Centrifugal model tests study on seismic response of semi-underground LNG storage tank

-

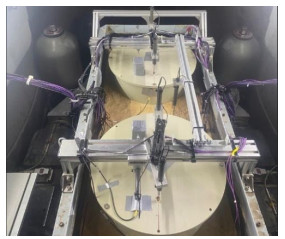

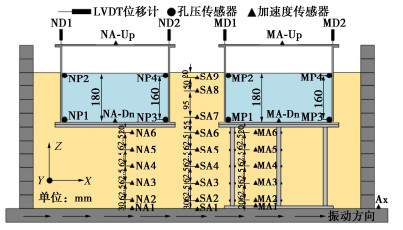

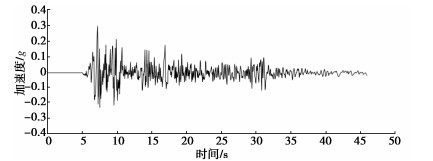

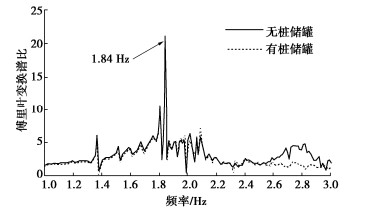

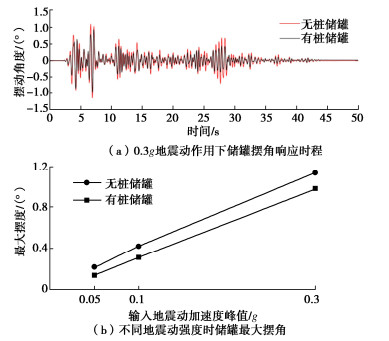

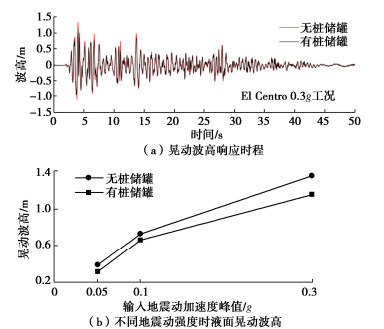

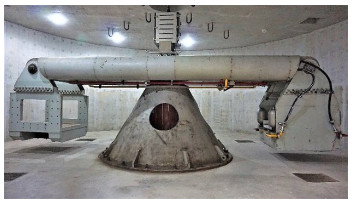

摘要: 以半地下式LNG储罐的地震响应和桩基础对半地下式LNG储罐的抗震性能影响为研究目的,设计并开展动力离心模型试验,通过对比有桩和无桩储罐的地震响应加速度、摆角、储液晃动波高等差异,验证桩基础对半地下式LNG储罐抗震性能的提升效果。结果表明:以自振周期为控制参数的大型LNG储罐离心试验设计方法满足设计原则和要求;0.05g、0.1g、0.3g El Centro波荷载下,桩基础减小了储罐罐顶5.0%~36.6%的水平加速度、13.8%~33.6%最大摆角和8.4%~18.8%储液晃动波高等地震响应,桩基础有利于提高半地下式LNG储罐的抗震性能。Abstract: In order to study the seismic response laws of a semi-underground LNG storage tank and the influences of pile foundation on its seismic performance, a dynamic centrifugal model test is designed and carried out. By comparing the acceleration, swing angle and liquid slosh wave height of pile and non-pile tanks under earthquake, the improvement effects of pile foundation on the seismic performance of the semi-underground LNG storage tank are discussed. The results show that the experimental design method for the large LNG storage tank centrifuge with natural vibration period as the control parameter meets the design principles and requirements. Under the loadings of El Centro waves of 0.05g, 0.1g and 0.3g, the pile foundation reduces the horizontal acceleration of 5.0%~36.6%, the maximum swing angle of 13.8%~33.6% and the slosh wave height of 8.4%~18.8%. The pile foundation is beneficial to improve the seismic performance of semi-underground LNG storage tank.

-

Keywords:

- LNG storage tank /

- design method /

- pile foundation /

- seismic response /

- centrifugal model test

-

-

表 1 试验模型参数

Table 1 Parameters of test model

部件 参数 原型 模型 罐体 外径/m 96 0.4 罐壁高度/m 47 0.28 罐壁厚度/mm 30 5 自振周期/s 0.575 0.01145 群桩 外径/mm 500 15.0 内径/mm 300 13.6 抗弯刚度/N·m2 1.708×109 277.846 表 2 储罐罐顶加速度响应分析特征值

Table 2 Analysis of acceleration records at tank top

地震动峰值/g 有桩罐顶加速度峰值/g 放大系数 无桩罐顶加速度峰值/g 放大系数 0.05 0.1268 2.54 0.1335 2.67 0.1 0.2040 2.04 0.2566 2.57 0.3 0.3565 1.19 0.5624 1.87 -

[1] PARK H J, HA J G, KWON S Y, et al. Investigation of the dynamic behavior of a storage tank with different foundation types focusing on the soil-foundation-structure interactions using centrifuge model tests[J]. Earthquake Engineering and Structural Dynamics, 2017, 46(14): 2301-2316. doi: 10.1002/eqe.2905

[2] SAHRAEIAN S M S, TAKEMURA J, SEKI S. An investigation about seismic behavior of piled raft foundation for oil storage tanks using centrifuge modelling[J]. Soil Dynamics and Earthquake Engineering, 2018, 104: 210-227. doi: 10.1016/j.soildyn.2017.10.010

[3] NOOR S, BEHZAD F, HOKMABADI ASLAN S, et al. Impacts of pile foundation arrangement on seismic response of LNG tanks considering soil-foundation-structure interaction[J]. Journal of Performance of Constructed Facilities, 2022, 36(1): 04021110. doi: 10.1061/(ASCE)CF.1943-5509.0001689

[4] LUO D Y, LIU C G, SUN J G, et al. Liquefied natural gas storage tank simplified mechanical model and seismic response analysis[J]. Soil Dynamics and Earthquake Engineering, 2021, 141(6): 106491.

[5] ZHAO Y, LI H N, FU X, et al. Seismic analysis of a large LNG tank considering the effect of liquid volume[J]. Shock and Vibration, 2020: 8889055.

[6] CHEN Z, XU Z, LIU Y, et al. Seismic response of a large LNG storage tank based on a shaking table test[J]. Applied Sciences, 2022, 12(15): 7663. doi: 10.3390/app12157663

[7] CHEN Z, XU Z G, TENG L, et al. Experimental and numerical investigation for seismic performance of a large-scale LNG storage tank structure model[J]. Applied Sciences, 2022, 12(17): 8390. doi: 10.3390/app12178390

[8] LUO D Y, LIU C G, SUN J G, et al. Sloshing effect analysis of liquid storage tank under seismic excitation[J]. Structures, 2022, 43: 40-58. doi: 10.1016/j.istruc.2022.06.030

[9] API 650–2013 Welded Tanks for Oil Storage[S]. Washington D C: A P Institute, 2013.

下载:

下载: