Effects of temperature on swelling characteristics of GMZ bentonite

-

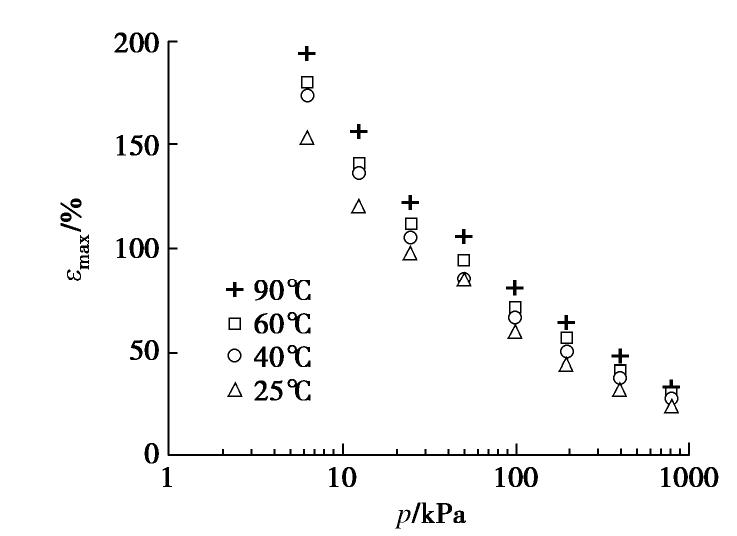

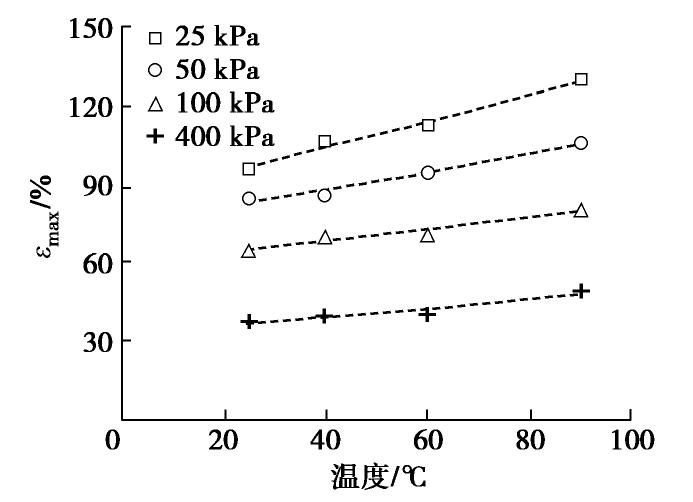

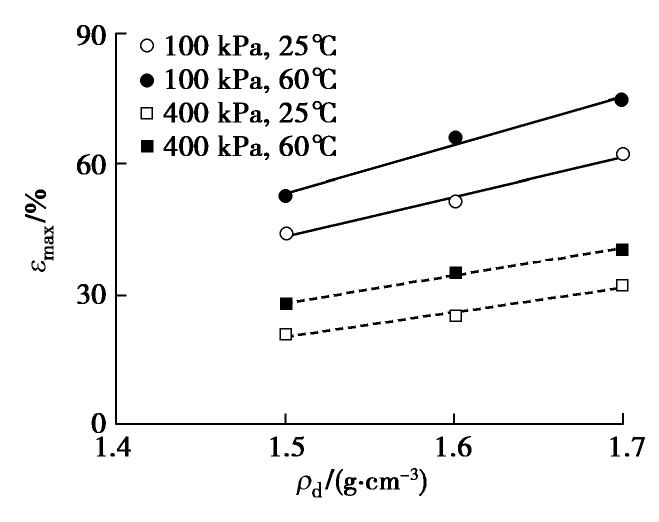

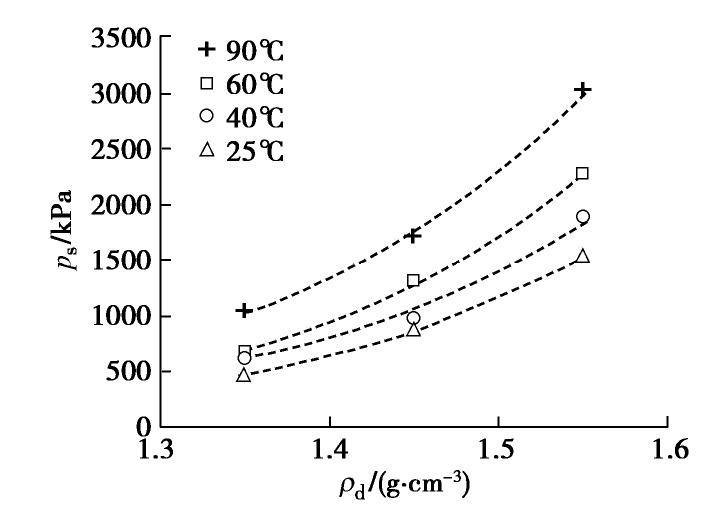

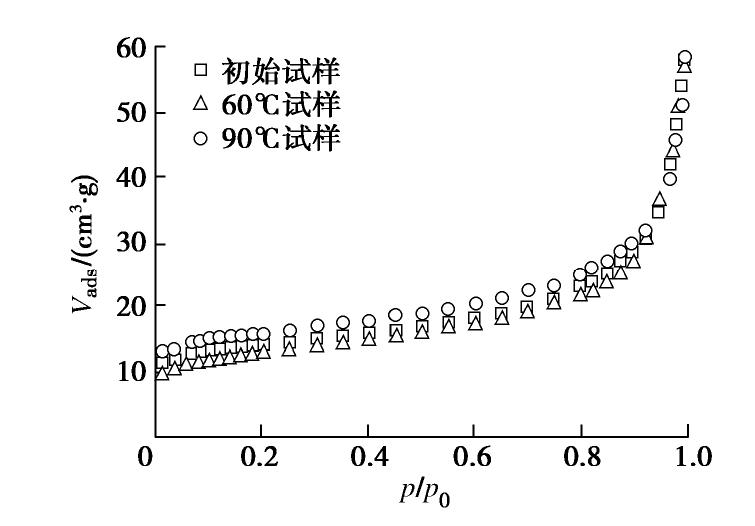

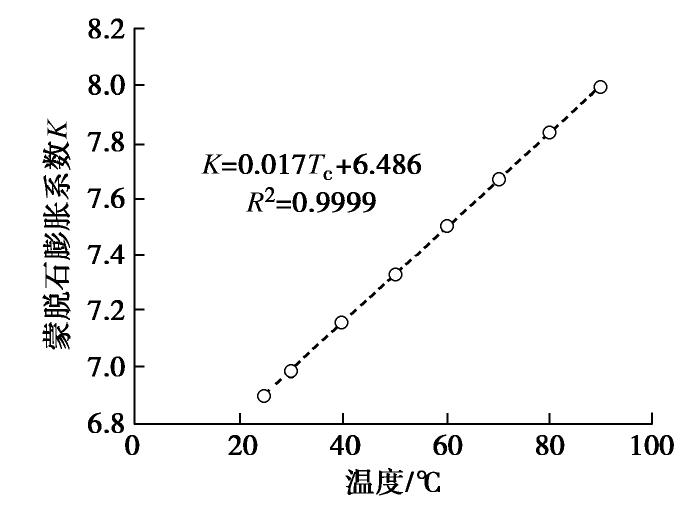

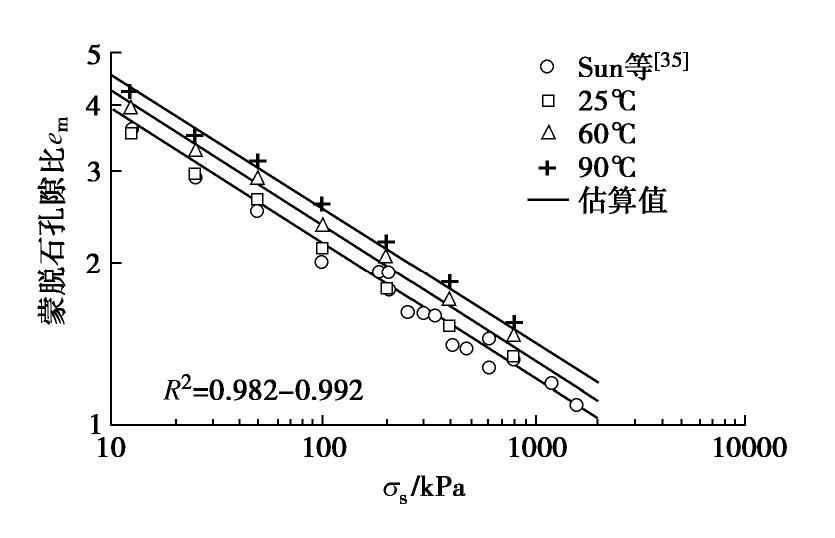

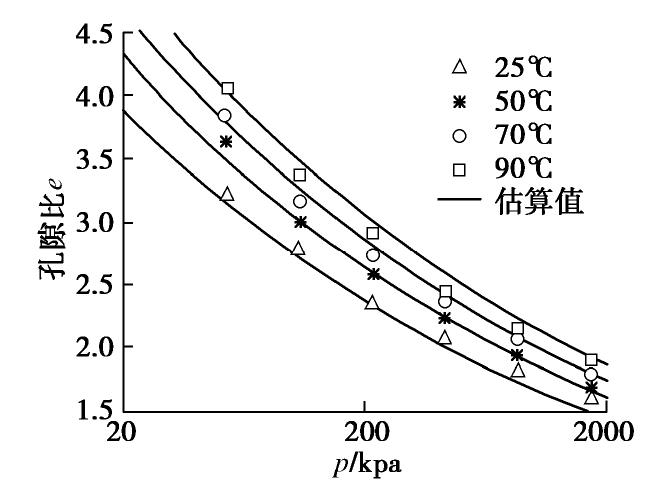

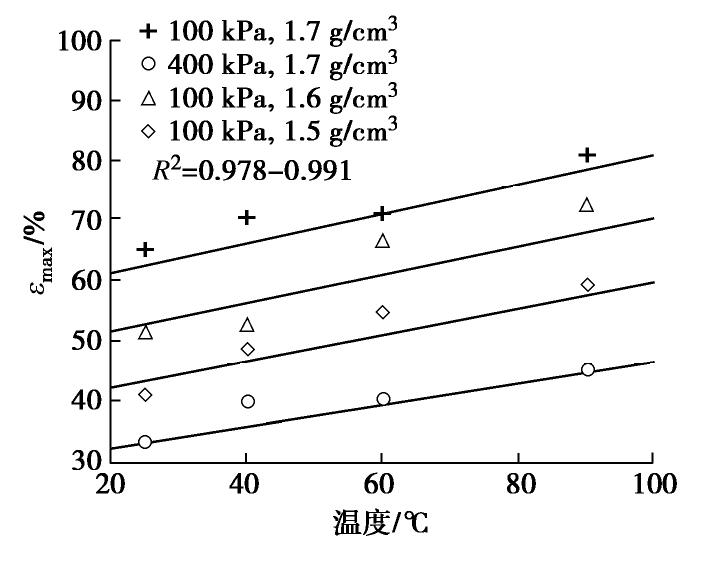

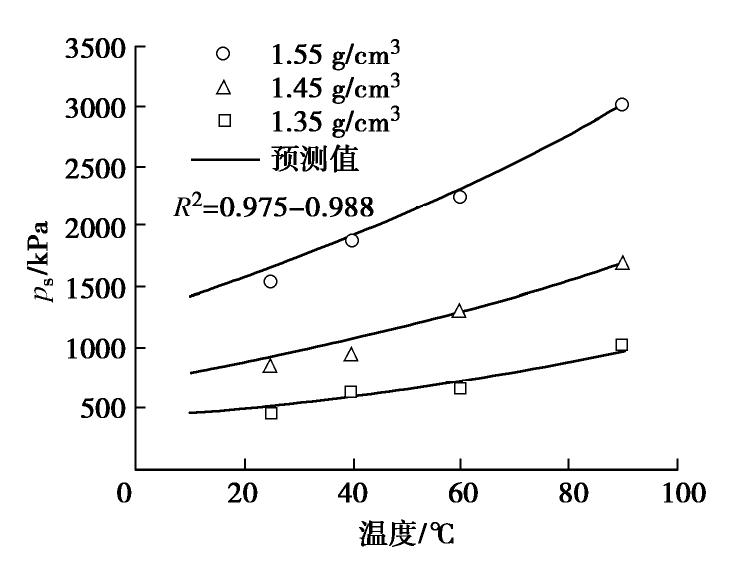

摘要: 在25℃,40℃,60℃和90℃的蒸馏水中对高庙子(GMZ)膨润土进行了膨胀性能试验。由于在试验条件下渗透膨胀占主导地位,GMZ膨润土的膨胀性能随温度的升高而增大,其中最大膨胀率随温度线性增加,而膨胀力随温度呈指数增加。压实GMZ膨润土的膨胀性能可用em=KpD-3表示。N2吸附试验结果表明温度对GMZ膨润土的表面分维D基本没有影响。在渗透膨胀条件下,采用扩散双层模型计算发现膨胀系数K与温度Tc之间存在线性关系,并且通过GMZ膨润土和Bikaner膨润土的膨胀试验进行了验证。将K-Tc线性关系与em-p分形关系相结合,提出了温度作用下GMZ膨润土膨胀性能的一种简便定量评价方法。Abstract: The buffer/backfill performance of bentonite-based materials may be affected by the influences of temperature fields, thereby leading to uncertainties in the safe operation of repositories. In order to address this issue, the swelling tests on Gaomiaozi (GMZ) bentonite are carried out in distilled water at 25, 40, 60, and 90 °C. The results show that the swelling of GMZ bentonite increases with the temperature, owing to that the osmotic swelling dominates the swelling of compacted GMZ bentonite under the experimental conditions. The maximum swelling strain increases linearly with the temperature, whereas the swelling pressure increases exponentially with the temperature. The swelling characteristics of compacted GMZ bentonite can be expressed as em=KpD-3. According to the results of N2 adsorption tests, the fractal dimension, D, of GMZ bentonite is unaffected by the temperature. Calculated by the diffuse double layer model under osmotic swelling, a linear relation is found between the montmorillonite swelling coefficient K and the temperature Tc, which is verified by the swelling tests on GMZ bentonite and Bikaner bentonite. Combining the linear K−Tc relation and the fractal em-p relation, a simple method for evaluating the swelling of GMZ bentonite affected by the temperature is proposed.

-

Keywords:

- bentonite /

- temperature /

- swelling property /

- fractal dimension /

- fractal method

-

0. 引言

不排水不排气条件下的非饱和土力学特性与公路、铁路、机场、水利、建筑等行业实际工程问题紧密相关,伴随中国基建高速发展的步伐,非饱和土不排水不排气剪切条件下的变形、强度、回弹模量变化特性研究显得较为重要。近年来非饱和土理论、试验、工程方面得到了高速发展。如陈正汉等[1]以压实黄土为对象,系统研究了非饱和黄土渗气性、渗水性、孔隙水压和孔隙气压在三轴不排水不排气剪切过程中的演化特性,苗强强等[2]对广佛高速非饱和含黏砂土的水气运移规律和力学特性进行了系统研究,杨松等[3]对云南非饱和红黏土的不排气、不排水三轴剪切特性进行了试验研究,刘文化等[4]借助于数值模拟研究了不排水条件下非饱和土水力-力学耦合特性对非饱和土的不排水、不排气三轴剪切特性进行预测,詹良通等[5]对深圳花岗岩风化料弃土快速堆填过程中不排水抗剪强度进行了评估。与此同时,回弹模量的测定和取值研究也是国内外众多道路科研机构和施工单位长期关切的问题。2002年,由美国材料试验协会(ASTM)举办路面材料回弹模量研讨出版了论文集[6]。在AASHTO2002路面设计指南中[7],考虑了湿度对路基回弹模量的影响。WAI用干湿循环模拟路基土湿度变化[8-9],湿度增大,路基回弹模量减小;干湿循环对路基回弹模量也有影响。杨树荣等[10]利用MTS动力三轴试验系统,探讨了非饱和黏性路基土之回弹模量特性及基质吸力对回弹模量之影响。李丹枫等[11]提出了基于便携式落锤弯沉仪模量控制的路基承载力动态力学指标评价方法。刘君等[12]对3类计算模型的可靠性及适用性进行对比评价。

综合国内外研究现状,对非饱和土不排水不排气三轴剪切试验孔压、体变、回弹模量等特性演化过程和机理研究还相对滞后并缺少相关配套仪器设备支撑研究试验。故本文使用自行改进的循环加卸载非饱和土三轴仪系统,探讨高速公路车辆运行过程中含黏砂土在不同含水率和压实度不排水不排气条件下,强度、变形和回弹模量变化特性。

1. 试验设备

试验设备系在后勤工程学院非饱和土三轴仪[1]的基础上改进而成的循环加卸载非饱和土三轴仪系统(图 1)。该仪器主要组成部分有非饱和土三轴双层压力室、加卸载系统、围压控制系统、反压控制系统及数据采集系统等,主要部件的特色简介如下。

(1)双层压力室,分为内压力室和外压力室,通过量测内压力室的水量变化计算试样的体积变化。内压力室试样底座上安装有高进气值陶土板,陶土板下面有螺旋槽,用以冲洗陶土板下面的气泡。

(2)轴向加载装置,采用活塞式加荷器,由空气压缩机提供压力源,用高精度气压调压阀和精密气压表控制施加的气压力。试验前用量力环对加荷器的输出压力进行了标定。加荷器可提供0~30 kN的轴向压力,相应的偏应力为0~2500 kPa。

(3)微型压力传感器(气压和水压)(图 2)。探头直径都是3 mm,用黏结剂胶接在外直径8 mm的空心螺母中。螺母下端约2 mm长的一段,用以保护传感器探头。气压传感器的引线从三轴仪底座原来安装排水管出口的地方引出。把量测气压的微型传感器装在试样帽上,从而提高了量测气压的精度,并实现了试样的小型化,这是该设备的一个重要特色。

(4)数字应变仪(图 1),分别与孔隙水压力传感器和孔隙气压力传感器连接(图 2),采集孔压数据。试验前对微型传压力感器进行了标定,传感器与应变仪在工作中性能稳定,外界干扰对其几乎无影响,压力和输出数值之间有良好的线性关系,传感器的标定曲线如图 3所示。

2. 试验研究方案

本文以广州—佛山高速公路路基含黏砂土为研究对象,其物性指标如表 1所示。该土的最优含水率为13.63%,最大干密度为1.89 g/cm3。

研究试样为重塑土样。采用后勤工程学院的重塑土制样设备和模具,把预先配制成一定含水率的土料分5层压实。试样的直径为39.1 mm,高80 mm。共做了2类21个试验:①12个不排水不排气三轴剪切试验,控制1.85 g/cm3,含水率分别为10.47%,13.63%,14.5%和16.02 %,控制分别围压为50,100,200 kPa;②9个循环加卸载条件下回弹模量试验,干密度控制为1.70,1.80,1.85 g/cm3分别对应压实度90%,95%和98%;对每一干密度配制3个含水率:10.47%,13.63%和16.02%;,试验控制围压100 kPa,最大偏应力200 kPa,采用应力控制式分6级进行加卸载。

第1类试验是为了探讨压实度和含水率在最优含水率附近变动对该土变形强度的影响,试样初始吸力为50 kPa。考虑到施加围压后试样体积压缩,饱和度提高,吸力有所降低,故可用传感器直接量测。若对含水率更低试样进行不排水剪切试验,量测吸力就需采用轴平移技术,施加适当的气压力使水压力变为正值或大于-70 kPa进行测定。为了与控制吸力的三轴试验相区别,将不排水不排气试验的围压称为总围压,用σ3表示;相应的,将该试验的平均应力称为总平均应力,用p表示。剪切速率为0.015 mm/min,剪切至轴向应变达15%需要13.5 h。

3. 试验结果及分析

3.1 不排水不排气三轴剪切试验

图 4是干密度为1.85 g/cm3的砂土在不同含水率、不排水不排气条件下,在pf–qf平面内的强度包络线关系曲线,含水率相同、不同净围压的一组实验几乎在同一直线上,可由式(1),(2)和(3)描述。

p=σ1+σ2+σ33, (1) q=σ1−σ3, (2) qf=ξ+pftanϖ。 (3) 式中p,q分别为总平均应力和偏应力;σ1,σ2和σ3是3个总主应力。pf破坏时总平均应力,qf破坏时偏应力,ξ和tanϖ分别为pf–qf平面上直线的截距和斜率。

土的不排水不排气内摩擦角、黏聚力分别由下式得出

sinφuu=3tanϖ6+tanϖ, (4) cuu=3−sinφuu6cosφuu。 (5) 图 5为含黏砂土的cuu–w关系曲线,由图 5可知,在最优含水率范围,随含水率的增加,黏聚力增加,超过最优含水率后,随含水率的提高,黏聚力逐渐减小;图 6为含黏砂土的φuu–w关系曲线,由图 6可知,在小于最优含水率时,随含水率的增加内摩擦角增大,但变化较小。超过最优含水率后,随含水率的提高,内摩擦角急剧减小。图 5,6共同反应了最优含水率是黏聚力和内摩擦角发生变化的临界值。

图 7为不同含水率时孔隙水压力和孔隙气压力随轴向应变的变化曲线,其中,图中实心符号为气压力,空心符号为水压力。图 7可知,孔隙气压力和孔隙水压力与试样的体变密切相关,试样的体变峰值点基本上对应于孔隙气压力峰值点;剪缩时孔隙气压力升高,剪胀时孔隙气压降低。含水率越大,孔隙中水分就越多,气体占据量就较少,在相同围压作用下,含水率越大试样的初始孔隙压力也就越大。随试样剪切的进行,孔隙水压力和孔隙气压力都先增大再减小;伴随剪胀的发生,孔隙气压力与孔隙水压力曲线逐渐分开,这是由于发生剪胀,含水率不变,体积增大,相应基质吸力也增大;在相同含水率时,净围压越大,孔隙气压力和孔隙水压力也越大。

由图 7(a)可以看出,3组数据气压力出现峰值早于孔隙水压力,图 7(b)几乎相同,图 7(c)孔隙水压力略早于孔隙气压力,图 7(d)明显的是孔隙水压力出现的峰值早于孔隙气压力,而本文的试样最优含水率是13.63%,出现这种现象的原因可能是在最优含水率之前土样内部流体形式是气相占优,主要决定因素是气相,而水相可能不连续,当气相气压力稳定之后挤压水相,最终水相也达到峰值点;处于最优含水率时水气两相均连续分布较好,当外力作用时,两者同时达到峰值点;当水相占优势时和气相占优势同理孔隙水压力到达峰值点先于孔隙气压力。

3.2 循环加卸载条件下回弹模量试验

在不排水不排气剪切过程中,每个试样进行两次加卸载循环,采用加卸载应力–应变滞回圈上下两端点的连线AC的斜率表示回弹模量,如图 8(a)所示。回弹模量用式(6)计算。

Et=ΔσΔε, (6) 式中,Et回弹模量,Δσ循环加卸载中应力变化,Δε循环加卸载中应变变化。

图 8为含水率10.47%时,初始压实度分别为98%,95%和90%的3个土样,经过2次循环加卸载时应力应变曲线。由图 8可以得出,相同含水率不同压实度的试样,压实度越大,试样首次加载到200 kPa时曲线越陡;滞回圈长轴连线(第一次卸载和第二次加载交点连线)斜率数值越大;随着压实度的减小,滞回圈轴向的斜率越来越小。

图 9,10分别为含水率13.63%和16.02%时,初始压实度分别为98%,95%和90%的3个试样经过2次循环加卸载时应力–应变曲线图。由该图可清晰看出,相同含水率不同压实度的试样反映的规律和图 8规律基本一致。这说明含水率一定时,压实度越大试样的回弹模量数值越大;在试验加卸载范围内,压实度小的试样所对应的滞回圈长轴连线的斜率越小;在试验含水率范围,含水率相同时,不同压实度试样回弹模量最大相差不超过2倍。从图 8~10和表 2可看出相同压实度,不同含水率的试样回弹模量相差较大,含水率10.47%和含水率16.02 %的两种土样回弹模量最大可相差接近5倍,这说明含水率对回弹模量的影响较为显著。

表 2 回弹模量汇总Table 2. Values of resilience modulus(MPa) 压实度/% 含水率/% 10.47 13.63 16.02 98 40.48 24.48 8.55 95 31.76 16.33 7.78 90 24.69 12.56 5.68 为了更深入分析三者之间的关系,将压实度与回弹模量之间采用线性关系,将含水率与回弹模量之间的关系假定为指数函数关系,其关系表达为

Et10pa=A+Bλ+Cexp((w−D)F), (7) 式中,Et回弹模量,单位为MPa,pa为标准大气压约等于0.1 MPa,λ为压实度用百分数表示,w为含水率用百分数表示,A,B,C,D,F分别为与含水率、压实度相关的拟合系数。

将含水率、压实度和回弹模量试验数据,采用origin2016自定义函数非线性多元方式(即式(7))进行拟合,得到含水率、压实度与回弹模量之间的函数关系的具体表达式如式(8)所示。其中A= -139.295,B=1.395,C=114.742,D=3.569,F=6.896,R2 =0.9121。

Et10pa=−139.295+1.395λ+114.72exp(−(w−3.569)6.896)。 (8) 式(8)拟合的曲面与试验数值之间的关系如图 11所示,拟合曲面与试验数值较为接近,拟合效果较好,说明本文所提含水率、压实度、回弹模量的函数表达式是可行的,有一定的实际推广价值和工程应用前景。

4. 结论

(1)改进的非饱和土应力控制式三轴仪系统能够满足研究非饱和土在不排水不排气条件下的强度、变形、孔压演化和循环加卸载的回弹模量试验的要求。

(2)最优含水率是土样内摩擦角、黏聚力、破坏形态发生变化的临界值;剪胀强弱与围压和含水率有密切关系,围压越大、含水率越高,剪胀性越小;随剪切的进行,孔隙水压力和孔隙气压力都先增大再减小;伴随剪胀的发生,孔隙气压力与孔隙水压力曲线逐渐分开,吸力增大。

(3)通过对试验数据分析,构建了含水率、压实度、回弹模量之间的多元非线性函数表达式,拟合结果和试验数据较为接近。

(4)非饱和含黏砂土含水率和压实度均对回弹模量有显著影响,且含水率的影响远大于干密度的影响。故在公路建设施工中,在确保压实度满足工程要求的前提下,选择合适的含水率甚为重要。

-

图 9 不同温度下GMZ膨润土的蒙脱石孔隙比估算值[13]

Figure 9. Estimation of void ratio for Bikaner bentonite under different temperatures

表 1 GMZ膨润土的物理化学指标[22]

Table 1 Physicochemical indices of GMZ bentonite

土粒相对质量密度 液限wL/% 塑限wP/% 塑性指数IP 蒙脱石含量Cm/% 阳离子交换量/(cmol·kg-1) 主要交换性阳离子/(cmol·kg-1) Na+ Ca2+ Mg2+ K+ 2.66 276 37 239 75 75.1 36.2 24.7 11.9 3.62 表 2 膨胀变形试验中试样的初始状态和试验条件

Table 2 Initial and experimental conditions of samples in swelling deformation tests

初始干密度/(g·cm-3) 初始含水率/% 温度/℃ 竖向荷载/kPa 1.70 ± 0.03 17.7~18.1 25,40,60,90 6.25,12.5,25,50,100,200,400,800 1.50 ± 0.03 17.5~17.9 25,40,60,90 100,400 1.60 ± 0.03 17.6~18.2 25,40,60,90 100,400 表 3 不同温度下膨胀系数K计算

Table 3 Calculated values of swelling coefficient K under different temperatures

Tc/℃ Z κ/m-1 u p/kPa K 25 19.172 691409134 3.456 1393.12 6.904 30 19.156 685683554 3.485 1465.08 6.992 40 19.123 674646562 3.542 1615.84 7.165 50 19.092 664125934 3.598 1775.94 7.336 60 19.061 654082622 3.652 1945.66 7.506 70 19.032 644481593 3.705 2125.26 7.673 80 19.003 635291309 3.756 2315.02 7.839 90 18.975 626483295 3.806 2515.22 8.003 -

[1] KOMINE H, OGATA N. Experimental study on swelling characteristics of compacted bentonite[J]. Canadian Geotechnical Journal, 1994, 31(4): 478-490. doi: 10.1139/t94-057

[2] 刘樟荣, 崔玉军, 叶为民, 等. 缓冲/回填材料——膨润土颗粒及其混合物研究进展[J]. 岩土工程学报, 2020, 42(8): 1401-1410. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202008007.htm LIU Zhang-rong, CUI Yu-jun, YE Wei-min, et al. Advances in researches on buffer/backfilling materials— bentonite pellets and pellet mixtures[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(8): 1401-1410. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC202008007.htm

[3] 徐永福. 考虑渗透吸力影响膨润土的修正有效应力及其验证[J]. 岩土工程学报, 2019, 41(4): 631-638. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201904006.htm XU Yong-fu. Modified effective stress induced by osmotic suction and its validation in volume change and shear strength of bentonite in saline solutions[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(4): 631-638. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201904006.htm

[4] CHO W J, LEE J O, KANG C H. Influence of temperature elevation on the sealing performance of a potential buffer material for a high-level radioactive waste repository[J]. Annals of Nuclear Energy, 2000, 27(14): 1271-1284. doi: 10.1016/S0306-4549(99)00124-3

[5] 李晓月, 徐永福. 盐溶液中膨润土峰值剪切强度的计算方法[J]. 岩土工程学报, 2019, 41(5): 885-891. https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201905014.htm LI Xiao-yue, XU Yong-fu. Calculation of peak shear strength of bentonite in salt solutions[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(5): 885-891. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTGC201905014.htm

[6] 张虎元, 崔素丽, 刘吉胜, 等. 混合型缓冲回填材料膨胀力试验研究[J]. 岩土工程学报, 2010, 31(10): 3087-3095. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201010011.htm ZHANG Hu-yuan, CUI Su-li, LIU Jie-sheng, et al. Experimental study of swelling pressure of compacted bentonite-sand mixture[J]. Chinese Journal of Geotechnical Engineering, 2010, 31(10): 3087-3095. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201010011.htm

[7] SUN W J, ZONG FEI Y, SUN D A, et al. Swelling prediction of bentonite-sand mixtures in the full range of sand content[J]. Engineering Geology, 2017, 222: 146-155. doi: 10.1016/j.enggeo.2017.04.004

[8] LLORET MORANCHO A, VILLAR M V, SANCHEZ M, et al. Mechanical behaviour of heavily compacted bentonite under high suction changes[J]. Géotechnique, 2003, 53: 27-40. doi: 10.1680/geot.2003.53.1.27

[9] HERBERT H J, KASBOHM J, SPRENGER H, et al. Swelling pressures of MX-80 bentonite in solutions of different ionic strength[J]. Physics and Chemistry of the Earth, Parts A/B/C, 2008, 33: 327-342. doi: 10.1016/j.pce.2008.10.005

[10] 项国圣, 姜昊, 徐永福. 压实膨润土膨胀变形的分形计算方法[J]. 岩土力学, 2015, 36(4): 1009-1014. https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201504015.htm XIANG Guo-sheng, JIANG Hao, XU Yong-fu. Fractal calculation method for swelling deformation of compacted bentonite[J]. Rock and Soil Mechanics, 2015, 36(4): 1009-1014. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YTLX201504015.htm

[11] PUSCH R. Swelling Pressure of Highly Compacted Bentonite[R]. Stockholm: Swedish Nuclear Fuel Supply Co, 1980.

[12] BAG R, RABBANI A. Effect of temperature on swelling pressure and compressibility characteristics of soil[J]. Applied Clay Science, 2017, 136: 1-7. doi: 10.1016/j.clay.2016.10.043

[13] CHEN Y G, DONG X X, ZHANG X D, et al. Combined thermal and saline effects on the swelling pressure of densely compacted GMZ bentonite[J]. Applied Clay Science, 2018, 166: 318-326. doi: 10.1016/j.clay.2018.10.001

[14] PUSCH R, KARNLAND O, HOKMARK H. GMM-Ea General Microstructural Model for Qualitative and Quantitative Studies of Smectite Clays[R]. Stockholm: Swedish Nuclear Fuel Supply Co, 1990.

[15] LIU L. Prediction of swelling pressures of different types of bentonite in dilute solutions[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2013, 434: 303-318. doi: 10.1016/j.colsurfa.2013.05.068

[16] 陈永贵, 蒯琪, 叶为民, 等. 高压实膨润土膨胀力预测研究[J]. 同济大学学报, 2018, 46(12): 1628-1636. https://www.cnki.com.cn/Article/CJFDTOTAL-TJDZ201812003.htm CHEN Yong-gui, KUAI Qi, YE Wei-min, et al. Prediction of Swelling Pressure for Compacted Bentonite[J]. Journal of Tongji University, 2018, 46(12): 1628-1636. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TJDZ201812003.htm

[17] YE W M, WAN M, CHEN B, et al. Temperature effects on the swelling pressure and saturated hydraulic conductivity of the compacted GMZ01 bentonite[J]. Environmental Earth Sciences, 2013, 68(1): 281-288.

[18] CUI S, DU Y, WANG X, et al. Influence of temperature on swelling deformation characteristic of compacted GMZ bentonite-sand mixtures[J]. Journal of Central South University, 2018, 25(11): 2819-2830.

[19] ROMERO E, VILLAR M V, LLORET A. Thermo- hydro-mechanical behaviour of two heavily overconsolidated clays[J]. Engineering Geology, 2005, 81(3): 255-268.

[20] TRIPATHY S, BAG R, THOMAS H R. Enhanced Isothermal Effect on Swelling Pressure of Compacted MX80 Bentonite[M]. Cham: Springer, 2015: 537-539.

[21] VILLAR M V, LLORET A. Influence of temperature on the hydro-mechanical behaviour of a compacted bentonite[J]. Applied Clay Science, 2004, 26(1/2/3/4): 337-350.

[22] XIANG G S, XU Y F, YU F, et al. Prediction of swelling characteristics of compacted GMZ bentonite in salt solution incorporating ion-exchange reactions[J]. Clays and Clay Minerals, 2019, 67(2): 163-172.

[23] TRIPATHY S, SRIDHARAN A, SCHANZ T. Swelling pressures of compacted bentonites from diffuse double layer theory[J]. Canadian Geotechnical Journal, 2004, 41(3): 437-450.

[24] XU Y F, MATSUOKA H, SUN D A. Swelling characteristics of fractal-textured bentonite and its mixtures[J]. Applied Clay Science, 2003, 22(4): 197-209.

[25] XU Y F, XIANG G S, JINAG H, et al. Role of osmotic suction in volume change of clays in salt solution[J]. Applied Clay Science, 2014, 101: 354-361.

[26] PASTINA B, HELLÄ P. Expected Evolution of a Spent Nuclear Fuel Repository at Olkiluoto[R]. Posiva Oy, 2006.

[27] CUI S L, ZHANG H Y, ZHANG M. Swelling characteristics of compacted GMZ bentonite-sand mixtures as a buffer/backfill material in China[J]. Engineering Geology, 2012, 141: 65-73.

[28] ZHANG F, YE W M, CHEN Y G, et al. Influences of salt solution concentration and vertical stress during saturation on the volume change behavior of compacted GMZ01 bentonite[J]. Engineering Geology, 2016, 207: 48-55.

[29] SUN D A, CUI H B, SUN W J. Swelling of compacted sand-bentonite mixtures[J]. Applied Clay Science, 2009, 43: 485-492.

[30] YIN Y. Adsorption isotherm on fractally porous materials[J]. Langmuir, 1991, 7(2): 216-218.

[31] KAHR G, KRAEHENBUEHL F, STOECKLI H F, et al. Study of the water-bentonite system by vapour adsorption, immersion calorimetry and X-ray techniques: II. Heats of immersion, swelling pressures and thermodynamic properties[J]. Clay Minerals, 1990, 25(4): 499-506.

[32] XIANG G S, YE W M, XU Y F, et al. Swelling deformation of Na-bentonite in solutions containing different cations[J]. Engineering Geology, 2020, 105757.

[33] XIANG G S, YE W M, YU F, et al. Surface fractal dimension of bentonite affected by long-term corrosion in alkaline solution[J]. Applied Clay Science, 2019, 175: 94-101.

[34] KOMINE H, OGATA N. New equations for swelling characteristics of bentonite-based buffer materials[J]. Canadian Geotechnical Journal, 2003, 40(2): 460-475.

[35] SUN D A, ZHANG, J Y, ZHANG J R, et al. Swelling characteristics of GMZ bentonite and its mixtures with sand[J]. Applied Clay Science, 2013, 83: 224-230.

下载:

下载: