S1037.htm

[11] 房倩, 张顶立, 王毅远, 等. 圆形洞室围岩破坏模式模型试验研究[J]. 岩石力学与工程学报, 2011, 30(3): 564-571. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201103016.htm FANG Qian, ZHANG Ding-li, WANG Yi-yuan, et al. Model test study of failure modes surrounding rock for circular caverns[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(3): 564-571. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201103016.htm

[12] 李英杰, 张顶立, 宋义敏, 等. 软弱破碎深埋隧道围岩渐进性破坏试验研究[J]. 岩石力学与工程学报, 2012, 31(6): 1138-1147. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201206008.htm LI Ying-jie, ZHANG Ding-li, SONG Yi-min, et al. Experimental research of progressive damage of surrounding rock for soft fractured deep tunnel[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(6): 1138-1147. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201206008.htm

[13] 汪成兵. 均质岩体中隧道围岩破坏过程的试验与数值模拟[J]. 岩土力学, 2012, 33(1): 103-108. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201201017.htm WANG Cheng-bing. Laboratory and numerical investigation on failure process of tunnel constructed in homogeneous rock[J]. Rock and Soil Mechanics, 2012, 33(1): 103-108. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201201017.htm

[14] 叶飞, 毛家骅, 刘燕鹏, 等. 软弱破碎隧道围岩动态压力拱效应模型试验[J]. 中国公路学报, 2015, 28(10): 76-82. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGL201510012.htm YE Fei, MAO Jia-hua, LIU Yan-peno, et al. Model test on effect of dynamic pressure arch of tunnel in soft broken surrounding rock[J]. China Journal of Highway and Transport, 2015, 28(10): 76-82. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGGL201510012.htm

[15] 郑康成, 丁文其, 金威, 等. 特大断面隧道分步施工动态压力拱分析研究[J]. 岩土工程学报, 2015, 37(增刊1): 72-77. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2015S1016.htm ZHENG Kang-cheng, DING Wen-ai, JIN Wei, et al. Experimental and numerical study on staged construction pressure arch of super large section tunnel[J]. China Journal of Geotechnical Engineering, 2015, 37(S1): 72-77. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC2015S1016.htm

[16] 崔蓬勃, 朱永全, 刘勇, 等. 考虑土拱发挥过程的非饱和砂土盾构隧道极限支护力计算方法研究[J]. 岩土工程学报, 2020, 42(5): 873-881. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202005013.htm CUI Peng-bo, ZHU Yong-quan, LIU Yong, et al. Calculation of ultimate supporting forces of shield tunnels in unsaturated sandy soils considering soil arching effects[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(5): 873-881. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202005013.htm

[17] 曲世韡. 深埋城市地铁隧道对地层变形的影响及压力拱形成规律研究[D]. 北京: 北京交通大学, 2013. QU Shi-fu. Study on Influence of Deep-buried Urban Subway Tunnel on Strata Deformation and Formation rule of Pressure Arch[D]. Beijng: Bejjing Jiaotong University, 2009. (in Chinese)

[18] 潘皇宋, 杜广印, 王坤, 等. 无衬砌黄土隧道压力拱模型试验及数值模拟[J]. 东南大学学报(自然科学版), 2019, 49(5): 949-955. https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201905019.htm PAN Huang-song, DU Guang-yin, WANG Kun, et al. Model test and numerical simulation on pressure arch of unlined loess tunnel[J]. Journal of Southeast University (Natural Science Edition), 2019, 49(5): 949-955. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DNDX201905019.htm

[19] 中交第一勘察设计研究院有限公司. 国道318林芝到拉萨段公路改造工程(二期)[R]. 西安, 2015. CCCC First Highway Consultants Co., Ltd., Reconstruction of Nyingchi-Lasa Section of National Highway 318 (Phase II)[R]. Xi'an, 2015. (in Chinese)

[20] 何珺, 张成平, 杨公标. 砂卵石地层小净距隧道渐进性破坏过程试验研究[J]. 土木工程学报, 2015, 48(增刊1): 362-367. https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC2015S1064.htm HE Jun, ZHANG Cheng-ping, YANG Gong-biao. Test study on progressive failure of closely spaced tunnel in sandy cobble ground[J]. China Civil Engineering Journal, 2015, 48(S1): 362-367. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TMGC2015S1064.htm

[21] 江权, 冯夏庭, 李邵军, 等. 高应力下大型硬岩地下洞室群稳定性设计优化的裂化-抑制法及其应用[J]. 岩石力学与工程学报, 2019, 38(6): 1081-1101. https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201906002.htm JIANG Quan, FENG Xia-ting, LI Shao-jun. Cracking-restraint design method for large underground caverns with hard rock under high geostress condition and its practical application[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(6): 1081-1101. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201906002.htm

-

期刊类型引用(21)

1. 马凯蒙,张俊儒,颜志坚,汪波. 隧道压力(承载)拱研究现状与展望. 地下空间与工程学报. 2025(02): 551-562 .  百度学术

百度学术

2. 朱宇. 基于变形控制的基坑开挖与邻近运营铁路相互影响分析. 甘肃科学学报. 2024(02): 110-116 .  百度学术

百度学术

3. 张子新,李小昌,李佳宇. 软土地层盾构掘进土体稳定性模型试验研究. 土木与环境工程学报(中英文). 2024(03): 41-51 .  百度学术

百度学术

4. 郭利民. 山区隧道浅层破坏机理及支护体系. 铁道建筑技术. 2024(05): 79-82 .  百度学术

百度学术

5. 丁祥,刘勇,韩智铭,张杰达,樊浩博,田野,马凯蒙. 基于压力拱理论的深埋节理岩体隧道围岩压力研究. 河北科技大学学报. 2024(04): 434-442 .  百度学术

百度学术

6. 秦哲,刘文龙,武发宇,韩继欢,李为腾,冯强,刘永德. 考虑层叠拱传递效应的浅埋硬岩隧道支护力研究及应用. 岩石力学与工程学报. 2024(09): 2165-2177 .  百度学术

百度学术

7. 余涛,廖杭,朱宁波,姚志刚,方勇,李希文,田青峰. 粉煤灰堆积体大断面连拱隧道失稳破坏模式及施工力学研究. 岩土工程学报. 2024(09): 1909-1918 .  本站查看

本站查看

8. 蒋荣兵,王学军,李夏,伍雨,段少龙. 超浅埋富水砂层地铁隧道开挖安全控制技术研究. 江西建材. 2024(08): 259-261 .  百度学术

百度学术

9. 陈志敏,王洪,陈骏,翟文浩,王铎斌,李文豪,蔡昀辰. 西南某岩堆体级配特征与成拱效应研究. 现代隧道技术. 2024(06): 172-181 .  百度学术

百度学术

10. 马易学. 松散堆积体隧道进口段施工数值模拟及方案比选分析. 西部交通科技. 2024(12): 160-164 .  百度学术

百度学术

11. 孙振宇,皇甫楠琦,张顶立,李沐阳,王嘉琛. 大跨度隧道预应力锚固体系协同承载的压力拱效应. 铁道标准设计. 2023(01): 10-16+24 .  百度学术

百度学术

12. 昝文博,钟宇健,王恩波,钱若霖. 泥石流堆积体隧道支护体系优化效果模拟分析. 岩土工程技术. 2023(01): 47-52 .  百度学术

百度学术

13. 刘夏冰,麻建飞,贾港帅,贺家新,王文谦. 超大跨隧道分部开挖的压力拱特性分析. 北京工业职业技术学院学报. 2023(02): 1-5+54 .  百度学术

百度学术

14. 马啸宇,戚承志,盛志刚,封焱杰,王泽帆. 压力拱厚度和地表沉降关系研究. 北京建筑大学学报. 2023(03): 54-62 .  百度学术

百度学术

15. 李同,阮仁酉,石崇,裴亚兵,孙冰岐. 黏土砾石地层隧洞开挖压力拱数值模拟研究. 三峡大学学报(自然科学版). 2023(04): 54-60 .  百度学术

百度学术

16. 昝文博,赖金星,曹校勇,冯志华,邱军领,张文接. 漂卵石隧道支护体系受力变形特性. 交通运输工程学报. 2023(04): 205-217 .  百度学术

百度学术

17. 郝勇,丁琅. 穿越断层破碎带隧道压力拱研究综述. 上海建材. 2023(05): 50-53 .  百度学术

百度学术

18. 张永杰,陈明军,邓沛宇,罗志敏,胡涛. 堆积层边坡与平行穿越隧道相互作用试验研究. 地下空间与工程学报. 2023(S2): 688-697 .  百度学术

百度学术

19. 李正伟,汪士钧,侯维永,孙彬煜,张克基. 薄层状岩石试样3D打印与力学特性试验研究. 金属矿山. 2022(03): 78-84 .  百度学术

百度学术

20. 晏莉,吕超慧,喻少华,文胜,杨海涛. 近邻双孔隧道围岩联合压力拱试验与数值分析. 北京交通大学学报. 2022(03): 103-109 .  百度学术

百度学术

21. 黄旭斌,苗喆,陆希,张凯,邓立文,张华毅. 基于压力拱理论的极软岩隧洞衬砌应力变形研究. 西北水电. 2022(05): 145-149 .  百度学术

百度学术

其他类型引用(16)

下载:

下载: